Top 10 Conveying Equipment Factories in China

China is a global manufacturing leader. Its conveying equipment sector is a key part of this success. Conveying equipment moves materials, products, and components within facilities. It is essential for manufacturing, warehousing, and logistics. Chinese factories serve both domestic and international markets. They are known for high production capacity and innovation.

Industry Overview

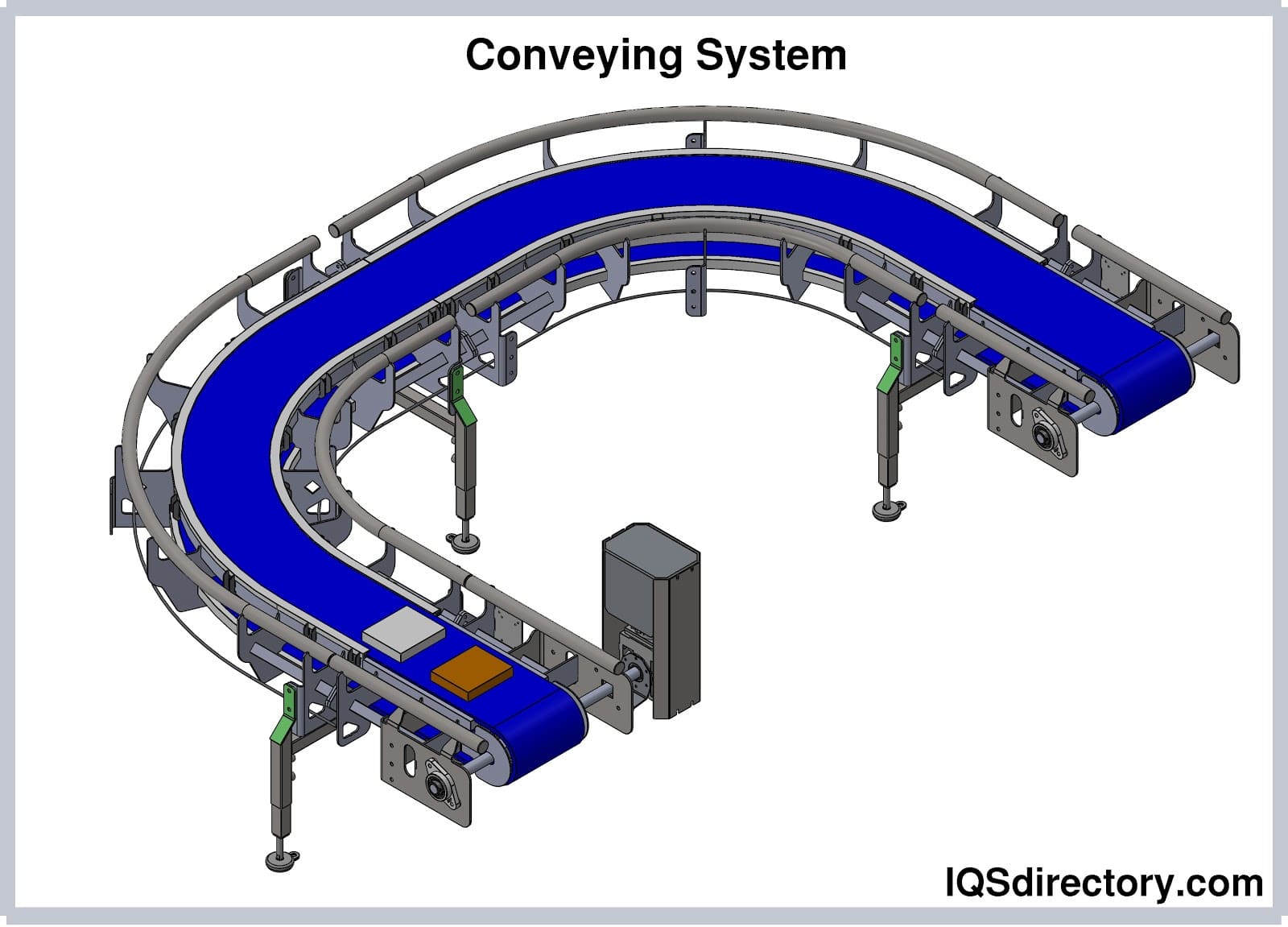

The conveying equipment industry in China is vast. It supports global supply chains across many sectors. These include mining, automotive, retail, and e-commerce. Common systems include belt conveyors, roller conveyors, chain conveyors, and bucket elevators. Growth is driven by e-commerce expansion, automation needs, and infrastructure development. China is also a major global exporter of this equipment. The China Heavy Machinery Industry Association (CHMIA) helps set industry standards.

Selection Criteria

We select factories based on specific criteria. This ensures a fair and accurate list. Key factors include:

- Annual production capacity and factory size.

- Investment in innovation and research & development (R&D).

- Quality certifications like ISO 9001.

- Market presence and client base, both domestic and international.

- Industry reputation and customer reviews.

- Range of products and ability to provide custom solutions.

Top 10 Conveying Equipment Factories

Here are ten leading factories in China for conveying equipment.

Shanghai Kaida Heavy Industry Group Co., Ltd.This factory is famous for large belt conveyors. They are used in mining and port operations. The company has a strong focus on heavy-duty applications.

Xinxiang Zhenying Mechanical Equipment Co., Ltd.They specialize in vibrating conveyors and feeders. Their equipment is known for efficiency and durability in material handling.

Northern Heavy Industries Group Co., Ltd. (NHI)NHI is a leader in heavy-duty conveyor systems. They serve the metallurgy and power generation industries with robust solutions.

Jiangsu Double Arrow Chain Transmission Co., Ltd.This company is a top manufacturer of conveyor chains and accessories. They supply components for various conveyor systems worldwide.

Huzhou Shuangli Automation Technology Equipment Co., Ltd.They focus on automated conveyor solutions. Their systems are integral to modern, smart warehouses and production lines.

Anhui Shengyun Heavy Machinery Manufacturing Co., Ltd.This factory produces conveyors for specialized applications. These include waste handling and power plants.

Huadi Heavy Industry Co., Ltd.They have strong expertise in bulk material handling systems. Their projects often involve large-scale industrial operations.

Sichuan Zigong Transportation Machinery Group Co., Ltd.This group is known for long-distance belt conveyor systems. They are experts in moving materials over extensive areas.

Other Notable FactoriesMany other factories also excel in this field. They produce high-quality roller conveyors and overhead chain systems. Their focus is on reliability and meeting international standards.

Technology and Automation

Leading factories integrate advanced technology into their products. The Internet of Things (IoT) enables smart conveyors for predictive maintenance. Artificial Intelligence (AI) optimizes material flow and saves energy. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are common in modern warehouses. Factories also design modular systems for flexible layouts. For sensitive industries, they develop sanitary conveyor designs.

Quality and Standards

Top factories follow strict quality assurance processes. They control quality from material sourcing to final assembly. Certifications like ISO 9001 for quality management are standard. Many also have ISO 45001 for workplace safety. For global market access, they obtain CE marking and other certifications. They use computerized simulations and prototype testing. Partnerships with research institutes ensure continuous improvement.

Sustainability Practices

Factories are committed to sustainable manufacturing. They use energy-efficient motors and Variable Frequency Drives (VFDs). This reduces power consumption. Many use recycled materials in their manufacturing processes. Products are designed for recycling or easy disassembly. Factories also work to reduce waste and emissions. Environmental management certifications like ISO 14001 are common goals.

Global Impact and Future

Chinese conveying equipment has a major global impact. Factories export to key international markets. Global initiatives like the Belt and Road create new opportunities. Industry trends include more demand for custom solutions. There is a shift towards service-oriented models, including remote monitoring. Challenges include global competition. Future trends involve deeper integration with Industry 4.0. New applications, like conveyors for additive manufacturing, are growing.