Top 10 Printing, Marking and Engraving Companies

The printing, marking, and engraving industry is a core part of modern manufacturing. These technologies are vital for industrial part tracking, product branding, and personalization. High-precision marking is now essential for quality control and supply chain management in the Industry 4.0 era.

Industry Standards and Certifications

Top companies follow strict global standards. The ISO 9001 certification ensures consistent quality in their equipment. For laser device safety, the IEC 60950 certification is critical. The CE mark is mandatory for selling products in Europe. In North America, the UL certification is a key standard. The FDA has specific rules for marking medical devices. The RoHS directive controls the use of hazardous materials. The aerospace industry requires the special AS9100 certification.

Advances in Laser Marking Technology

Fiber lasers offer high power for deep metal engraving. CO2 lasers work best on non-metal materials using thermal energy. UV lasers provide "cold" marks on sensitive parts like semiconductor wafers. Green lasers create precise marks on medical devices without heat damage. 3D dynamic focusing systems can mark on curved surfaces. Ultra-fast picosecond lasers are breaking new ground in machining brittle materials.

Key Technologies in Industrial Inkjet Systems

Continuous Inkjet (CIJ) systems are for high-speed production lines. Drop-On-Demand (DOD) printing is excellent for variable data. Thermal Inkjet (TIJ) handles porous materials well. Piezoelectric printers work with high-viscosity inks. UV-curable inks dry instantly upon exposure to light. Pigment-based inks offer superior outdoor durability. Advanced vision systems work with printers for closed-loop quality control.

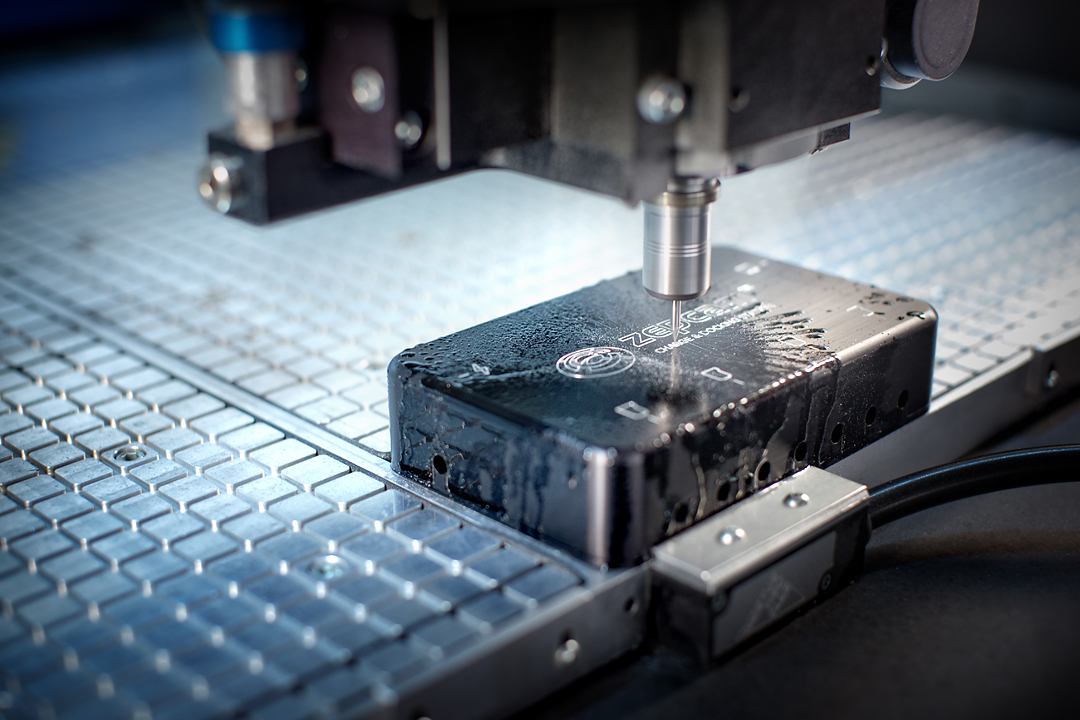

Innovations in Precision Engraving

Diamond drag engraving hardens the metal surface. Rotary engraving uses smart toolpath software for complex parts. Micro-milling creates fine details in mold steel with minimal tool wear. Electrochemical etching is used for biocompatible marks on medical implants. Ultrasonic machining precisely controls stress on glass. Nanoimprint lithography replicates tiny structures on optical devices. Hybrid processes combine methods for complex materials.

Deep Analysis of Industry Applications

Automotive parts need permanent VIN codes that survive corrosion tests. Electronic components require micro-codes that vision systems can read. Medical devices must have UDI codes that withstand sterilization. Aerospace part marks must resist high temperatures. Jewelry engraving balances artistic design with precision. Industrial tool marking needs extreme abrasion resistance. Food packaging uses inks that are safe for human consumption.

Service and Technical Support Systems

Leading firms offer 24/7 support with smart spare parts inventory. IoT-connected devices allow for remote diagnostics and early fault detection. Scheduled maintenance plans extend machine life. They provide standardized training and certification for operators. Companies maintain large databases of material settings for optimal results. Application labs offer sample testing with standardized procedures. Regular software updates ensure compatibility and access to new features.

Sustainability and Industry Trends

New energy-efficient lasers use less power than older models. Water-based inks reduce the emission of volatile organic compounds (VOCs). Modular machine design allows for better part reuse and repair. Inks are now made without lead or mercury for safer disposal. Cloud platforms help manage energy use across multiple machines. Digital workflows minimize material waste. The future points toward biodegradable inks for packaging.