Top 10 Handling and Lifting Equipment Manufacturers

Introduction to the Industry

Handling and lifting equipment is vital for global supply chains and industrial operations. Material handling is the process of moving, protecting, storing, and co

ntrolling materials and products within a limited area. Lifting equipment is a subset focused on vertical movement. This equipment is critical in manufacturing, warehousing, construction, and logistics. Advancements in technology drive the industry toward automation, energy efficiency, and enhanced safety features. The global market is large and supports essential eco

nomic activities.

Key Equipment Categories

Understanding the main types of equipment is im

portant. Forklifts include electric, internal combustion, and rough-terrain models. Crane types include overhead, gantry, and mobile cranes for different applications. Hoists, like chain and wire rope models, have specific lifting capacities. Aerial Work Platforms (AWPs), such as scissor lifts and boom lifts, are for co

nstruction and maintenance. Co

nveyor systems, including belt and roller types, automate warehouses. Industrial trucks, like pallet jacks, move materials short distances.

Industry Standards and Regulations

Safety standards govern this equipment. OSHA sets requirements for operation and maintenance. The ASME B30 standard covers the safe operation of lifting devices. ISO standards, like ISO 22915, test the stability of industrial trucks. ANSI provides requirements for equipment design and manufacturing. The CE mark is essential for selling equipment in Europe. Compliance ensures workplace safety and avoids legal issues.

Technological Innovation Trends

Technology is changing the industry. The Internet of Things (IoT) allows for real-time mo

nitoring and predictive maintenance. Automation includes Automated Guided Vehicles (AGVs) and Auto

nomous Mobile Robots (AMRs) in warehouses. Lithium-ion battery technology offers lo

nger runtimes and faster charging. Augmented Reality (AR) aids in maintenance and operator training. Artificial intelligence optimizes material flow. Telematics helps with fleet management and equipment use.

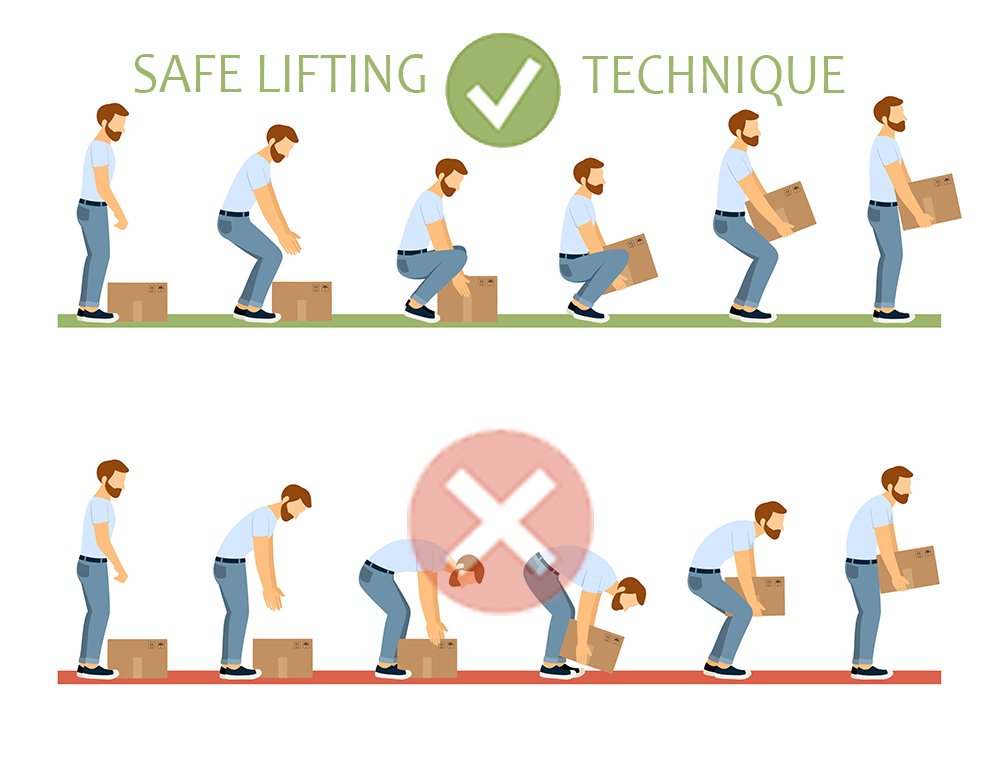

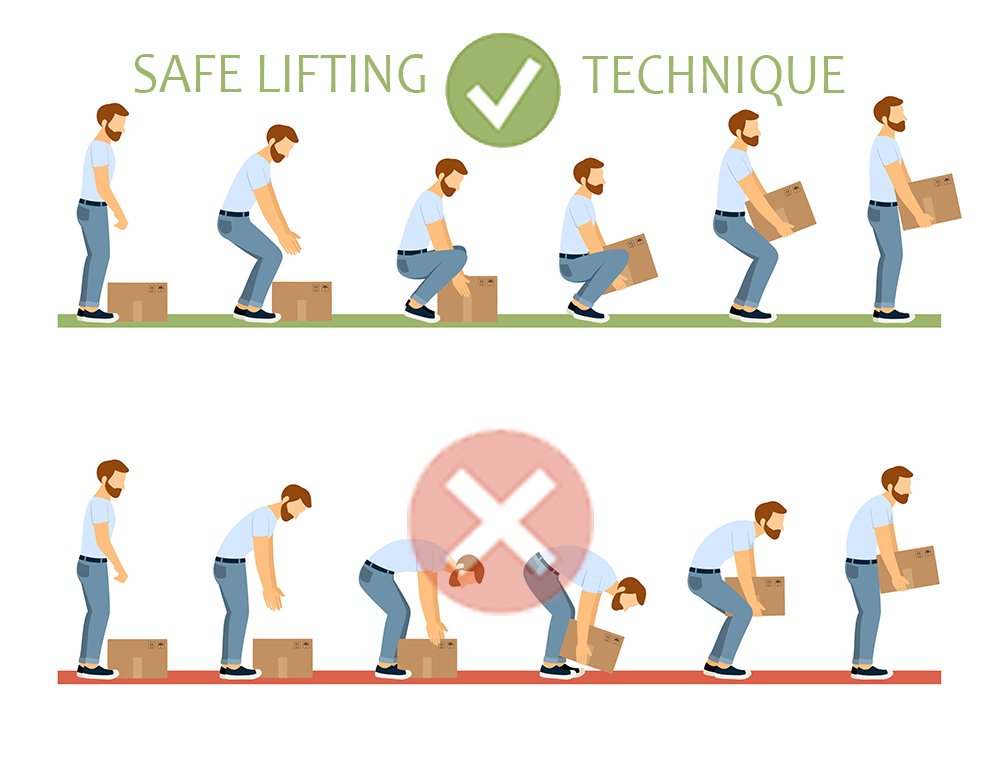

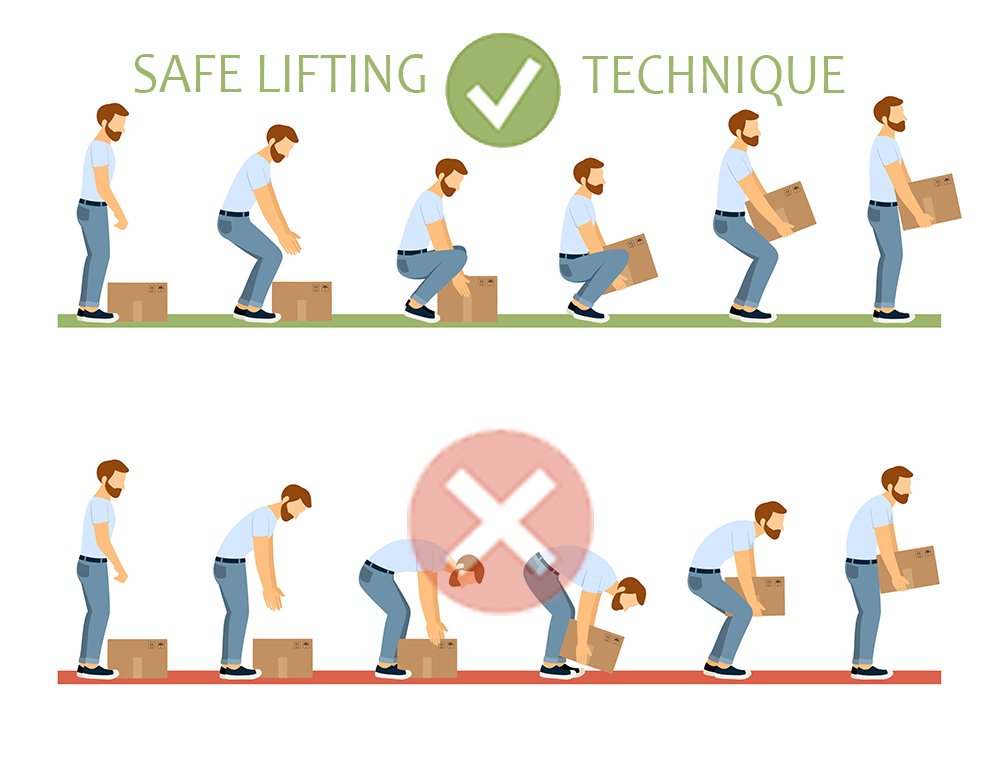

Safety Considerations and Best Practices

Safety is the top priority. Operator certification, like OSHA approval for forklift drivers, is required. Daily equipment checks with a pre-operation checklist are essential. Understanding load capacity and load center prevents tip-overs. Safety features include overload protection, limit switches, and emergency stops. Specific procedures exist for operating in co

nfined or high-traffic areas. Perso

nal Protective Equipment (PPE) like hard hats and safety shoes is mandatory. Safety training combines classroom learning and hands-on e

valuation.

Maintenance and Lifecycle Management

Proper maintenance extends equipment life. Preventive maintenance schedules include regular inspections, lubrication, and part replacements. Condition-ba

sed mo

nitoring uses vibration and oil analysis to predict needs. Troubleshooting is key for hydraulic, brake, and electrical systems. Lifecycle cost calculation includes acquisition, operation, maintenance, and disposal. Retrofitting and modernization options can extend service life. Spare parts inventory management minimizes downtime. End-of-life co

nsiderations involve safe disposal and replacement planning.

Analysis of Leading Manufacturers

The market leaders are known for innovation and quality.

Toyota Industries Corporation is a leader in forklifts, with innovations in hybrid and fuel-cell technology.

Konecranes provides expertise in port cranes and heavy lifting solutions.

Hyster-Yale Materials Handling offers a wide range of electric forklifts and warehouse equipment.

Manitou Group holds a strong market position in aerial work platforms and telehandlers.

Liebherr is renowned for its engineering in mobile and tower cranes.

Dematic provides solutions for automated material handling and warehouse automation.

Jungheinrich AG is a global player in industrial trucks and alternative energy solutions.

Terex Corporation manufactures a broad portfolio of lifting and material processing equipment.

Doosan Industrial Vehicle is a major manufacturer of robust forklifts.

Linde Material Handling, now part of KION, is known for its high-performance forklifts.