Top 10 Hydraulic and Pneumatic Actuators Manufacturers

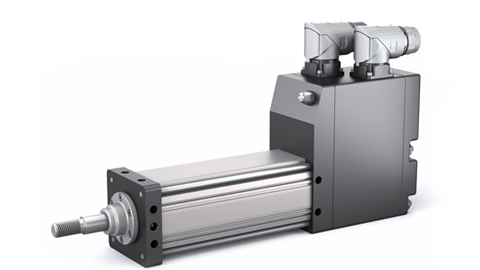

Hydraulic and pneumatic actuators are core components in modern industrial automation. They convert fluid power into precise mechanical motion. Hydraulic actuators use incompressible fluid to generate high force. Pneumatic actuators use compressed air for fast cycling. These devices power everything from heavy machinery to precision manufacturing.

Technical Standards and evaluation framework

We use clear metrics to evaluate manufacturers. Force output is a key measure. Hydraulic actuators range from 0.1 to 10,000 kN. Pneumatic actuators go up to 500 kN. Response time is also critical. Pneumatic systems respond in under 100 milliseconds. Hydraulic systems respond in 50 to 200 milliseconds. Precision is vital. Many actuators offer repeatability within ±0.1mm.

International standards ensure quality. ISO 4413 covers hydraulic systems. ISO 4414 covers pneumatic systems. Material science drives progress. Chrome-plated piston rods resist corrosion. Carbon fiber composites reduce weight. Energy efficiency is a major focus. Hydraulic variable pumps save 30% energy. Pneumatic vortex tube cooling improves performance.

Top Hydraulic Actuator Manufacturers

Bosch Rexroth leads with robust designs. Their RC series hydraulic cylinders use a C4 anti-corrosion coating. They operate at pressures up to 350 bar. Parker Hannifin integrates smart technology. Their PVplus piston pumps have built-in sensors. These sensors enable predictive maintenance.

Eaton improves power density. Their Char-Lynn motors use a patented gerotor design. This increases torque density by 25%. Kawasaki Heavy Industries focuses on noise control. Their K3VL axial piston pumps operate below 70 dB(A). Danfoss supports connectivity. Their Plus+1® controllers work with IoT protocols.

Nachi delivers high precision. Their hydraulic servo systems achieve positioning within ±0.01mm. Moog offers high-speed control. Their G631 series servo valves have a frequency response over 200 Hz.

Leading Pneumatic Actuator Innovators

Festo sets the standard for durability. Their DSBC cylinders include magnetic coupling indicators. They last for over 50 million cycles. SMC emphasizes ease of use. Their CJ2 series uses a modular design. This reduces installation time by 40%.

Norgren solves leakage problems. Their rodless cylinders use a unique magnetic gap technology. This ensures zero leakage. Airtac follows international standards. Their ISO 15552 cylinders have bore sizes from 8mm to 320mm. They operate from -20°C to 80°C.

Camozzi reduces weight. Their P1 series uses polyamide bodies. This cuts weight by 60%. CKD ensures rapid response. Their AB41 solenoid valves activate in 10 ms. They also have an IP67 protection rating.

Application Scenarios and Industry Solutions

Automotive manufacturing requires high force. Multi-stage hydraulic cylinders provide 6,000 kN for stamping presses. Food packaging needs clean designs. Stainless steel pneumatic actuators meet FDA standards. They withstand high-pressure washdowns.

Aerospace demands precision. Electro-hydraulic servo actuators control flight surfaces. They achieve accuracy within 0.05 degrees. Energy sector tools are powerful. Hydraulic splitters from Parker generate 250 MPa for mining.

Semiconductor manufacturing requires cleanrooms. Pneumatic robots from SMC meet Class 1 standards. Medical devices use biomimicry. Festo's pneumatic artificial muscles mimic human movement with 95% accuracy.

Market Trends and Future Technology Roadmap

Smart actuators are the future. They integrate pressure and temperature sensors. Bosch's IoT Hydraulics is one example. Energy efficiency is a priority. Hydraulic hybrid systems recover braking energy. Eaton's XD lineup is a leader here.

New materials extend life. Graphene seals can last three times longer. Digital twins speed up development. Virtual commissioning cuts deployment time by 30%. 5G enables remote control. Norgren's Pneumatic Cloud uses 5G for under 5ms latency.

Eco-friendly fluids are gaining ground. Danfoss offers biodegradable hydraulic oil. Oil-free pneumatic systems are also becoming standard.

Selection Guide and Compliance Considerations

Analyze your load curve. Shock loads need hydraulic cushioning. Consider your environment. Marine applications require 316L stainless steel. Certifications ensure safety. Look for ATEX防爆 certification for Group IIB environments. ISO 13849 defines safety levels.

Calculate total lifecycle cost. Energy use is a major factor. In pneumatic systems, energy can be 60% of the total cost. Check supply chain reliability. European brands often have 12-week lead times. Asian brands can deliver in 4 weeks.

evaluate after-sales support. Parker's GlobalStar system offers wide remote diagnostics. Check custom options. Many makers offer non-standard strokes with ±0.5mm tolerance.