Introduction

This article provides an in-depth exploration of metal plating types.

It covers detailed information on topics including:

- Principles of metal Plating

- Types of metal Plating based on Materials

- Applications and Advantages of metal Plating

- And More...

Chapter 1: Understanding metal Plating Fundamentals

This chapter introduces metal plating, explaining its definition, various techniques, and the materials used in these processes.

metal Plating Defined

metal plating involves applying a metallic layer onto a metal object's surface or substrate. Techniques include electroplating, where metal ions deposit using electric current.

Electroless plating deposits metal ions without electrodes, enhancing corrosion resistance with unique advantages for each method.

Beyond environmental protection, plating improves aesthetics. Coatings are categorized as industrial or commercial.

Commercial decorative coatings enhance appearance and durability for everyday items like tools and jewelry. Industrial coatings strengthen components for harsh environments, improving machinery durability.

These coatings improve solderability, increase strength, reduce friction, and may alter electrical conductivity. They also prepare surfaces for painting and enhance magnetic properties.

metal Plating Processes

Key metal plating processes include:

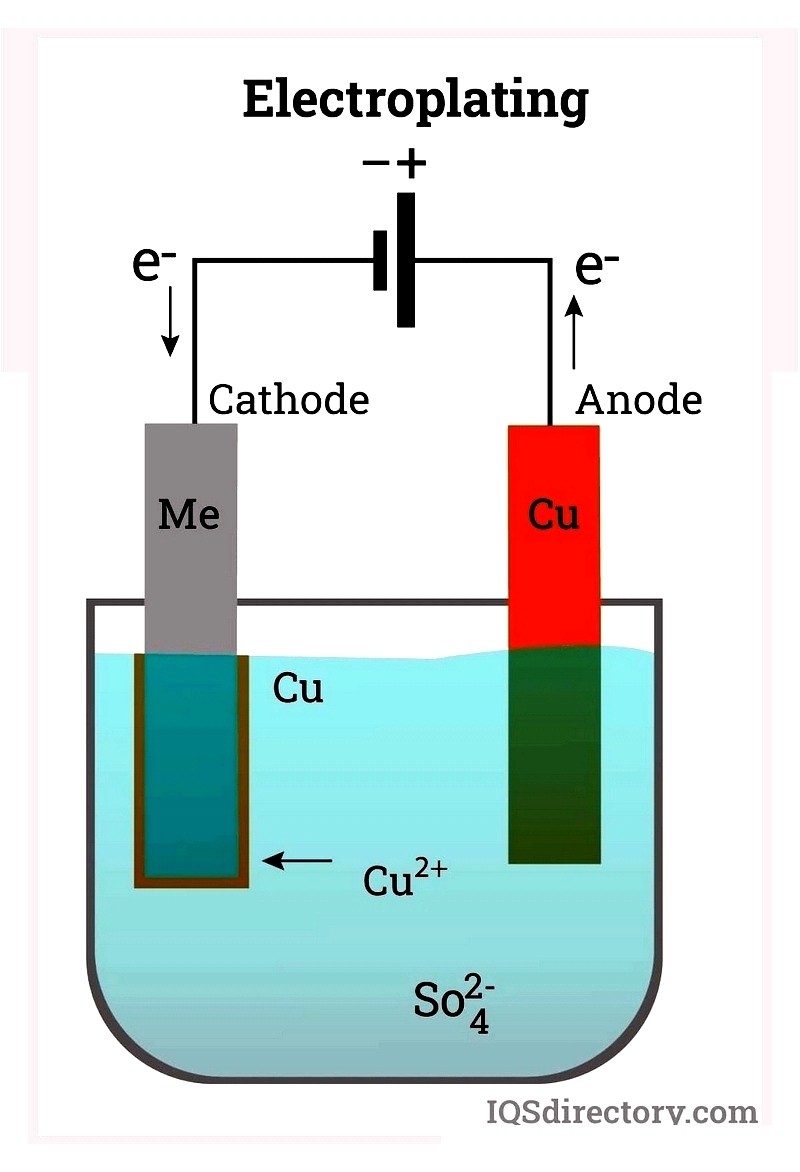

Electroplating

Electroplating uses electrodeposition to coat workpieces. Through electrolysis, metal transfers from anode to cathode in an electrolyte solution with electric current.

Current drives ions to create uniform metal layers, typically copper or nickel. While mainly for metals, special methods enable plating on certain plastics.

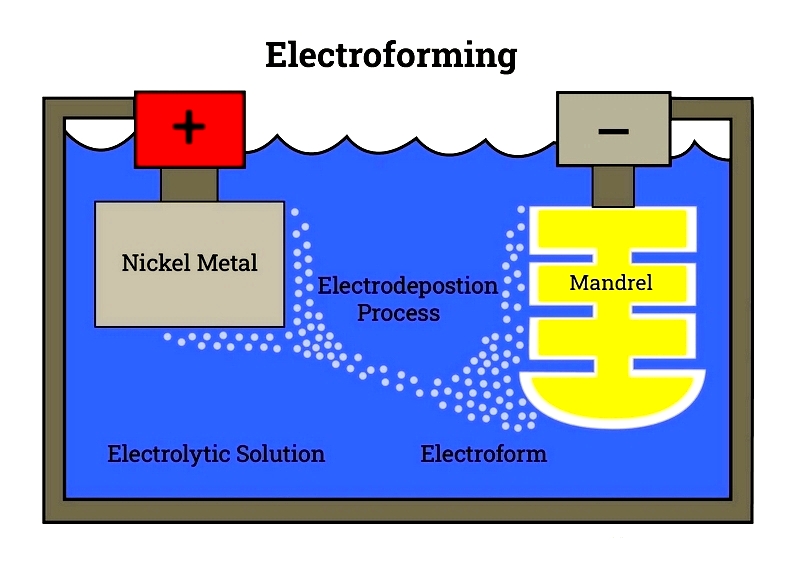

Electroplating vs Electroforming

Both use electrodeposition, but electroforming requires removable molds to create standalone metal parts.

Electroplating coats existing items, while electroforming creates new metal components.

Common Electroplating Materials

Various metals are used alone or combined, including:

- Brass

- Cadmium

- Chromium

- Copper

- Gold

- Iron

- Nickel

- Silver

- Titanium

- Zinc

Substrates range from metals to plastics, with non-conductive materials requiring conductive pretreatment.

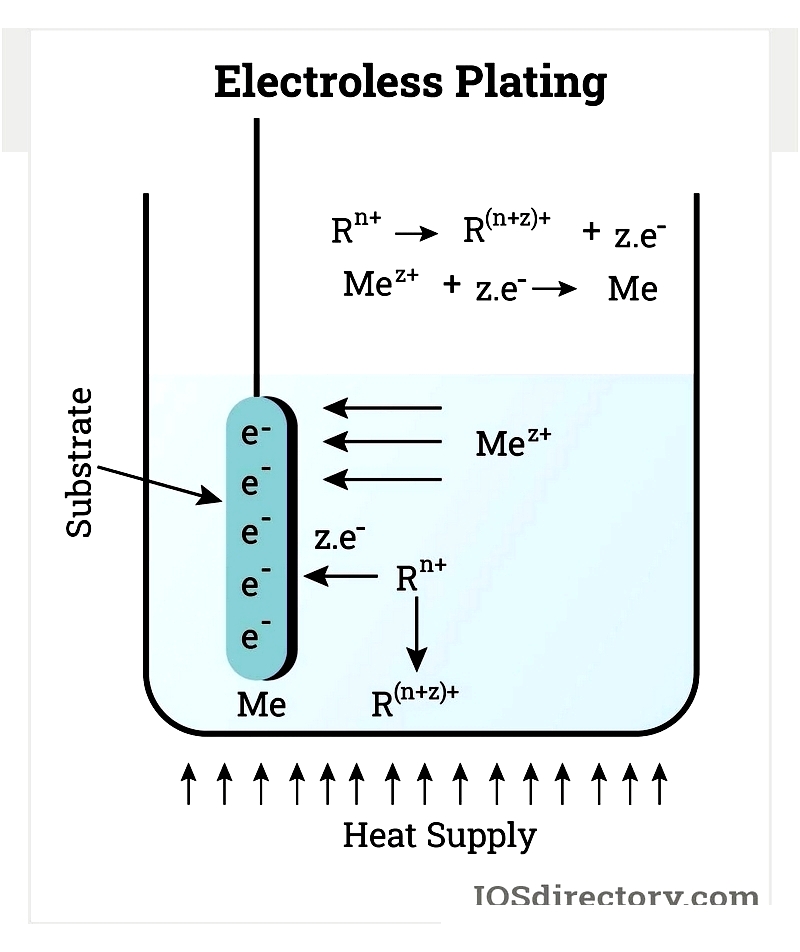

Electroless Plating

This chemical method deposits metal without electricity, using reducing agents and catalysts. It's ideal for plastics in printed electronics.

Unlike electroplating, chemical reactions deposit metal uniformly, even on complex shapes. Sodium hypophosphite commonly serves as the reducing agent.

Also called auto-catalytic plating, it prepares non-conductive surfaces for electroplating or conductive applications.

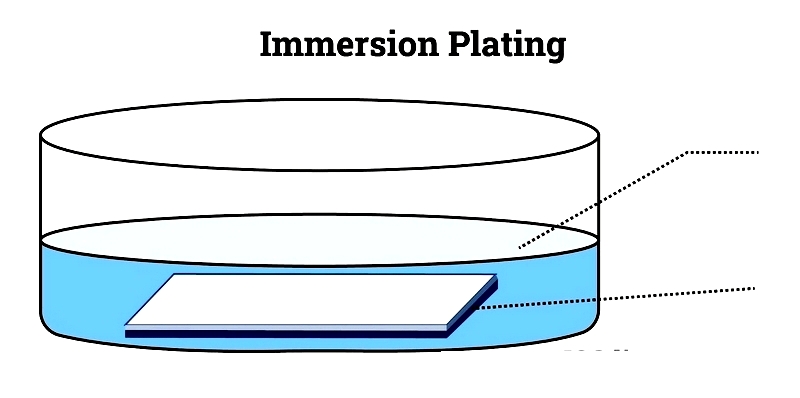

Immersion Plating

This process dips base metal into noble metal solutions, creating replacement reactions that deposit coatings.

Used to enhance electrical properties and adhesion, deposition stops when fully covered. Temperature varies by metal type.

Electroplating vs Electroless Comparison

Both improve strength and corrosion resistance but differ in current use. Electroplating requires complex equipment while electroless plating offers simpler, safer processing.

Electroless nickel plating avoids electrical hazards and produces corrosion-resistant components without complex systems.

Chapter 2: metal Plating Types by Material

This chapter examines plating techniques by metal type, detailing properties, applications, benefits, and limitations across industries.

Electroless Nickel Plating

This technique applies uniform nickel-phosphorus coatings without electricity, ensuring complete coverage on complex parts.

The process involves:

- Pre-Treatment: Thorough cleaning removes contaminants

- Surface Preparation: Acid activation enables deposition

- Deposition: Autocatalytic reaction creates durable layers

- Post-Treatment: Heat treatment enhances hardness

Coating Thickness

Deposition rates range 5-25 microns/hour, with five standard grades for different applications like PCBs and hydraulics.

Zinc Plating

This cost-effective corrosion protection for steel/iron includes:

- Electroplating: Precise zinc application

- Sherardizing: Heat with zinc dust

- Hot-Dip: Molten zinc immersion

- Spray Coating: For large components

Cadmium Plating

Offers marine/aerospace corrosion protection, though regulations favor alternatives like zinc-nickel.

Chrome Plating

Provides decorative shine and industrial durability, with trivalent chromium gaining popularity as safer alternative.

Aluminum Plating

Valued for lightweight corrosion protection in electronics and aerospace, though oxide layers challenge adhesion.

Aluminum Plating Methods

Zincation pretreatment enables successful plating for connectors and EMI shielding.

Common Aluminum Platings

- Tin: For electronics conductivity

- Nickel: Enhances hardness

- Silver/Gold: For high-performance applications

- Electroless Nickel: Foundation layer

Copper Plating

Essential for electronics conductivity, with acid, alkaline, and mild alkaline bath options.