Top 10 Mechanical Transmission Companies

Mechanical transmission systems are the core of industrial machinery and vehicles. They transfer power from its source to the point of action. The top companies in this field lead with innovation, quality, and global market share. They serve critical sectors like automotive, aerospace, industrial manufacturing, and renewable energy.

Mechanical Transmission Basics

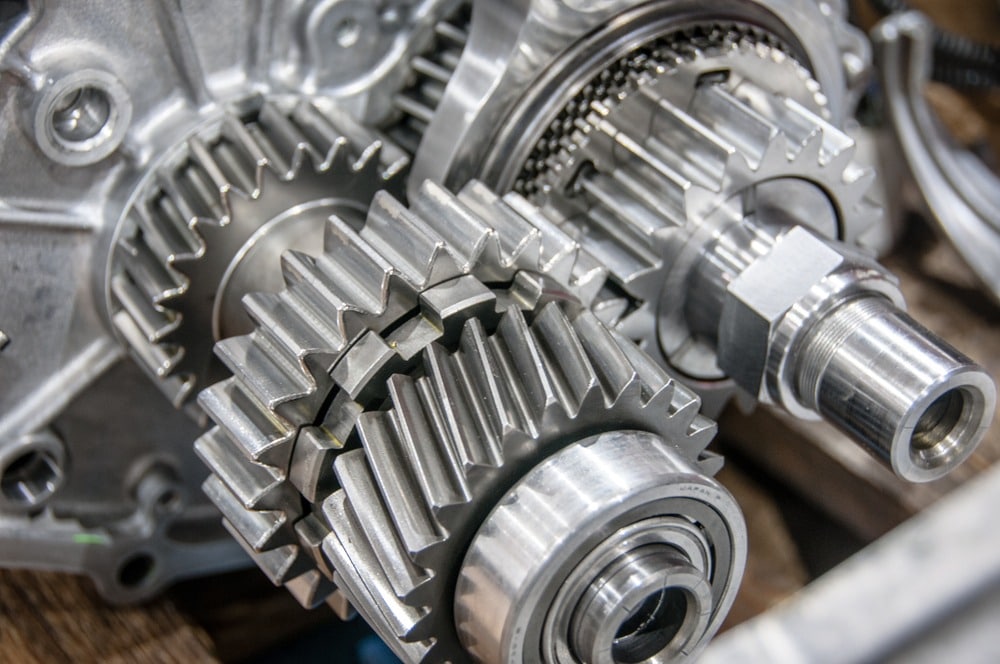

Mechanical transmission systems move power from engines or motors to wheels or other parts. Common types include gear drives, belt drives, chain drives, and hydraulic systems.

Gear Drives use gears like spur, helical, bevel, and worm. They offer high efficiency and precise speed control. They are common in cars and industrial gearboxes.

Belt Drives use rubber or polymer belts. V-belts and timing belts are popular. They are quiet, need little maintenance, and work well where some slip is acceptable.

Chain Drives use metal chains. They handle heavy loads and provide a positive, non-slip drive. You find them in motorcycles, bicycles, and conveyor systems.

Hydraulic Systems use fluid to transfer power. Torque converters and couplings allow for smooth acceleration. They are vital in construction equipment and automatic vehicles.

Choosing the right system depends on load, speed, environment, and cost.

Leading Companies Overview

The global mechanical transmission market is competitive. The top companies are known for their technical expertise and reliable products.

Bosch is a leader in automotive transmission systems. They develop advanced automatic transmissions and hybrid solutions for modern vehicles.

ZF Friedrichshafen specializes in driveline technology for cars and commercial trucks. Their 8-speed automatic transmission is an industry benchmark for efficiency.

Eaton is renowned for its heavy-duty truck transmissions and smart, connected drivetrains. They also supply systems for aerospace and vehicle applications.

Siemens provides integrated drive systems for industry. Their digital solutions and gear units optimize performance in manufacturing plants.

Sumitomo Heavy Industries manufactures high-precision gears and cycloidal reducers. Their products are essential in robotics and automated machinery.

SKF is famous for bearings but also offers complete transmission solutions. They are key suppliers to the wind power and industrial sectors.

Bonfiglioli excels in power transmission for renewable energy and agricultural equipment. They offer robust gearboxes that perform in tough conditions.

Other notable leaders include Brevini (winch drives and planetary gearboxes), Nidec (motor and drive systems), and Regal Rexnord (diverse industrial power transmission components).

Technology and Trends

The industry is evolving rapidly. Electrification is a major driver. Companies now develop compact reducers and e-drive units for electric vehicles.

Digitalization is another key trend. IoT sensors collect data from gearboxes. This data enables predictive maintenance. It prevents failures and reduces downtime.

New materials are also important. Companies use advanced composites and coatings. These materials reduce weight and friction. This improves energy efficiency and extends product life.

Automation demands high-precision components. Robotics and smart factories need accurate and reliable transmissions for precise movement.

Sustainability is a growing focus. Companies design systems for lower energy consumption. They also use recyclable materials to minimize environmental impact.

The future includes AI-optimized designs and adaptive systems that adjust to operating conditions in real-time.

Industry Applications

Mechanical transmission systems are vital across many sectors.

In the automotive industry, transmissions determine vehicle performance and fuel economy. Automatic and continuously variable transmissions (CVTs) are common.

Industrial manufacturing relies on gearboxes and drives. They power conveyor belts, machine tools, and packaging equipment. Reliability and precision are critical.

The energy sector uses heavy-duty gearboxes. Wind turbine gearboxes must handle massive loads and operate for decades with minimal maintenance.

In aerospace, transmission systems are used in landing gear and auxiliary power units. They must meet extreme safety and performance standards.

Agricultural machinery like tractors and combines operate in dirty, high-torque environments. Their transmissions are built for durability and power.

Even consumer products and robotics use small, efficient transmissions for automated functions and mobility.

Selection Guide and Best Practices

Choosing the right transmission supplier is crucial. You must evaluate several factors.

First, review technical specifications. Check torque capacity, speed ratios, efficiency ratings, and expected service life. Ensure they match your application needs.

Look for quality certifications. ISO 9001 certification shows a commitment to consistent quality and reliable manufacturing processes.

Consider customization. The best suppliers offer tailored solutions. They can modify standard products to fit your unique requirements.

evaluate global service and support. A strong supplier provides easy access to spare parts and technical assistance worldwide.

Analyze the total cost of ownership. The cheapest option may cost more long-term due to maintenance and energy use. Invest in efficiency and durability.

Finally, test the product. Request samples for real-world testing. Check customer references to verify performance claims.

Best practices include setting up a regular maintenance schedule and building a long-term partnership with your supplier for better support.