Top 10 Fertilizer Production Machinery Factories in China

China is the world's largest producer and consumer of fertilizer. The fertilizer machinery industry supports this massive agricultural demand. This equipment turns raw materials into usable granular or powdered fertilizer. The process includes crushing, mixing, granulating, drying, cooling, screening, and packaging. Modern agriculture needs efficient, eco-friendly, and smart machinery. This article provides a detailed look at China's top ten factories for this equipment.

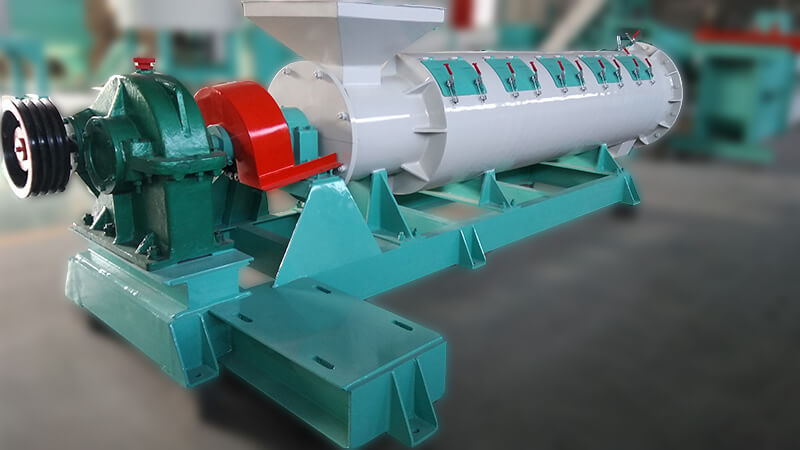

Understanding Fertilizer Production Machinery

It is important to know the types of machinery before choosing a factory. Different fertilizers need different machines. NPK compound fertilizer lines use batching systems, mixers, rotary drum granulators, dryers, and coolers. Organic fertilizer production requires compost turners, crushers, and packers. Biofertilizer production needs sterile tanks and special fermenters. Key innovations include energy-saving designs, automated PLC controls, and dust collection systems. The industry is moving toward smart IoT monitoring, modular lines, and green manufacturing with low emissions.

How We Ranked the Factories

We used clear and objective criteria to create this list. We looked at factory scale, measured by annual output and number of employees. We evaluated technological innovation by the number of patents held. Market share was assessed using export data and industry reports. We considered the range of products offered, from small organic lines to large compound fertilizer plants. After-sales service, proven client cases, and quality certifications like ISO 9001 were also key factors.

Top 3 Fertilizer Machinery Factories in China

Factory 1: This leader is known for its high-quality rotary drum granulators. Their machines achieve a granulation rate of over 95%. They use special wear-resistant materials for longer life. They offer custom production lines with an annual capacity from 50,000 to 300,000 tons. Their clients include major state-owned agricultural groups. Their equipment meets European CE standards.

Factory 2: This factory specializes in organic fertilizer machinery. Their hydraulic compost turner features intelligent temperature control. This technology shortens the fermentation cycle. They have a strong export presence in Southeast Asia. They provide excellent on-site installation guidance and training for clients.

Factory 3: This manufacturer is a pioneer in smart technology. Their production lines integrate SCADA systems for remote monitoring and diagnostics. Their core products include new vertical crushers and coolers. These machines are 20% more energy-efficient than traditional models.

Factories Ranked 4 to 6

Factory 4: This established factory focuses on cost-effective, small-scale production lines. Their flat die granulators are a popular choice for small to medium farms. They offer competitive pricing and emphasize simple maintenance. Their market is primarily in China's second and third-tier cities.

Factory 5: This expert in bio-organic fertilizer equipment provides sterile mixers and packing machines. Their innovation lies in using anti-corrosion materials and easy-to-clean designs. They have successful projects with biotechnology companies.

Factory 6: This export-oriented factory has a strong presence in the Middle East. Their dryer uses a hot air circulation system to reduce energy consumption. They hold several utility model patents. They have a local after-sales office in the region for fast spare part supply.

Factories Ranked 7 to 10

Factory 7: This newer factory offers modular design compound fertilizer lines. Clients can start small and expand capacity later. Their key products are efficient screening machines and coating drums. They are ideal for highly customized projects.

Factory 8: This factory stands out for its eco-friendly technology. Their equipment includes baghouse dust collectors and wastewater treatment systems. This ensures compliance with strict Chinese environmental regulations.

Factory 9: This provider offers a full one-stop solution from design to installation. Their product range covers both organic and compound fertilizer equipment. They are a smaller operation known for flexibility and quick response times.

Factory 10: This factory is known for its good value. They offer basic, reliable equipment like belt conveyors and packers at a lower cost. They are a solid choice for clients with a limited budget, and their machines meet essential quality standards.

How to Choose the Right Machinery Supplier

Selecting the best factory depends on your specific project needs. Follow these steps to make a smart decision.

First, define your production needs. Decide on your fertilizer type, target capacity, and budget.

Second, check for a technical match. Request parameter sheets for granulation rate, thermal efficiency, and other key metrics.

Third, verify factory credentials. Ask for certifications, visit the workshop if possible, and check client references.

Fourth, evaluate after-sales service. Ask about warranty terms, spare part availability, and training programs.

Fifth, analyze the total cost of ownership. Include the price of installation, energy use, and maintenance.

Sixth, request a equipment test or sample production run to check performance.

Seventh, negotiate the contract details. Be clear on delivery time, payment terms, and technical support.