Top 10 Furnaces and Heat Treatment Factories in China

China is a major global center for industrial furnace and heat treatment equipment manufacturing. The industry has a complete supply chain and advanced technical capabilities. Heat treatment is a key industrial process. It changes material properties by controlling heating and cooling. This technology is vital for aerospace, automotive, tool making, and energy sectors. Chinese factories serve both the domestic market and export worldwide. They offer everything from standard furnaces to custom solutions.

Technical Capabilities and Innovation

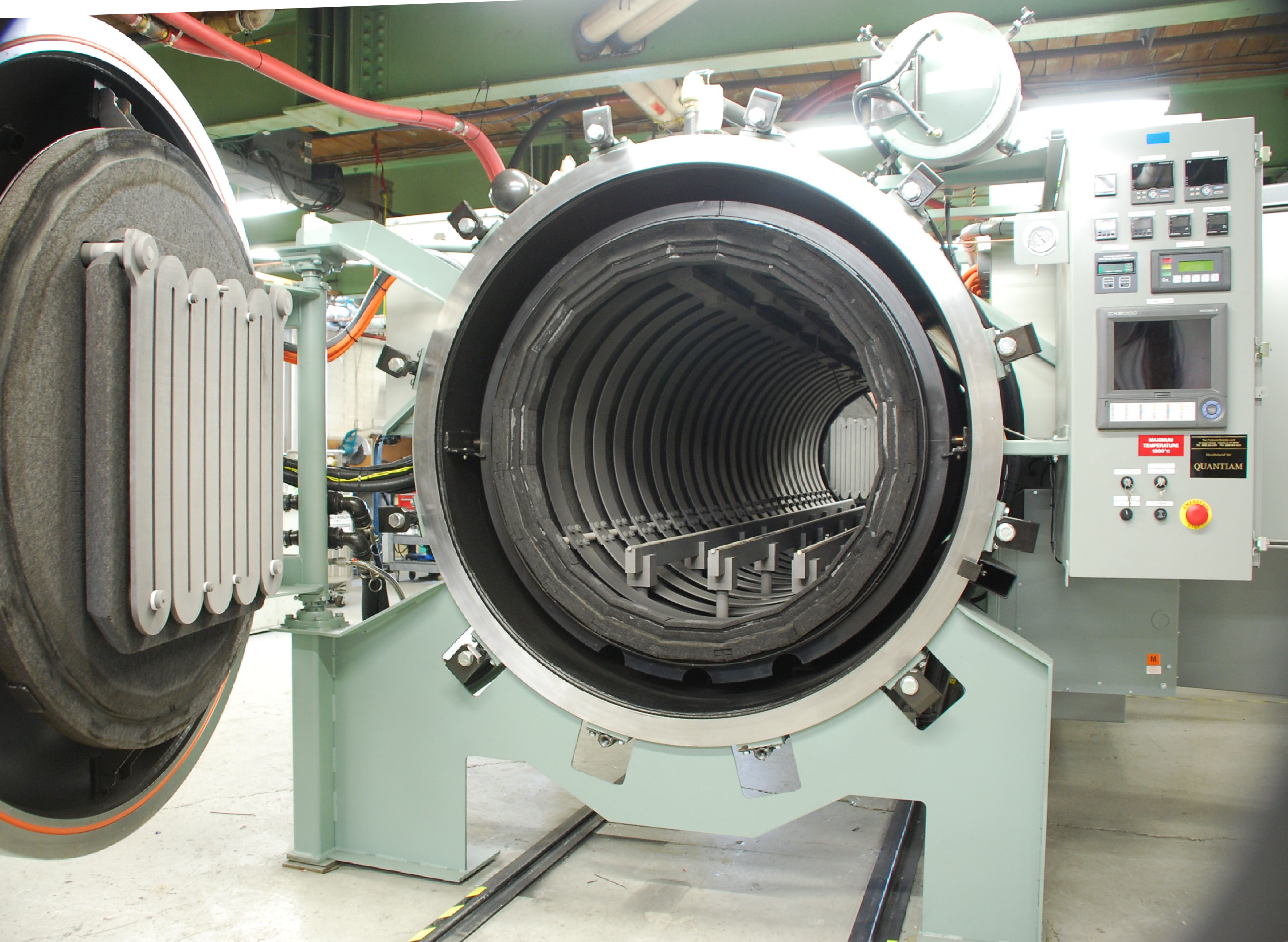

Leading Chinese factories invest heavily in research and development. They drive industry progress. Many have national-level R&D centers. They focus on creating high-efficiency furnaces. For example, melting furnaces with Regenerative Combustion Technology (RCT) can cut energy use by 30%. Vacuum heat treatment is another key area. Factories now produce high-vacuum furnaces with pressure below 10-3 Pa for precision alloys. Smart control systems use Internet of Things (IoT) tech. They allow real-time monitoring and predictive maintenance. Precise temperature control within ±3°C improves product quality. Several factories help set national standards, like the GB/T 10067 series. This pushes for more standardization and global reach.

Product Range and Applications

Top factories offer a wide variety of heat treatment equipment. They cover basic to high-end applications. Common types include box furnaces and pit furnaces. They are used for annealing, normalizing, and tempering. Operating temperatures range from 650°C to 1200°C. They work on carbon steel and alloy steel. Atmosphere control furnaces use nitrogen-based protection to prevent oxidation. These are common in automotive parts production. They control carburizing depth with ±0.05mm precision. Vacuum furnace series include oil quenching and gas quenching types. They treat tool steel and aerospace materials. Cooling rates can exceed 20°C per second. Continuous lines like mesh belt furnaces and pusher furnaces handle high-volume processing. Capacity ranges from 100kg to 2000kg per hour. They are often used in bearing and fastener industries.

Market Influence and Customer Cases

These factories have a strong global presence. Their customers are in many key industries. In automotive, they supply heat treatment lines to brands like Volkswagen and Toyota. These lines process gears and crankshafts to improve wear resistance and fatigue strength. Aerospace clients include COMAC. They use vacuum furnaces for titanium alloy parts, meeting AS9100 standards. The energy sector uses large rotary furnaces for wind power gear carburizing. This ensures reliability in extreme conditions. Export markets cover Southeast Asia, Europe, and the Americas. For instance, factories export smart control furnaces to Germany, proving technical competitiveness. Customer cases show that factories often provide turnkey solutions. These include installation, training, and after-sales service for global satisfaction.

Sustainability and Energy Efficiency

Environmental care and energy efficiency are core focuses. They align with global green manufacturing trends. Efficient combustion systems use low-NOx burners. Their emissions meet EU EN 746-2 standards, reducing pollution. Waste heat recovery is built into furnace designs. For example, using flue gas to preheat combustion air boosts thermal efficiency above 80%. This saves 20-30% energy compared to traditional furnaces. Development of electric furnaces, like resistance and induction heaters, uses renewable power. This supports carbon neutrality goals. Factories also use ISO 50001 energy management systems to optimize production and cut carbon emissions. A case in point is melting furnaces for aluminum processing. They consume under 500 kWh per ton of aluminum, leading internationally.

Quality Control and Certification

Strict quality control systems ensure device reliability and customer trust. They cover everything from design to production. Material selection follows international standards. For instance, using 310S stainless steel for high-temperature parts extends furnace life beyond 10 years. Temperature uniformity tests follow the AMS 2750E standard. They guarantee temperature variation within ±5°C inside the furnace. This meets strict aerospace needs. Certifications include CE, ISO 9001, and ASME. They prove products meet safety and performance requirements. Factories also offer full testing services. These include metallographic analysis and hardness testing to verify treatment results. Continuous improvement processes use customer feedback and audits to maintain high quality.

Future Trends and Industry Outlook

The Chinese heat treatment industry is moving toward smart, green, and high-end development. This shapes the future of manufacturing. Digital twin technology simulates heat treatment processes. It optimizes parameters and cuts trial-and-error costs, boosting efficiency by over 20%. Artificial intelligence (AI) integrates into control systems. It enables adaptive heating curves that auto-adjust to material type for better consistency. Green hydrogen is a potential heat source under research. It could enable zero-carbon emission heat treatment. Global expansion is speeding up. Factories set up service centers overseas for local support. Industry collaboration and mergers boost competitiveness. For example, technical partnerships with European firms develop next-generation ultra-high temperature furnaces (up to 2000°C). Looking ahead, Chinese factories will continue to lead innovation and support global manufacturing upgrades.