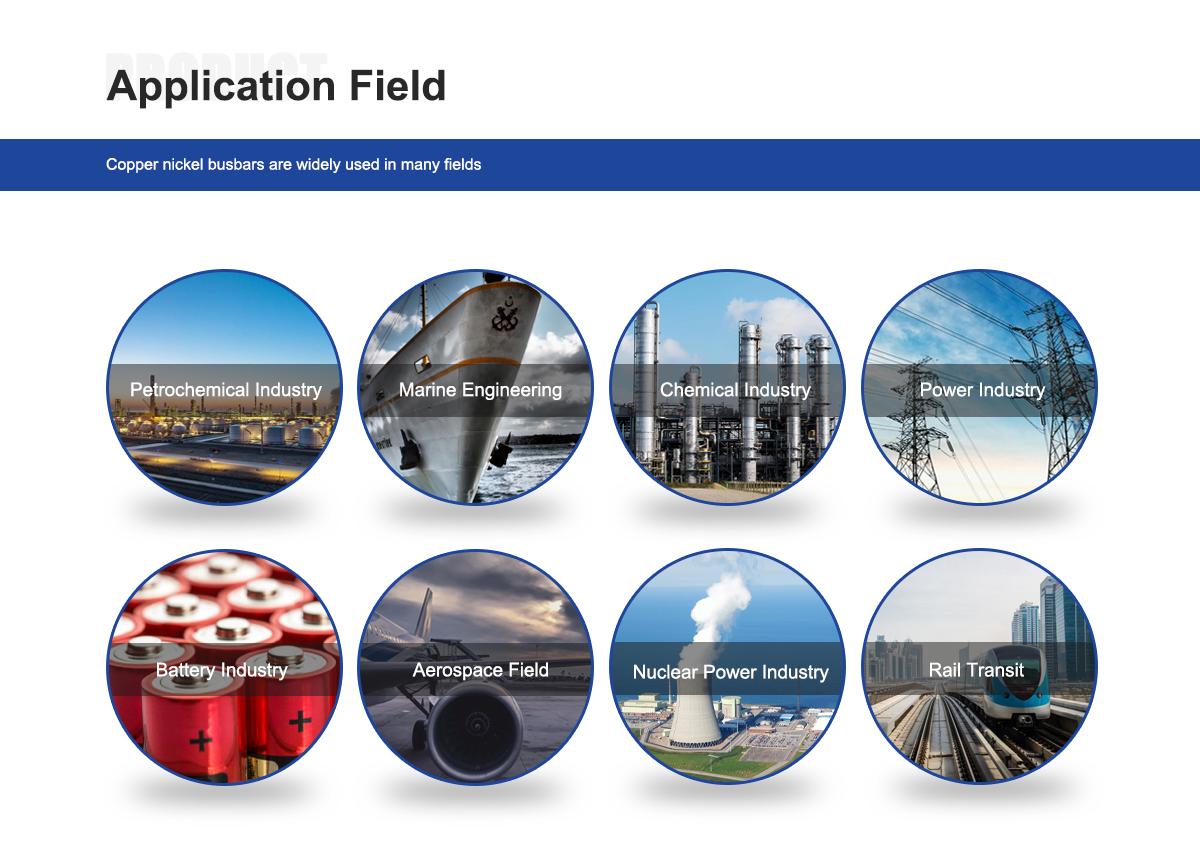

In offshore and marine projects, these busbars are used for high-current switchboards, grounding systems, and power distribution networks. Their superior corrosion resistance prevents damage from seawater, biofouling, and oxidation. Industrial applications in coastal or humid environments also benefit from their reliability and low maintenance.

DLX continuously innovates in production processes, including precision cutting, bending, surface finishing, and rigorous quality testing. Every GOST МНЖ5-1 CuNi busbar is produced to deliver consistent conductivity, mechanical durability, and corrosion resistance, ensuring long-term operational reliability for clients across the globe.

In conclusion, GOST МНЖ5-1 CuNi busbars provide a premium solution for offshore and marine electrical systems. With excellent corrosion resistance, mechanical strength, and stable electrical performance, these busbars ensure long-term reliability and reduced maintenance. DLX delivers high-quality МНЖ5-1 CuNi busbars that meet international standards, supporting industrial and marine projects with durable, corrosion-resistant electrical connections.

about Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships