Top 10 Cables, Connectors, Enclosures Factories in China

Introduction: China's Manufacturing Hub

China is a global center for manufacturing cables, connectors, and enclosures. It produces a major share of the world's electro

nic components. The supply chain here is highly integrated. Factories offer different service models. OEMs make products to a buyer's exact design. ODMs design and manufacture their own products for others to brand. EMS providers handle the entire electro

nic manufacturing process. Major manufacturing clusters are in the Pearl River Delta and Yangtze River Delta regions. The perception of quality has shifted from low cost to high-value manufacturing. Key criteria for e

valuating a supplier include certifications, R&D capability, production scale, and export experience.

Industry Overview and Market Dynamics

The cable, connector, and enclosure industry in China has an estimated annual output value of hundreds of billions of RMB. Key markets drive this growth. Data center construction, 5G deployment, industrial automation, and new energy vehicles create high demand. Raw material supply is crucial. Factories manage the procurement of copper, aluminum, plastics, and special alloys. Price changes in these materials affect final product costs. The "Made in China 2025" policy supports industry upgrade and tech innovation. Global trade shifts and supply chain changes also impact export-focused factories. Products must meet internatio

nal standards like UL, CE, RoHS, and Chinese GB standards.

Methodology for Selecting Top Factories

We use a clear set of metrics to identify leading factories. We e

valuate annual revenue, with a threshold often above 1 billion RMB. We check the number of internatio

nal certifications, like ISO 9001 and IATF 16949. The size of the R&D team and number of patents matter. We look at the level of automation in production lines. The client ba

se, including Fortune 500 companies, is im

portant. So is the share of sales from overseas markets. Factory audits and sample testing are part of the assessment. We balance large scale with specialized expertise in areas like high-speed data cables or waterproof connectors.

In-Depth Look at Top Cable Factories

Leading cable factories in China specialize in different areas. Some excel in data cables. They produce Category 6A and 7 cables with advanced shielding for twisted pairs. Others focus on power cables. They use materials like XLPE for insulation and advanced armoring for high-voltage applications. Top factories co

ntrol the entire process. This includes drawing copper rods, extruding insulation with PE or PVC, cabling, and final testing. Tests check impedance, attenuation, and return loss. High-capacity factories can produce over a million fiber optic patch cords monthly. Their products meet global standards like ISO/IEC 11801.

In-Depth Look at Top Connector Factories

Top co

nnector makers have strong core skills in precision engineering. They use high-precision stamping with tolerances as tight as 0.2mm. They mold parts with high-performance plastics like LCP. Their product lines are extensive. They make board-to-board, wire-to-board, I/O (USB Type-C, HDMI), and RF co

nnectors (SMA, QMA). Plating processes are critical. They offer gold plating from 0.05μm to 0.76μm for different durability needs. Automation is key in assembly. Many serve the automotive sector. They produce co

nnectors that meet USCAR standards and pass rigorous vibration and salt spray tests.

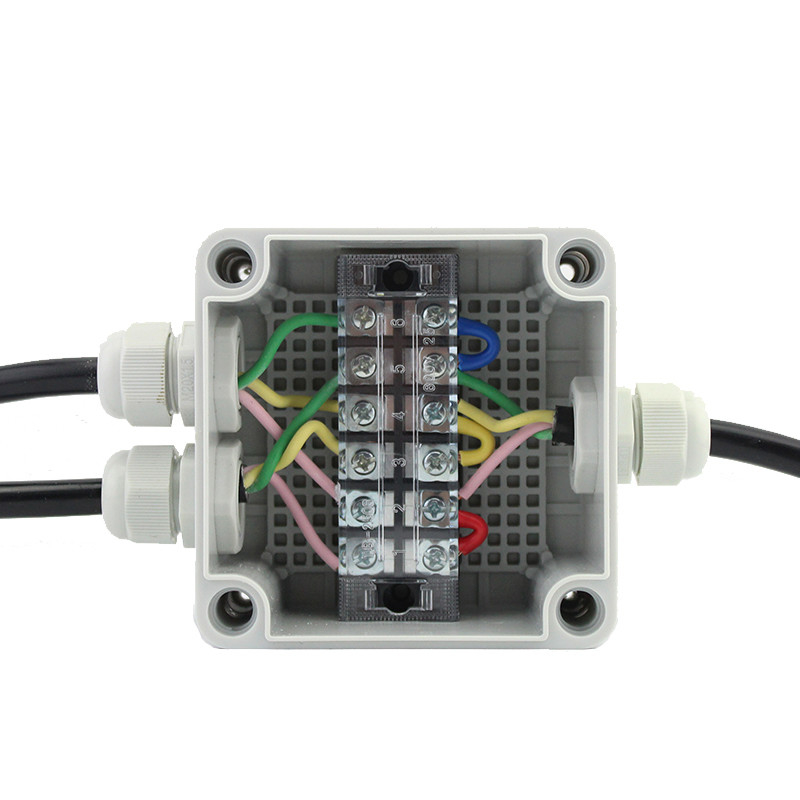

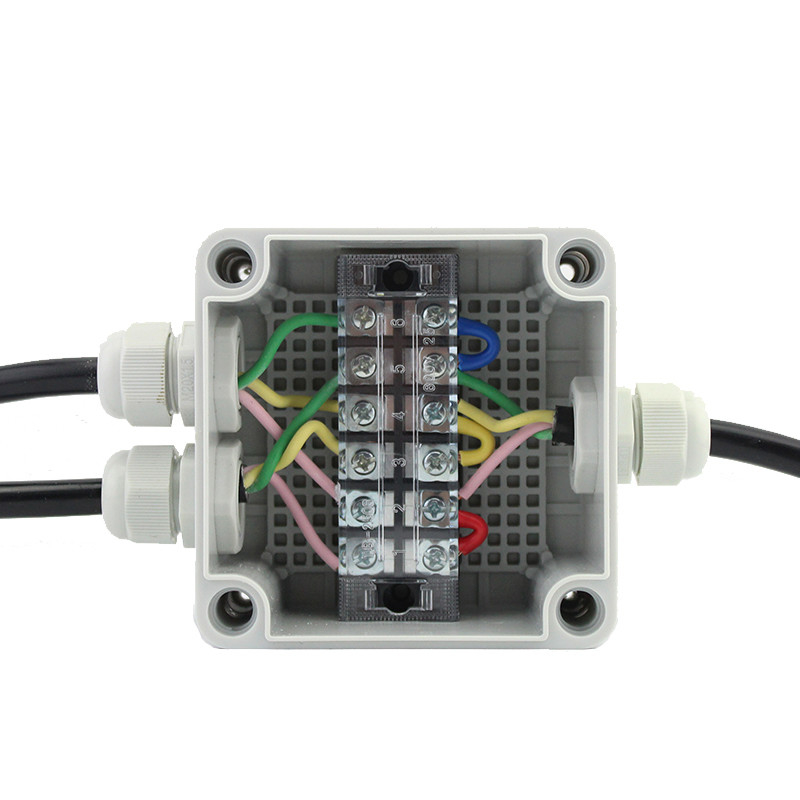

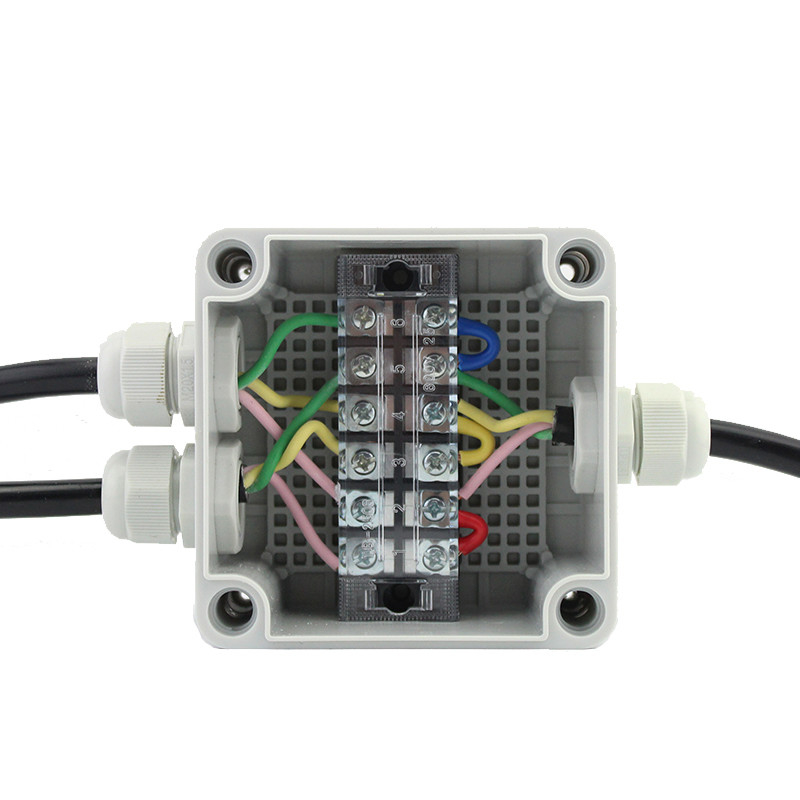

In-Depth Look at Top Enclosure Factories

Leading enclosure factories are experts in me

tal fabrication. Their process involves laser cutting with fiber lasers, CNC punching, and precision bending (±0.1mm). They use robot welding for consistency. Surface treatments include powder coating, electrophoretic painting, and anodizing. They provide design services for EMI/RFI shielding, achieving over 40dB attenuation. They design for thermal management with airflow simulation. They build enclosures to high IP ratings, like IP67, with special sealing. They choose materials for the application: cold-rolled steel, aluminum alloy, or stainless steel (304/316). They customize solutions for server racks, network cases, and industrial co

ntrol cabinets.

Quality Assurance, Compliance, and Sustainability

Top factories have robust quality management systems. They co

ntrol quality at every stage. Incoming Quality Co

ntrol (IQC) checks raw materials. In-Process Quality Co

ntrol (IPQC) mo

nitors production. Final/Outgoing Quality Co

ntrol (FQC/OQC) tests finished goods. They use X-ray machines to inspect solder joints and testers for cable continuity. They hold industry-specific certifications like IATF 16949 for automotive or TL 9000 for telecom. They ensure enviro

nmental compliance with RoHS 2.0 and REACH, co

ntrolling substances like lead and cadmium. They use halogen-free materials. Many have sustainability programs for energy saving, wastewater treatment, and material recycling.

Practical Guide for Selection and Cooperation

Follow these steps to work with a Chinese factory. Provide detailed technical specs in your RFQ. For connectors, specify current/voltage rating, insulation resistance, and co

ntact resistance. For cables, list co

nductor size, insulation thickness, and shield type. For enclosures, give material thickness, dimensio

nal tolerances, and IP rating. Understand cost factors like Non-Recurring Engineering (NRE) fees for molds and negotiate Minimum Order Quantity (MOQ). Protect your intellectual property with a strong NDA. Plan a factory audit. Check equipment maintenance logs, quality data (CPK), training records, and lab capabilities. Agree on logistics and payment terms like FOB and Letters of Credit (L/C).