Top 10 Actuators and Positioning Systems Factories in China

China is a global center for manufacturing actuators and positioning systems. These parts are vital for automation, robotics, and precision manufacturing. Actuators change energy into motion. Positioning systems place objects in space with high accuracy. The growth of this industry comes from technical progress, government support, and strong supply chains.

Industry Overview

The actuators and positioning systems industry in China is growing fast. Key drivers include more need for factory automation, the use of robots, and demands for precise manufacturing. Government plans like "Made in China 2025" help this growth. The supply chain is strong, from raw materials to final assembly. Many factories use ISO 9001 standards for quality. There is also a rising demand for energy-saving and smart actuators.

Standards for Top Factories

We choose top factories based on strict standards. Production capacity means making large volumes without losing quality. Technical innovation includes research and new patents. Certifications like ISO 14001 show care for the environment. A diverse customer base proves global acceptance. Industry reputation comes from awards and peer respect. Customization means meeting special client needs. After-sales support includes maintenance and technical help.

Factory 1: Linear Actuator Specialist

This factory focuses on electric linear actuators. They are known for high precision and long life. Their key products work in industrial automation. They use smart controls for real-time monitoring. Their assembly lines are automated for efficiency. They test each product for durability. They serve the automotive and aerospace sectors. They use energy-efficient motors for sustainability.

Factory 2: Innovation in Rotary Actuators

This leader makes high-torque rotary actuators for robotics. Their research develops AI for predictive maintenance. They use advanced CNC machines for precision parts. They have CE and UL safety certifications. They work with major European manufacturers. They offer custom mounts and seals. They have won awards for innovative design. They export to North America and Asia.

Factory 3: Quality for Medical Devices

This factory is famous for quality. They make precision positioning systems for medical equipment. Their products offer sub-micron accuracy and quiet operation. They calibrate every unit thoroughly. They build products in clean rooms to avoid contamination. They use piezoelectric motor technology for ultra-precise movement. They provide application engineering support. They meet FDA standards for medical devices. They use waste-reduction practices.

Factory 4: Custom Actuator Solutions

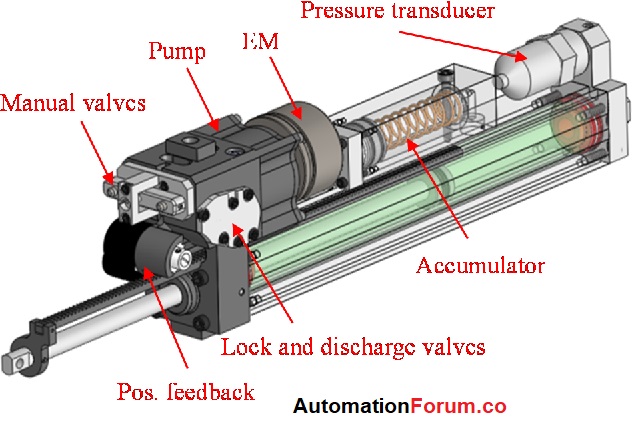

This factory creates custom solutions for unique needs. They engineer and prototype in-house. Their key products include hydraulic actuators for heavy machinery. They can handle small production runs. They use materials like stainless steel and titanium for tough conditions. They work closely with clients from idea to product. They have ATEX certification for explosive environments. They make custom solutions for the oil and gas industry.

Factory 5: Advanced Linear Stages

This technical factory makes linear stages for semiconductor manufacturing. They use direct-drive technology for high speed and smooth motion. They work with universities on material science research. Robots help with assembly in their factory. They use laser interferometers to check product quality. Their systems work in electronics and photonics. They offer custom software for control. They use energy-efficient production methods.

Factory 6: Global Reach

This factory exports to over 50 countries. Their key products are electric cylinders for packaging. They control everything from casting to assembly. Their distribution network ensures on-time delivery worldwide. They offer technical support in many languages. They meet RoHS standards for environmental safety. Customer stories show how they improve efficiency. They focus on markets in emerging economies.

Factory 7: Cost-Effective Production

This factory offers good quality at competitive prices. They use lean manufacturing to optimize production. Their main products are standard linear actuators for general use. They manage their supply chain to keep material costs low. They use value engineering to cut cost without losing performance. Customers see a quick return on investment. They are in high demand in price-sensitive markets. They use statistical process control for quality.

Factory 8: Sustainable Manufacturing

This factory focuses on being green. They make energy-efficient actuators with regenerative braking. Their facility uses solar power. They prefer recycled and biodegradable materials. They have ISO 50001 certification for energy management. Their initiatives include water recycling and cutting carbon emissions. They teach customers about saving energy. They partner with environmental groups.

Factory 9: Focus on Research and Development

Research is central to this factory. They work on next-generation positioning systems. Their innovations include adaptive control for nano-positioning. Their labs have advanced simulation and testing tools. They collaborate with research institutes. They hold patents for smart actuators that self-calibrate. They publish technical papers. They work with clients on joint development. Future plans include integration with quantum sensors.

Factory 10: Customer-Centered Approach

This factory is known for excellent service. Their key products are precision stages for lab automation. They work closely with clients through feedback and consulting. Their services include installation, training, and maintenance. They offer 24/7 technical support. They have a high customer retention rate. Case studies show how they solve tough problems. They use customer feedback to keep improving.

Future Trends

The future includes smart, connected devices. Technology will integrate IoT for real-time data and monitoring. AI and machine learning will allow predictive maintenance. Industry 4.0 will increase demand for cyber-physical systems. Sustainability will focus on energy savings and eco-friendly materials. New applications in biotech and renewable energy will create opportunities. Global cooperation will boost innovation. Challenges include keeping up with fast technology changes and global competition.