Top 10 Slaughtering Equipment Manufacturers and Companies

Slaughtering equipment is a core part of the modern meat processing industry. This equipment handles animals in a way that is efficient, humane, and meets strict hygiene standards. The range of tools includes everything from stunning devices to cutting machinery. This equipment is vital for ensuring food safety and operational efficiency. As global meat consumption grows, manufacturers are key to meeting high regulatory standards and boosting production capacity.

Types of Slaughtering Equipment and Key Terms

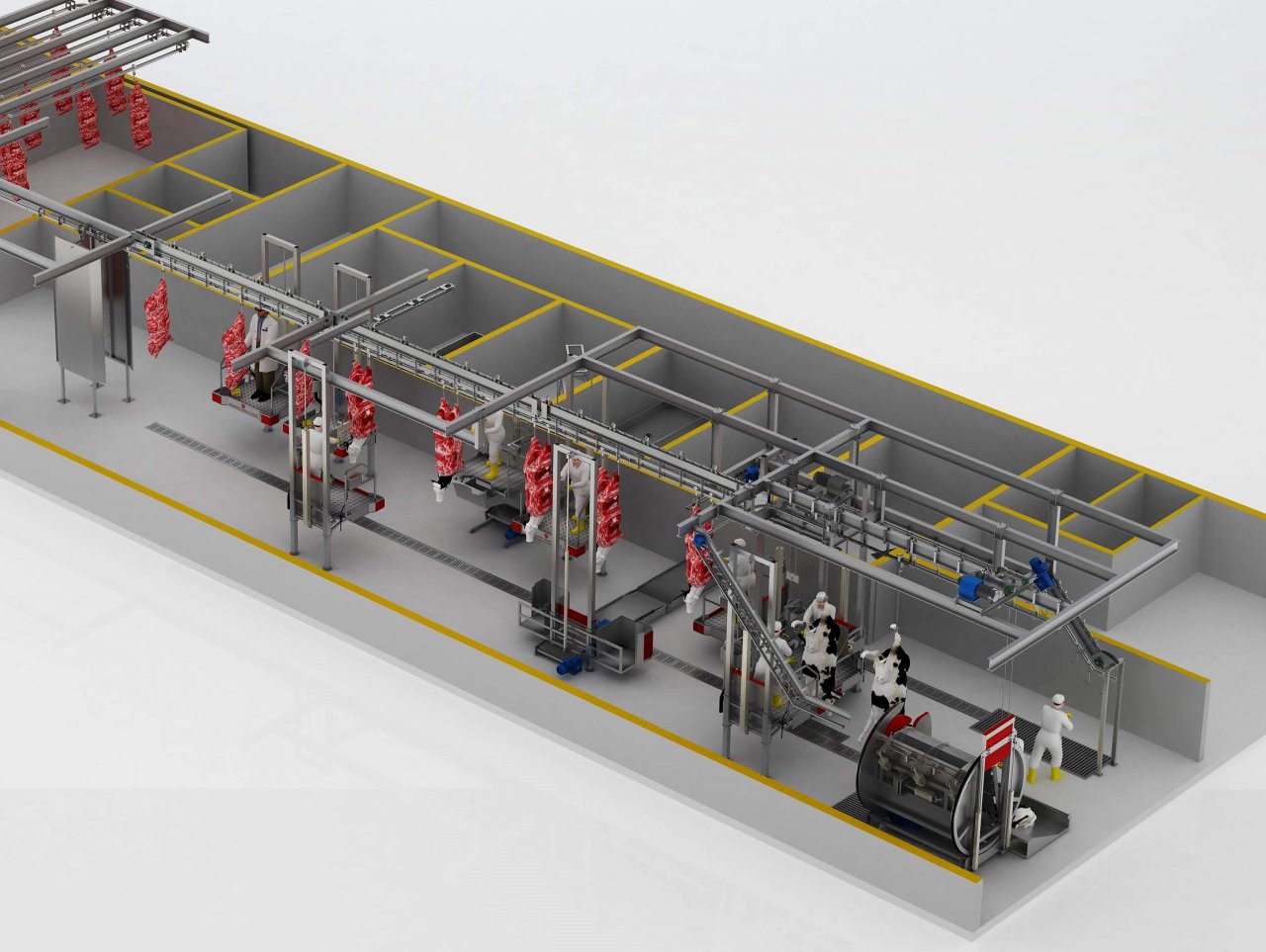

Understanding the different machines used in processing is essential. Stunning equipment, like electrical stunners and pneumatic guns, ensures humane handling. Bleeding and hanging systems, such as bleeding rails and overhead conveyors, manage blood collection and hygiene. Dehairing or skinning machines, including scald tanks and debairers, are used for livestock and poultry. Evisceration tools, like automatic opening machines and gut tables, improve efficiency and safety. Finally, cutting and boning equipment, such as band saws and automated cutting systems, process the carcass.

Key industry terms provide important context. Carcass handling refers to moving the animal body after slaughter. HACCP compliance means the equipment meets Hazard Analysis Critical Control Point food safety plans. Automated grading uses technology to sort carcasses by quality.

How Industry Standards and Regulations Shape Equipment

Global regulations directly influence equipment design. Rules like the EU's EC No 853/2004 and U.S. FSIS guidelines require easy-to-clean surfaces and corrosion-resistant materials. Animal welfare standards, such as OIE guidelines, push innovation in stunning and handling tools. Environmental laws lead to designs with water recycling and waste treatment systems. Energy efficiency standards also drive manufacturers to create low-power consumption equipment.

An Overview of Leading Slaughter Equipment Manufacturers

The global market features several key players known for quality and innovation.

Marel (Iceland) is a leader in integrated solutions and high automation for all meat types.

BAADER (Germany) focuses on precision cutting equipment for poultry and fish processing.

Bettcher Industries (U.S.) is renowned for its pneumatic tools and advanced deboning machines.

Cantrell (U.S.) provides customized slaughter line solutions for various processing needs.

CTB Inc. (U.S.) specializes in comprehensive poultry processing systems.

SFS (Germany) is a prominent name in automation for food processing lines.

Prime Equipment Group (U.S.) is known for building durable and highly efficient equipment.

DURAND (France) focuses on automation technology for slaughter lines.

Innovation and Technology Trends

The industry is rapidly adopting new technologies. Automation is a major trend, with robots performing precise cuts and reducing manual labor. The Internet of Things (IoT) allows for real-time monitoring of machine performance and maintenance needs. For hygiene, innovations include antimicrobial coatings and Clean-in-Place (CIP) systems. Data analytics and AI are now used to optimize processes, like using vision systems for automatic carcass grading. Sustainability is also key, with new equipment featuring energy recovery systems and designs that reduce water usage.

Key Factors for Choosing Slaughter Equipment

Selecting the right equipment requires careful thought. You must match the machine's capacity to your processing volume, measured in units per hour. Hygiene and compliance are non-negotiable; equipment must meet FDA, USDA, or EU standards and use materials like 304 or 316 stainless steel. Assess durability, maintenance needs, and the availability of spare parts. Consider if the equipment is flexible enough for different animal types. A full cost analysis includes the initial investment, operating costs, and potential return on investment (ROI). Safety features like emergency stop buttons and guards are critical. Finally, always check the supplier’s reputation through customer reviews and industry certifications.