Top 10 Auto Body Shop Equipment Companies

Auto body shop equipment is the foundation of collision repair and body shop operations. It allows technicians to perform tasks from minor dent removal to major collision rebuilding. This equipment ranges from basic hand tools to advanced computerized systems. Each piece plays a key role in the vehicle restoration process. Investing in high-quality equipment improves repair quality. It also significantly increases shop efficiency, technician safety, and overall profitability. This guide explores top equipment manufacturers with a focus on innovation, reliability, and industry-specific solutions.

Defining Auto Body Shop Equipment Categories

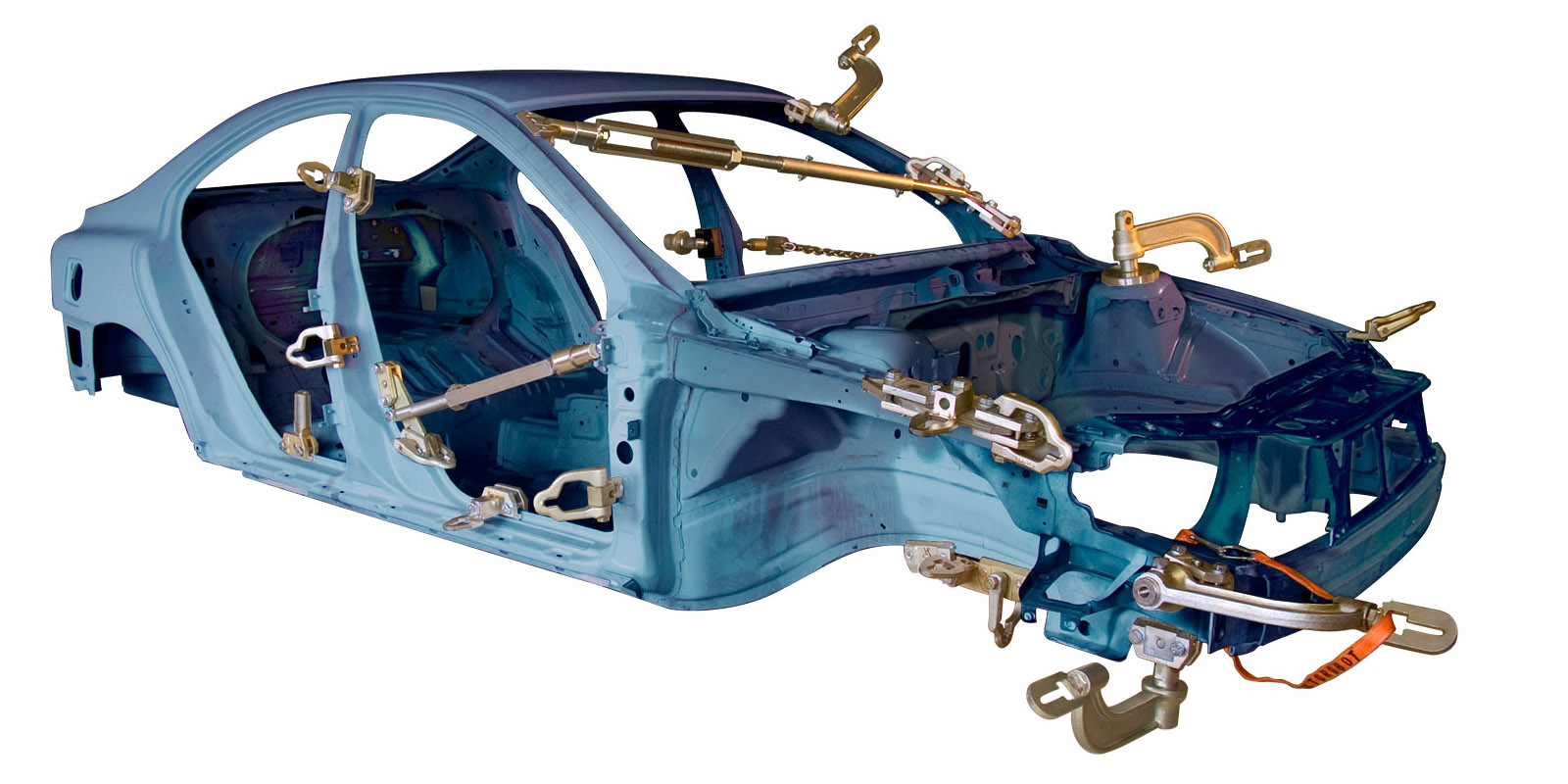

Auto body equipment falls into several core categories. frame correction systems use hydraulic power to pull damaged frames and body structures back to specification. They often include laser measuring systems for precision. Spray equipment includes HVLP (High Volume Low Pressure) spray guns, paint booths, and preparation stations. These are designed for dust-free environments and even paint application. Diagnostic and measurement tools use ultrasound or infrared technology to assess structural damage. Wheel alignment equipment ensures proper vehicle alignment. Sheet metal tools include power hammers, pulling systems, and specialized clamps for shaping metal.

Key Criteria for evaluating Equipment

Several factors are critical when choosing body shop equipment. Precision is vital; frame machine measurement systems must be accurate to the millimeter for safety-critical repairs. Assess durability through heavy-duty steel construction and industrial-grade components. Technical integration includes software compatibility with vehicle-specific databases for OEM repair procedures. Ergonomic design reduces technician fatigue with features like adjustable stands. Safety features include emergency stop buttons and OSHA compliance. Always evaluate the supplier's support, training availability, warranty terms, and local service technicians. Conduct a cost-benefit analysis that weighs the initial investment against long-term operational savings.

Top Industrial-Grade Equipment Manufacturers

Industrial-grade manufacturers set the standard for professional shops. Car-O-Liner from Sweden provides frame equipment with its VisionTec AR system. This uses augmented reality overlays to guide repairs. Chief Automotive Technologies in the USA is known for its Krone series lifts and Uni-body clamping systems. They offer superior stability for vehicles during repair. SATA from Germany leads in spray equipment. Their spray guns, like the SATA 5000, provide precise paint control. Spies Hecker, part of BASF, offers water-based paint systems that meet strict environmental regulations. CarBench from Italy specializes in modular repair workstations for custom solutions.

Specialized and Niche Equipment Innovators

Some manufacturers focus on solving specific repair challenges. ProSpot in the USA specializes in resistance spot welders. Their equipment offers welding control that matches OEM processes. Spiram from France provides electrostatic adhesion pulling systems for dent repair. This method requires no drilling. Nussbaum from Germany develops advanced measurement technology for hybrid material vehicles. This includes tools for aluminum and carbon fiber. Tecna from Italy innovates in spray solutions with energy-efficient paint booths that feature heat recovery systems. These companies address the complexities of modern vehicle construction.

Cost-Effective and Mid-Range Solutions

Mid-range manufacturers balance professional features with accessibility. Blackhawk in the USA offers reliable frame equipment like the Blackhawk Eclipse. It comes with user-friendly software. Global Finishing Solutions (GFS) provides affordable paint booths with good airflow control. Ammco is a standout in wheel service equipment with dependable alignment machines. These brands are ideal for growing shops. They often provide rental or financing options. The equipment is typically designed for easy maintenance with widely available spare parts.

Emerging Technologies and Industry Trends

The industry is evolving with new technologies. There is growing demand for Electric Vehicle (EV) specific equipment. This includes insulated tools and safety gear for high-voltage systems. Automation is becoming more common with paint spraying robots. Companies like ABB offer integrated systems that improve consistency. Sustainability drives the development of water-borne paint equipment and VOC (Volatile Organic Compound) reduction systems. IoT (Internet of Things) integration allows for remote monitoring of equipment performance and predictive maintenance. Repairing lightweight materials like aluminum requires specialized tools, including compatible welders and pulling systems.

Practical Tips for Selecting and Maintaining Equipment

Follow these practical steps for your shop. First, conduct a facility assessment. Check for space limitations and power requirements, such as three-phase power. Prioritize equipment that is compatible with your existing workflow and technician skill level. Implement a regular maintenance schedule. This includes filter changes for paint booths and calibration checks for frame machines. Build a relationship with suppliers who offer comprehensive training. This ensures correct equipment use. Consider scalability; choose systems that can expand modularly as your business grows. Investing in quality tools usually provides a better return on investment by reducing rework and increasing throughput.