Top 10 Filters and Separators Manufacturers

Filters and separators are vital components in modern industry. They ensure process efficiency, product quality, and environmental compliance. A filter uses a porous medium to remove solid particles from a fluid. A separator divides immiscible components, like oil and water, using density differences or centrifugal force. The global market is driven by energy, chemical, and water treatment industries. It is projected to reach billions of dollars by 2027. Choosing a reliable manufacturer is critical for handling harsh conditions like high temperature, high pressure, and corrosive media. This list evaluates top manufacturers based on innovation, product range, industry application, and sustainable practices.

Technical Standards and Certifications

evaluating a manufacturer requires checking key technical parameters. These include filtration rating (from micron to nano scale), flow capacity (up to thousands of cubic meters per hour), and pressure drop characteristics. ISO 9001 for quality management and ISO 14001 for environmental management are essential certifications. Compliance with ASME BPVC is mandatory for high-pressure vessels. Industry-specific standards like API 610 for pumps and API 12J for oil and gas separators are also critical. Material compatibility tests, such as NACE MR0175 for sour environments, are a must. Modern systems integrate digital features like IoT sensors for predictive maintenance.

Energy Industry Application Leaders

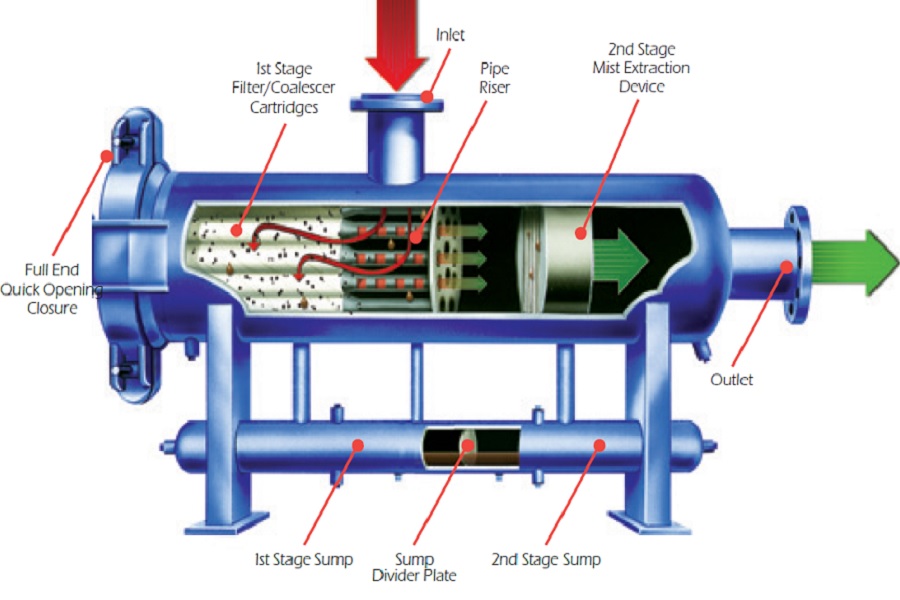

Several manufacturers lead in serving the oil and gas sector. They provide technology for processing high-sulfur crude oil. Three-phase separators efficiently split oil, gas, and water. For offshore platforms, compact cyclone separators face design challenges like anti-surge and space optimization. Adsorption filters with molecular sieves dehydrate natural gas to a dew point of -40°C. In shale gas extraction, micron-rated ceramic filters treat flowback water. Nuclear power plants use HEPA filters that meet strict standards. Key players in this space offer advanced products like coalescing separators and plate separation systems.

Water Treatment and Environmental Solutions Experts

Specialist manufacturers focus on innovations for water and wastewater. Reverse Osmosis (RO) membrane technology achieves over 99% salt rejection in desalination. Membrane Bioreactors (MBR) integrate biological treatment with microfiltration in municipal plants. To remove emerging contaminants like PFAS, manufacturers use activated carbon filters and ion exchange systems. Automatic self-cleaning filters reduce water consumption in industrial cooling loops. These experts also enable resource recovery in a circular economy, such as extracting phosphorus from wastewater.

Chemical and Pharmaceutical Precision Filtration

This sector demands high purity and strict compliance. Manufacturers supply absolute-rated filters that meet GMP standards for sterile conditions. Single-Use Technology (SUT) is growing in biopharma for filtering cell culture media. Nanofiber coating technology enhances particle capture efficiency while reducing pressure drop. Chemical compatibility is key for solvent filtration, with PTFE membranes handling corrosive fluids. Other applications include microfiltration for catalyst recovery and guard filters for chromatography columns. Real-time integrity testing, like diffusion flow tests, is common.

Innovation and Sustainability Frontiers

Leading manufacturers pioneer green technologies. Energy recovery devices, like pressure exchangers in RO systems, cut energy use by 30%. Bio-based filter media, such as coconut shell carbon or bamboo fiber, reduce environmental impact. Zero Liquid Discharge (ZLD) systems use evaporator-crystallizer combinations. Smart monitoring systems employ AI algorithms to predict membrane fouling and optimize cleaning cycles. New solutions are emerging for filtering amine solvents in carbon capture. Manufacturers also adopt lifecycle assessments (LCA) and design for recyclability.

Selection and Procurement Guide

Use a practical framework to choose a supplier. Key factors are fluid properties (viscosity, particle size distribution), operating conditions (temperature, pressure), and compliance needs (FDA, USP Class VI). Calculate the Total Cost of Ownership (TCO). This includes initial investment, energy use, maintenance, and disposal costs. Audit the manufacturer’s testing facilities and customization capabilities, like CFD simulation services. Ensure they have a strong service network for quick parts delivery and technical support. When bidding, request performance guarantees and validated case studies. Consider global supply chains and regional production centers to shorten delivery times.