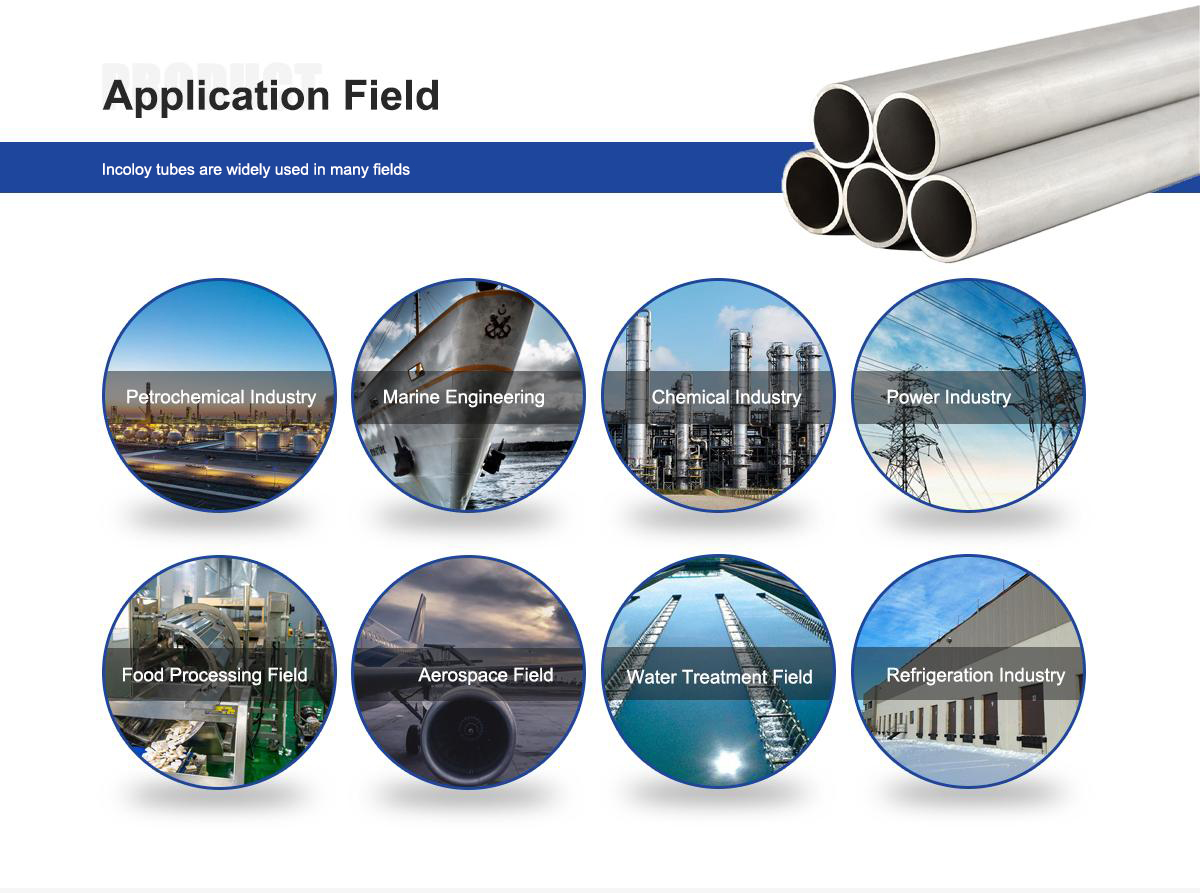

Industrial operations in chemical plants, marine systems, and offshore oil and gas platforms demand materials that can perform where others fail. Extreme pressures, corrosive chemicals, and constant exposure to seawater create conditions that quickly degrade conventional alloys. To overcome these challenges, Incoloy 925 tubes have emerged as one of the most reliable materials, offering high strength and excellent corrosion resistance in the harshest environments.

With years of expertise in nickel-based alloys, our company has become a trusted supplier of Incoloy 925 tubes for demanding global industries. We not only manufacture tubes that meet strict international standards but also tailor solutions to fit each client’s unique project requirements.

Incoloy 925 is a nickel-iron-chromium alloy that is strengthened with molybdenum, copper, and titanium. This carefully balanced composition ensures that the alloy provides both mechanical strength and corrosion resistance. Nickel gives the alloy a strong resistance to chloride-induced corrosion, while chromium enhances oxidation resistance. Molybdenum improves resistance to pitting and crevice corrosion, copper increases resistance in reducing acids, and titanium contributes to precipitation hardening, which enhances long-term strength.

This unique blend of elements means Incoloy 925 tubes can withstand the combined stresses of corrosive chemicals, seawater exposure, and high mechanical loads without compromising performance.

For more details, pls directly contact us.

Seawater corrosion is one of the toughest challenges in material selection. Chlorides in seawater accelerate pitting and stress corrosion cracking in many alloys, but Incoloy 925 tubes offer exceptional protection. They are used extensively in subsea pipelines, risers, and manifolds, where reliability under continuous immersion is critical.

For shipbuilding and marine engineering projects, Incoloy 925 tubes are ideal for seawater-cooled heat exchangers, condensers, and ballast systems. Their resistance to marine biofouling also reduces maintenance costs and downtime.

Chemical Composition Requirement

|

Item |

800 |

800H |

800HT |

825 |

925 |

|

C |

≤0.1 |

0.05-0.1 |

0.06-0.1 |

≤0.05 |

≤0.03 |

|

Mn |

≤1.5 |

≤1.5 |

≤1.5 |

≤1 |

≤1 |

|

Fe |

rest |

rest |

rest |

rest |

rest |

|

P |

-- |

-- |

-- |

≤0.02 |

≤0.03 |

|

S |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.03 |

≤0.03 |

|

Si |

≤1 |

≤1 |

≤1 |

≤0.5 |

≤0.5 |

|

Cu |

≤0.75 |

≤0.75 |

≤0.75 |

1.5-3 |

1.5-3 |

|

Ni |

30-35 |

30-35 |

30-35 |

38-46 |

42-46 |

|

Al |

0.15-0.6 |

0.15-0.6 |

0.15-0.6 |

0.2-1 |

0.15-0.5 |

|

Ti |

0.15-0.6 |

0.15-0.6 |

0.15-0.6 |

0.6-1.2 |

1.9-2.4 |

|

Cr |

19-23 |

19-23 |

19-23 |

19.5-23.5 |

19.5-23.5 |

|

Mo |

-- |

-- |

-- |

2.5-3.5 |

2.5-3.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

|

Product Form |

Standard |

|

Rod, bar & Wire |

ASTM B805 |

|

Plate, sheet & strip |

ASTM B872 |

|

Seamless pipe and tube |

ASTM B983 |

|

Forging |

ASTM B637 |

For more details, pls directly contact us.

Chemical plants involve aggressive processes such as handling sulfuric acid, phosphoric acid, and other reducing agents. Incoloy 925 tubes perform reliably in these environments due to their balanced resistance to both oxidizing and reducing conditions. They are widely used in heat exchangers, reactors, and process piping where both high strength and corrosion resistance are required.

One key advantage in chemical processing is the alloy’s resistance to stress corrosion cracking, especially in chloride-rich environments. This ensures long-term stability even in continuous contact with aggressive chemicals.

The offshore oil and gas industry is one of the largest users of Incoloy 925 tubes. Downhole tubing, flowlines, and wellhead equipment often face sour-gas conditions containing hydrogen sulfide and carbon dioxide, both of which can severely damage conventional alloys. Incoloy 925’s resistance to sulfide stress cracking and sour-gas corrosion makes it indispensable for such applications.

Additionally, its high mechanical strength ensures that it can withstand the pressures and loads encountered in deep-water drilling and production operations.

Global industrial demand is evolving, and Incoloy 925 tubes are becoming increasingly vital. Several trends drive this growth:

-

Offshore energy expansion: As oil and gas exploration moves into deeper waters, alloys with superior corrosion resistance are essential.

-

Growth in chemical processing: Emerging economies are investing in chemical plants, creating more demand for high-performance materials.

-

Stricter safety standards: Governments and regulatory bodies are enforcing tougher material requirements, especially for sour-gas and high-chloride environments.

-

Focus on sustainability: Companies aim to extend equipment lifespan, reduce replacement frequency, and minimize environmental impact—all areas where Incoloy 925 excels.

-

Marine renewable energy: Offshore wind and desalination projects are growing, requiring alloys that perform in continuous seawater contact.

Stainless steels such as duplex 2507 can be cost-effective for some seawater applications, but they lack the high-temperature resistance and long-term stability of Incoloy 925. Over time, they are more prone to stress cracking in aggressive chloride environments.

Incoloy 825 provides good corrosion resistance, but its lower strength and lack of precipitation hardening limit its use in high-pressure or high-load environments compared to Incoloy 925.

High-strength alloys like Inconel 625 offer similar corrosion resistance but are often more costly, making Incoloy 925 a more economical choice for projects requiring both strength and long-term resistance.

Comparison Table: Incoloy 925 Tube vs Alternatives

| Property | Incoloy 925 Tube | Incoloy 825 Tube | Duplex Stainless Steel 2507 | Inconel 625 Tube |

|---|---|---|---|---|

| base Composition | Ni-Fe-Cr + Mo, Cu, Ti | Ni-Fe-Cr + Mo, Cu | Fe-Cr-Ni-Mo-N | Ni-Cr-Mo + Nb |

| Corrosion Resistance | Excellent in marine & sour gas service | Very good in acid & seawater | Very good in seawater | Excellent in oxidizing/reducing |

| Strength | High (precipitation hardenable) | Moderate | High | Very High |

| Max Service Temp | ~600°C (1110°F) | ~540°C (1000°F) | ~315°C (600°F) | ~650°C (1200°F) |

| Chloride Stress Resistance | Excellent | Very Good | Good | Excellent |

| Marine Suitability | Outstanding | Good | Good | Excellent |

| Weldability | Good | Good | Good | Good |

| Typical Applications | Offshore, marine, chemical processing | Pollution control, chemical plants | Offshore rigs, pipelines | Aerospace, marine, chemical |

Every project has specific needs, and our ability to deliver customized Incoloy 925 tubes sets us apart. We supply tubes in a wide range of diameters, wall thicknesses, and surface finishes to match client specifications. Whether for subsea systems, chemical reactors, or marine infrastructure, we tailor solutions for reliable integration.

Our production process follows strict quality protocols, including ultrasonic testing, hydrostatic testing, and metallurgical analysis. These measures ensure every tube meets performance expectations before leaving our facility.

Our Advantages as a Supplier

Our company’s reputation as a trusted supplier of Incoloy 925 tubes is built on several key strengths:

-

Expertise in Nickel Alloys: Decades of experience in developing and supplying corrosion-resistant alloys.

-

Rigorous Quality Assurance: From raw material selection to final inspection, every step is tightly controlled.

-

Customization Flexibility: Tailored dimensions and finishes to suit unique project requirements.

-

Global Supply Network: Efficient logistics that ensure timely delivery worldwide.

-

Sustainability Commitment: By offering long-lasting tubes, we help clients reduce waste and lifecycle costs.

-

Customer Partnership: We provide technical support and consultation to ensure optimal material selection and application success.

These advantages enable us to deliver more than just tubing—we deliver reliability, efficiency, and peace of mind to clients operating in some of the toughest environments on Earth.

Future Outlook

As global industries push further into harsh environments, the importance of alloys like Incoloy 925 will continue to grow. The offshore oil and gas sector is expected to remain a strong driver, but chemical processing, marine renewables, and desalination will also expand the market for this alloy.

We are investing in advanced production technologies, expanding capacity, and enhancing testing capabilities to meet future demand. Our vision is to continue supporting clients with materials that combine performance, durability, and sustainability.

Incoloy 925 tubes represent a balance of strength, corrosion resistance, and long-term reliability that few alloys can match. From marine environments to aggressive chemical processing and sour-gas oilfields, they provide dependable performance where safety and efficiency are paramount.

Our role as a supplier is not just to provide tubes but to deliver solutions tailored to client needs. With expertise, quality assurance, and a commitment to sustainability, we ensure that every project equipped with our Incoloy 925 tubes achieves stable, long-lasting success.

Strong, reliable, and engineered for the harshest environments, Incoloy 925 is more than a material—it is a foundation for safe and efficient operations in chemical, marine, and offshore industries worldwide.

about Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: