Introduction

- Principle of Silicone Tubing

- Types of Silicone Tubing

- Applications and Benefits of Silicone Tubing

- Cleaning, Sterilization, and Methods of Joining Silicone Tubing

- And much more…

Chapter 1: Understanding the Fundamentals of Silicone Tubing

This section explores the properties of silicone tubing and the manufacturing processes involved.

Defining Silicone Tubing

Silicone tubing is a durable elastomer known for its strength, flexibility, and resistance. It maintains flexibility even after repeated bending and twisting. Its non-toxic nature makes it ideal for medical applications, particularly in healthcare settings.

Capable of withstanding extreme temperatures and sudden changes, silicone tubing is widely used for liquid and gas transfer across industries. Its superior properties make it a preferred choice for various applications.

With excellent UV and heat resistance, silicone tubing suits electronics and aerospace industries. Easy to clean and sterilize, it's ideal for medical, pharmaceutical, and food production environments. Available in multiple sizes and grades, including high-temperature variants, it meets diverse industry needs.

High-temperature silicone tubing outperforms plastic or rubber in extreme conditions. FDA-approved food-grade tubing offers stability and heat resistance for food and beverage applications. Medical-grade tubing meets strict purity standards required in healthcare.

Production of Silicone Tubing

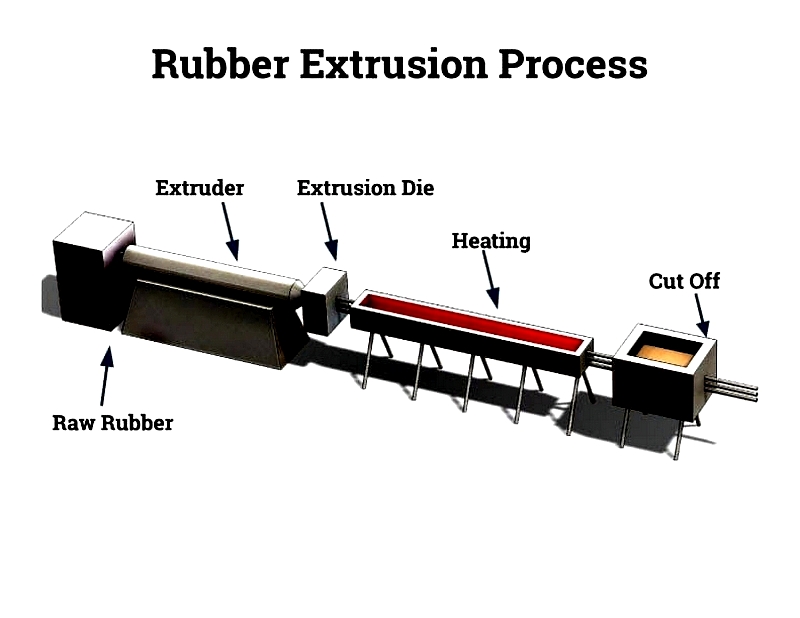

Silicone tubing is manufactured using rubber extrusion techniques.

The Extrusion Technique

Extrusion is efficient for large-scale production. The process begins with heating and curing silicone compound, then shaping it into slabs or strips.

The prepared silicone is fed into a screw extruder, which forces it through a steel die to form tubing. The tubing then cures continuously in a heated oven.

Curing methods include salt baths, steam vulcanization, and infrared processes. Material selection is crucial to ensure final product specifications are met.

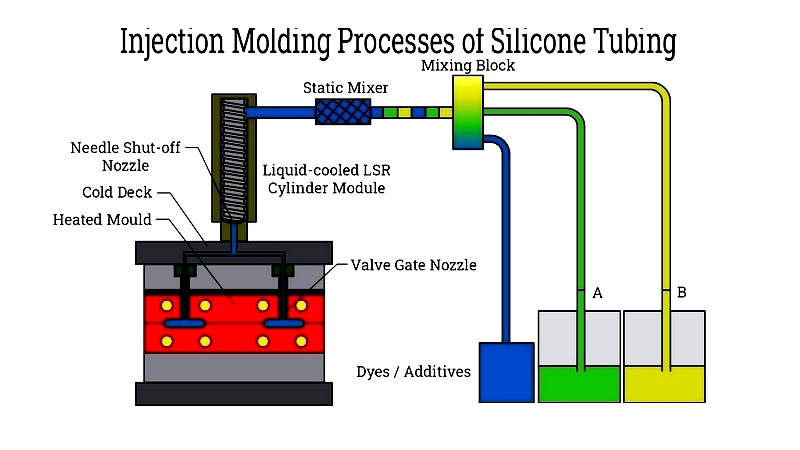

Comparing Extrusion and Injection Molding for Silicone Tubing

Extrusion produces long, circular shapes while molding handles irregular forms in limited lengths.

Extrusion creates continuous lengths, while injection molding produces complex structures with lower hardness. Injection-molded tubing is softer and suits power industry applications.

Silicone's insulating properties make it valuable in power systems. Both extrusion and injection methods can meet high-voltage requirements.

In healthcare, extrusion is used for standard piping while injection handles irregular shapes. Extrusion remains cost-effective for standard pipe production.

Dimensions of Silicone Tubing

Tubing dimensions determine its applications. Small tubing works for electrical sleeving, medium for precise fluid transfer, and large for durable applications like air ducts.

Medium tubing is preferred in pharmaceutical and food industries for hygiene. Platinum-cured tubing is widely used in medical and food sectors, ensuring product integrity.

Chapter 2: Types of Silicone Tubing

Different types include:

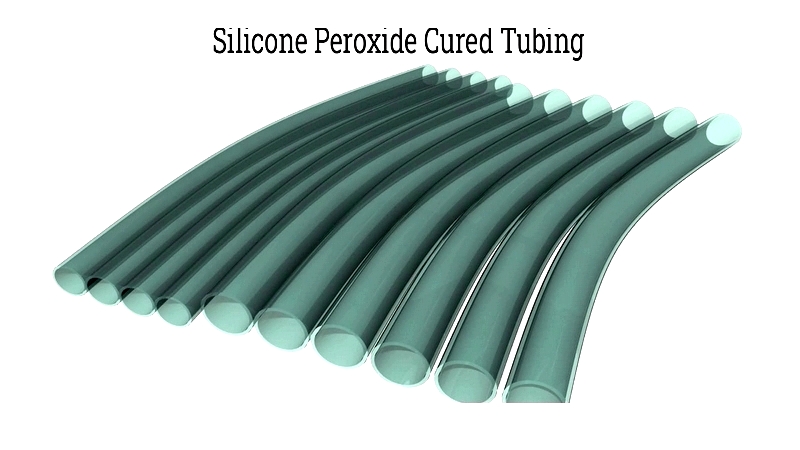

Silicone Peroxide Cured Tubing

This translucent tubing comes in various diameters for industrial use where ultra-high purity isn't critical. It's suitable for general transfer and insulation applications.

Used in automotive and appliance industries, it withstands temperatures up to 392°F (200°C). Cost-effective but may yellow over time in UV exposure.

Platinum-Cured Silicone Tubing

High-purity tubing for food, pharmaceutical, and biomedical uses. Offers superior flexibility and operates from -40°F to 392°F (-40°C to 200°C).

Available in translucent, black, or white. Complies with USP Class VI, FDA, and NSF-51 standards for regulated industries.

Silicone Dairy Tubing

Designed for dairy processing, it resists wear and repeated cleaning. Platinum-cured for purity and product integrity.

Smooth inner bore enhances flow and hygiene in milking systems and dairy processing equipment.

Silicone Fuel Tubing

Popular in RC hobbies for fuel resistance. Flexible for tight spaces and available in vibrant colors.

Not suitable for gasoline or diesel engines in full-scale vehicles.

High-Temperature Silicone Tubing

Withstands extreme temperatures for automotive, aerospace, and processing industries. Temperature ratings indicate maximum service limits.

Flexible but may fatigue with repeated bending. Verify chemical compatibility for critical applications.

Food-Grade Silicone Tubing

Ideal for food processing, free from BPA and phthalates. Maintains food integrity with no flavor transfer.

Advantages include temperature durability, NSF-51 certification, and environmental sustainability.

Medical-Grade Silicone Tubing

Meets strict standards for medical devices and pharmaceutical use. Biocompatible and sterilizable.

Key features include clarity for flow monitoring and temperature resistance for sterilization.

Overmolded Silicone Junctions

Reduces shear stress in bioprocessing applications. Provides smooth transitions for laminar flow.

Colored Silicone Tubing

Used for color coding and identification in labs and industry. Offers visual differentiation.