Introduction

This article provides comprehensive information about stainless steel 304 and 304L, including their applications.

You will learn about:

- The characteristics of Stainless Steel 304

- The manufacturing process of Stainless Steel 304

- Applications of Stainless Steel 304 and 304L

- Different grades of Stainless Steel 304

- And more...

Specifications for Stainless Steel 304 and 304L

ASTM A240 and ASTM A666

Stainless Steel 304 – 18/8

- AISI/SAE 304

- JIS SUS 304

- German Grade 1.4301

- ISO X5CrNi18.10

- UNI X5CrNi1810

- UNS S30400

- AFNOR Z6CN18.09

- BS 304S15

- UNE F.3551

- AMS 5513

Stainless Steel 304L - 18/9

- AISI/SAE – 304L

- German Grade 1.4307

- ISO X2CrNi18.9

- UNS S30403

- UNI X2CrNi189

- AMS 5511

- SUS 304L

Chapter One: What is Stainless Steel Grade 304?

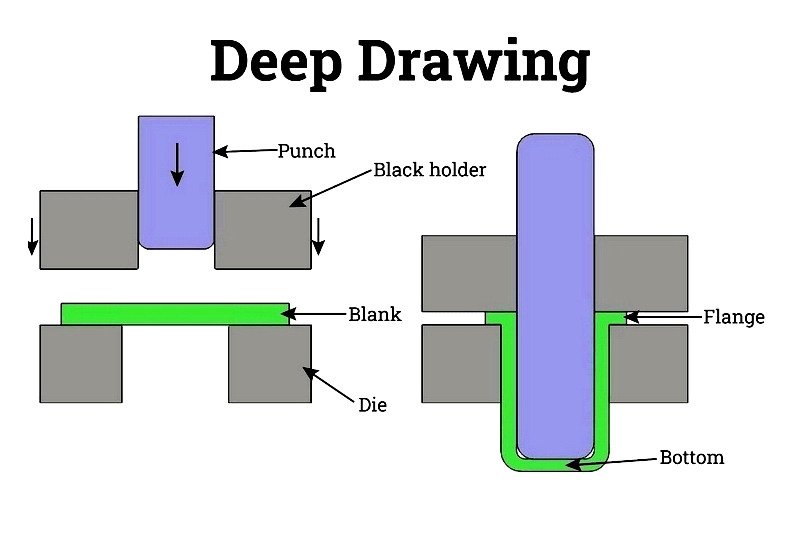

Stainless steel grade 304 is a versatile austenitic stainless steel widely used across industries. As part of the T300 series, it contains 18% chromium and 8% nickel (commonly called 18/8 stainless steel). Its excellent deep drawing capability allows it to withstand bending, cutting, and twisting forces during fabrication.

Available in various forms including plates, tubes, bars, and sheets, grade 304 offers exceptional heat and corrosion resistance along with high tensile strength and superior surface finish. These properties make it ideal for producing cutlery, tubing, fasteners, and electrical enclosures, while its adaptability supports both hot and cold forming processes.

Chapter Two: Comparing Stainless Steel Grades 304 and 304L with Other Grades

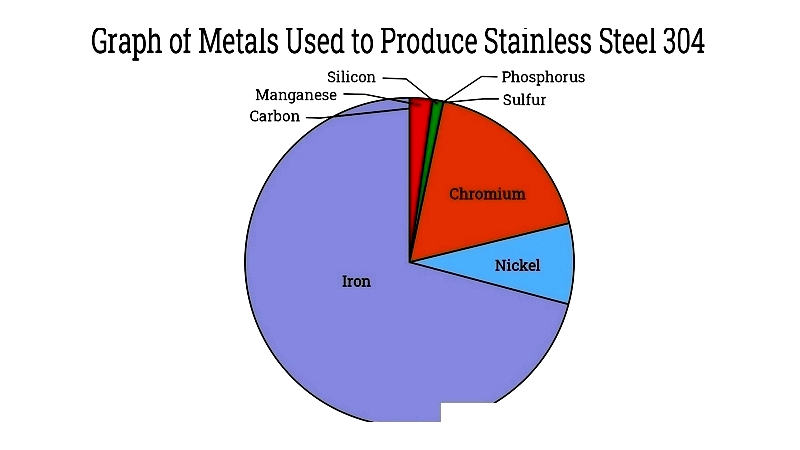

The primary differences between stainless steel grades lie in their chemical composition, microstructure, and alloy content. Grade 304 contains 18% chromium and 8% nickel, offering excellent corrosion resistance and weldability. In contrast, grade 316 provides superior chloride resistance due to its 2-3% molybdenum content. Both grades maintain structural integrity at high temperatures (1398.9°C to 1451.4°C).

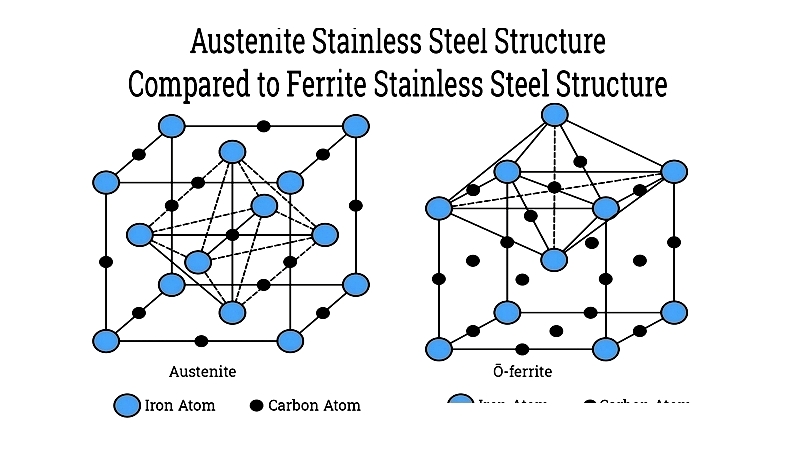

The passive chromium oxide layer that forms on stainless steel surfaces provides exceptional corrosion resistance and easy cleaning. This differs fundamentally from rust, as the protective layer remains chemically inert. Stainless steel's crystalline structure (austenitic, ferritic, martensitic, duplex, or precipitation-hardened) determines its mechanical properties and suitability for specific applications.

Chapter Three: Composition and Alloying Elements of Stainless Steel 304

Grade 304 stainless steel consists primarily of iron (67-71%), chromium (18-20%), and nickel (8-12%), with trace elements enhancing specific properties. The balanced composition ensures excellent corrosion resistance, formability, and strength for applications in construction, food processing, and medical industries.

Variants like 304L (low carbon) improve weldability, while 304H (high carbon) enhances high-temperature performance. Each alloying element contributes specific characteristics: chromium enables corrosion resistance, nickel stabilizes the austenitic structure, and manganese improves toughness.

Chapter Four: Different Grades of Stainless Steel 304

The 304 series includes standard 304, 304L (low carbon), and 304H (high carbon) variants. While sharing similar alloy compositions, their carbon content differences (0.08%, 0.03%, and 0.10% respectively) affect their mechanical properties and applications.

Properties of Stainless Steel 304 Grades

Grade 304 (UNS S30400)

With excellent formability and corrosion resistance, grade 304 features a tensile strength of 621 MPa and maintains oxidation resistance above 870°C. Its versatility makes it suitable for diverse industrial and commercial uses.

Grade 304L (UNS S30403)

The low carbon content (0.03%) minimizes carbide precipitation during welding, making 304L ideal for welded structures in corrosive environments without requiring post-weld annealing.

Grade 304H

With increased carbon content, 304H offers enhanced high-temperature strength while