Introduction

This article provides comprehensive knowledge about forging.

You'll explore various topics including:

- The definition of forging

- Key steps in the forging process

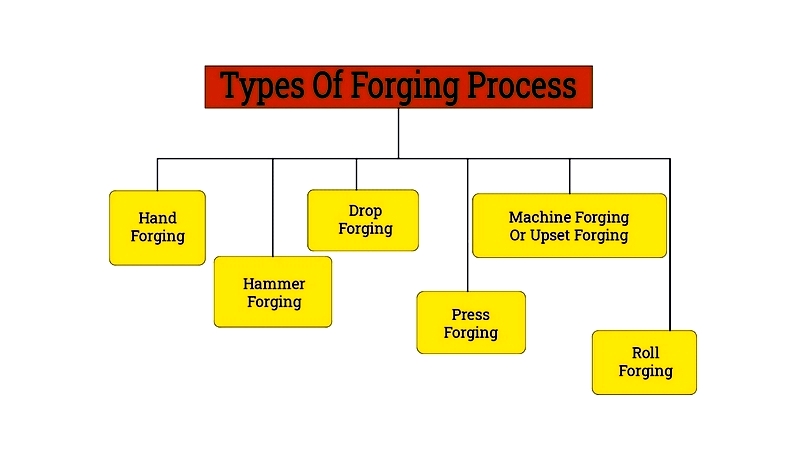

- Various forging techniques

- Common forged metals

- And additional valuable information

Chapter One – Understanding Forging

Forging is a metal shaping process that involves reshaping, deforming, and compressing metal to achieve specific designs. This can be performed through either hot or cold methods, depending on the metal type and design requirements.

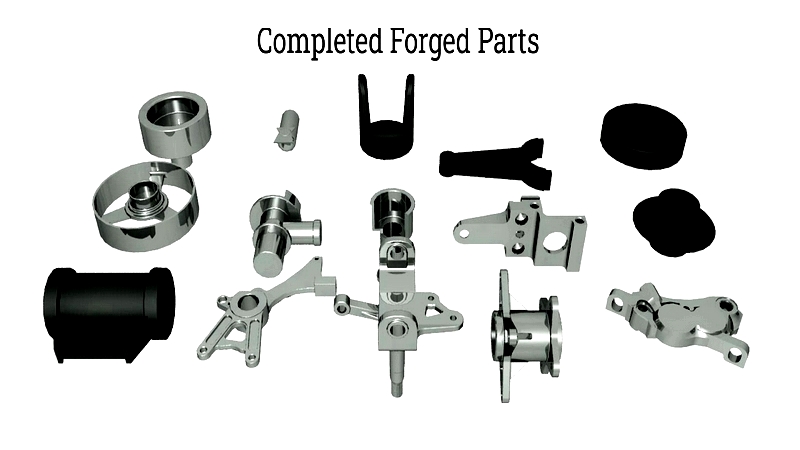

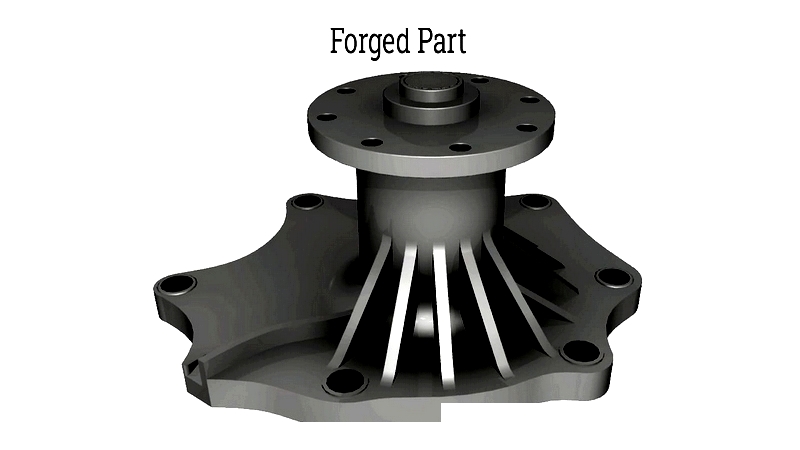

Modern machinery and equipment extensively incorporate forged components. From tools to automotive parts, forged elements are found in numerous products. Despite its ancient origins, forging remains fundamental to contemporary metalworking and manufacturing.

Chapter Two – The Forging Process Steps

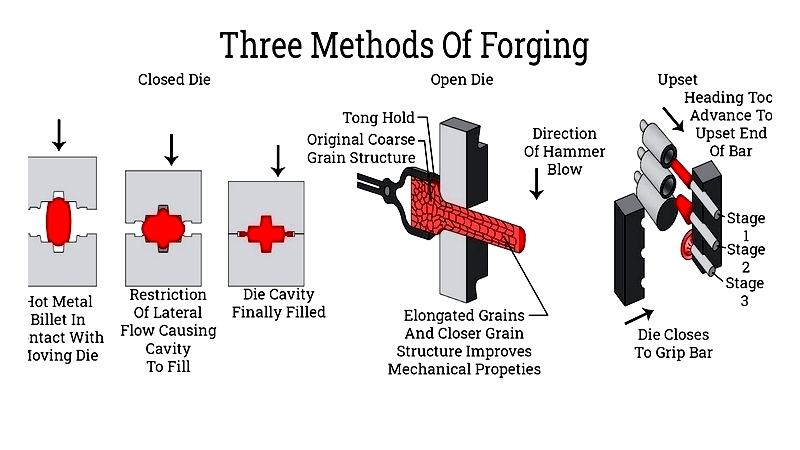

Forging has served as a crucial metalworking technique for millennia. As a cornerstone of modern manufacturing, it contributes significantly to industries like automotive, aerospace, and construction. While technological advancements have refined forging methods, the core principles persist. Whether using open-die, closed-die, or other forging techniques, the goal remains precise metal shaping through controlled force application. The specific steps may vary by technique and material, but share fundamental similarities.

Essential Forging Steps

Selecting metals for Forging

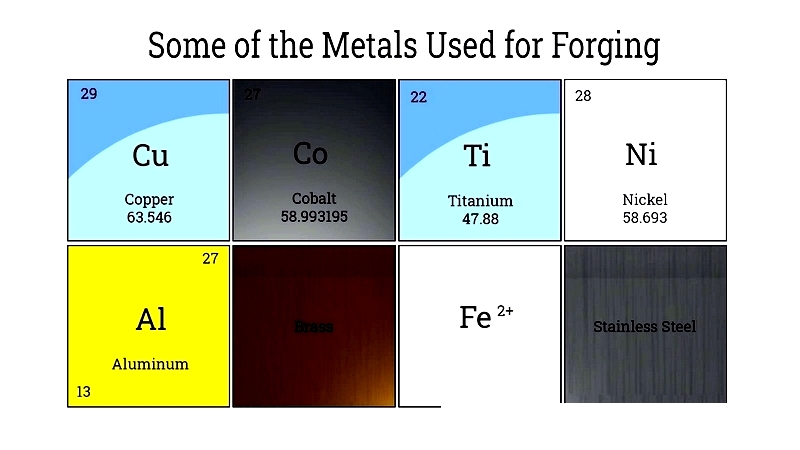

The forging method depends largely on the metal's characteristics. Different metals possess unique properties like hardness, strength, and corrosion resistance that influence the forging approach. Virtually all metals can be forged with appropriate techniques.

Common forged metals include carbon steel, stainless steel, aluminum, and titanium. Material selection depends on the final product's requirements. For instance, aerospace components often use titanium for its strength-to-weight ratio, while carbon steel suits automotive applications. Understanding these properties ensures high-quality forged products.

Forging Techniques and Operations

The specific forging operations depend on the metal type and desired characteristics. Harder metals typically require hot forging, while softer metals like aluminum may use cold forging. Hot forging heats metal above its recrystallization point for easier shaping, while cold forging occurs at room temperature for better surface finish. Both methods use specialized equipment to apply precise force, ensuring optimal metal flow and structural integrity.

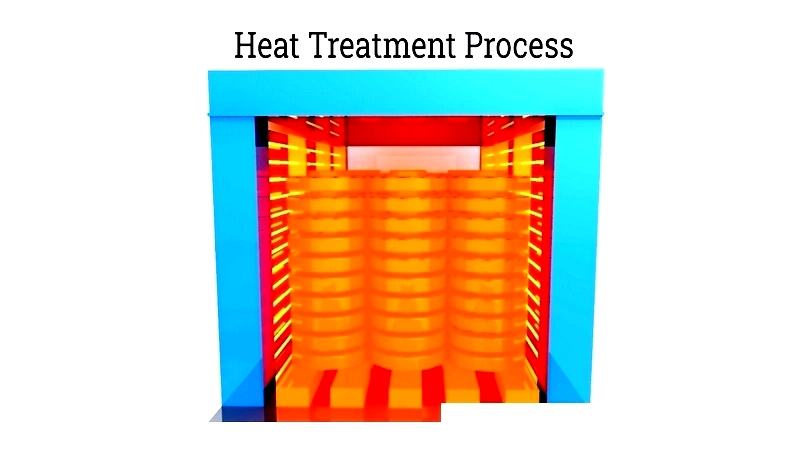

Annealing and Heat Treatment

Annealing modifies metal properties to enhance workability. This process heats metal above its recrystallization temperature, then controls cooling to improve ductility and reduce hardness. While primarily used in hot forging, annealing also benefits certain cold forging applications. Additional heat treatments like quenching may follow forging to optimize performance for specific uses.

metal Shaping Process

once prepared, the metal undergoes shaping through various techniques like hammering or compressing. This stage may involve multiple passes through custom dies to achieve precise dimensions. Regardless of method, careful deformation ensures accurate formation of critical features while minimizing material waste.

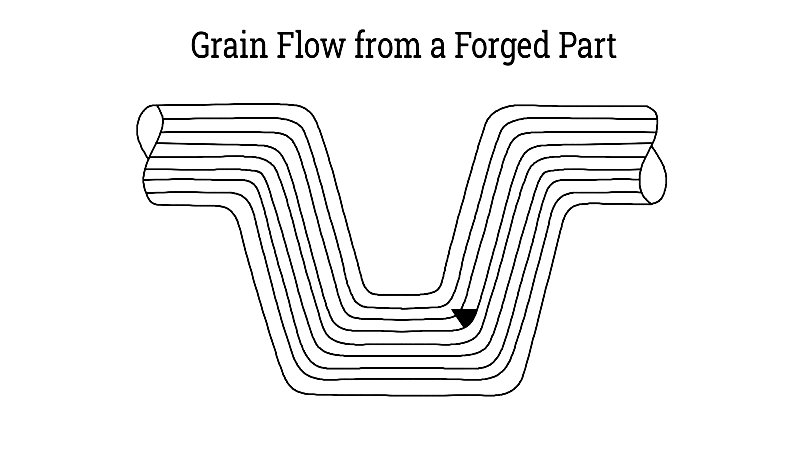

Optimizing Grain Structure

Forging enhances metal properties through grain alignment. Cold forging increases strength via work hardening, while hot forging improves impact resistance. Proper grain orientation significantly boosts component durability, making forged parts superior to cast alternatives.

Tempering Process

Tempering further refines forged metal properties by heating below critical temperature. This process balances strength and ductility while reducing brittleness. Adjustable parameters allow customization for specific applications, particularly for high-stress components.

Final Finishing and Inspection

Forging produces exceptionally strong components with superior internal structure. Post-forging processes like machining and testing ensure dimensional accuracy and quality. Rigorous inspections guarantee compliance with industry standards, ensuring reliability in demanding applications.