Top 10 Valves Factory in China

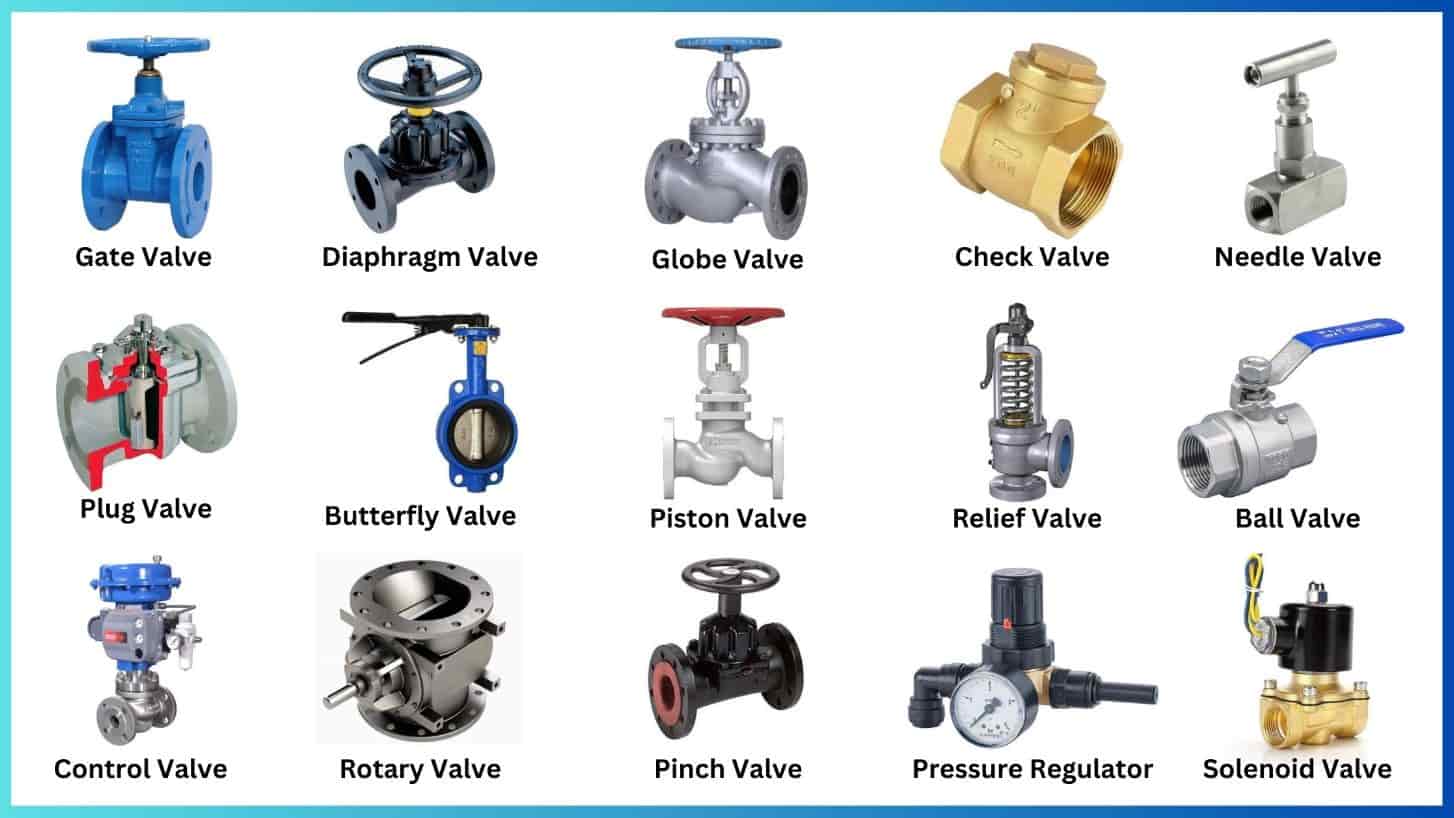

Valves are essential control components in industrial pipeline systems. They manage the flow of liquids, gases, and slurries. China is the world's largest valve manufacturer. It has a complete supply chain and advanced technical skills. Chinese valves serve many industries. These include oil and gas, power generation, water treatment, and pharmaceuticals. This list details the top ten valve factories in China. It examines their strengths and specialties.

How We Rank the Factories

We use a detailed system to rank these companies. The system looks at several key areas:

- Annual production output value (in billions of RMB).

- Certifications like ISO 9001 and API 6D/6A.

- Investment in research and development (R&D) and number of patents.

- Global market share and international project experience.

- Range of pressure ratings the valves can handle.

- Ability to work with special materials and alloys.

- Use of smart manufacturing and digital systems.

- Quality and speed of customer service and support.

Leading Technical Factories

Some factories lead the market with their technical expertise.

Jiangsu Shentong Valve Co., Ltd.This company holds over 90% of the domestic market for nuclear valves. It led the creation of the Chinese national standard GB/T 32291-2015. Its main products include nuclear gate valves, globe valves, and check valves.

Neway Valve Co., Ltd.Neway has full API 6A wellhead valve certifications. It makes valves for deep-sea applications that work at depths beyond 1,500 meters.

Suzhou High & Medium Pressure Valve Co., Ltd.This factory produces key valves for ultra-supercritical thermal power units. These valves operate at temperatures up to 620°C. They replace imported products in many Chinese power plants.

Specialist Valve Manufacturers

Some companies are experts in specific types of valves.

Chongqing Chuanyi Automation Co., Ltd.They specialize in smart control valves. Their smart positioners have an accuracy of 0.5%. They also carry SIL3 safety certification.

Shanghai Guanlong Valve Co., Ltd.Guanlong makes large valves for water treatment projects. Their valves were used in China's South-North Water Transfer Project. They can make valves with diameters up to 3.6 meters.

Zhejiang Petrochemical Valve Co., Ltd.This company focuses on valves for hydrogenation reactions. Their valves handle pressure ratings up to 2500LB. They use special materials that resist hydrogen damage.

Dalian DV Valve Co., Ltd.DV Valve is a leader in nuclear valves. Its main steam isolation valves for nuclear islands are certified by the national nuclear safety agency. They have a design life of 60 years.

Factories with Strong Global Sales

These companies have a significant presence in international markets.

China SUFA Technology Industry Co., Ltd.SUFA exports products to 56 countries. It supplied all the nuclear-grade valves for the Chashma Nuclear Power Plant in Pakistan.

Yuanda Valve Group Co., Ltd.Yuanda has storage centers in the USA and the Middle East. Its annual export value exceeds $200 million USD.

AMICO Valve Co., Ltd.AMICO valves have EU CE marking and UK WRAS certification for drinking water. This allows them to supply valves for municipal water projects across Europe.

Comparing Innovation

Innovation is key for these top factories. Together, they operate 8 national-level enterprise technology centers. They have helped to write 47 international and national standards. Smart valves now make up 35% of their new production. They work with top universities like Tsinghua and Xi'an Jiaotong on research. They use new materials, like zirconium, for highly corrosive environments. Their testing labs can handle pressures up to 10,000 PSI.

A Guide for Buyers

Choosing the right valve is important. Consider the fluid it will control. Think about its corrosiveness, thickness, and if it contains solids. Higher pressure ratings (from 150LB to 2500LB) increase the cost. Look at the total cost of owning the valve, not just the purchase price. This includes maintenance and energy use. The market for smart valves is growing by 12% each year. Ceramic valves are becoming more popular for abrasive uses. Check the supply of key raw materials, like cobalt alloy. Finally, consider the factory's commitment to green manufacturing standards.