Introduction

This article provides an in-depth exploration of dynamometers.

You'll discover information on various topics including:

- What is a Dynamometer?

- How Dynamometers Work

- Different Types of Dynamometers

- Dynamometer Testing Procedures

- And more...

Chapter One – What is a Dynamometer?

A dynamometer is a device that measures force, tension, weight, or pulling power. It calculates torque, force, velocity, and power by simultaneously assessing torque and rotational speed, which are crucial for motor operation.

Originally designed for measuring engine torque, dynamometers now also measure weight and tension. These instruments are essential for monitoring tension in telephone wires, suspension bridges, elevator cables, and ski lifts.

When used for tension measurement, dynamometers ensure safe operation of lifting equipment, cranes, and cables by precisely tracking loads and preventing overloading. Available in various designs for different applications, they're often chosen over crane scales due to their portability and easy setup.

Regular calibration is necessary to maintain a dynamometer's accuracy. Therefore, they incorporate multiple calibration methods and are built to endure various working conditions. This durability makes them vital for analyzing both pulling and pushing forces.

When force is applied to a dynamometer's flexible metal ring, the resulting deflection allows measurement of the force. This capability is particularly important in the automotive industry for determining horsepower, power absorption, and rotational speed. In construction, dynamometers help evaluate tension and pull forces on structural components to ensure strength and load capacity.

A key benefit of dynamometers is their versatility across numerous applications. Whether measuring torque or pull forces, they deliver exceptional accuracy and reliability.

Chapter Two – How a Dynamometer Works

To understand dynamometer operation, picture a spring with one end fixed to a base and the other attached to the measured force. As the force stretches the spring, a scale displays the measurement. This basic principle underlies mechanical dynamometers, similar to spring balances. Common measurement units include Newtons (N), pounds-force (lbf), and kilograms-force (kgf), making them suitable for diverse industrial and laboratory applications.

While this simple design works for basic force measurements, it lacks the capacity and precision needed for high-performance engines producing 250 hp or more. For such demanding applications, advanced engine or chassis dynamometers feature robust designs capable of handling greater power output, rotational speed, and dynamic load variations. These sophisticated devices ensure safety, durability, and accuracy in high-power testing environments.

Uses with Motors and Engines

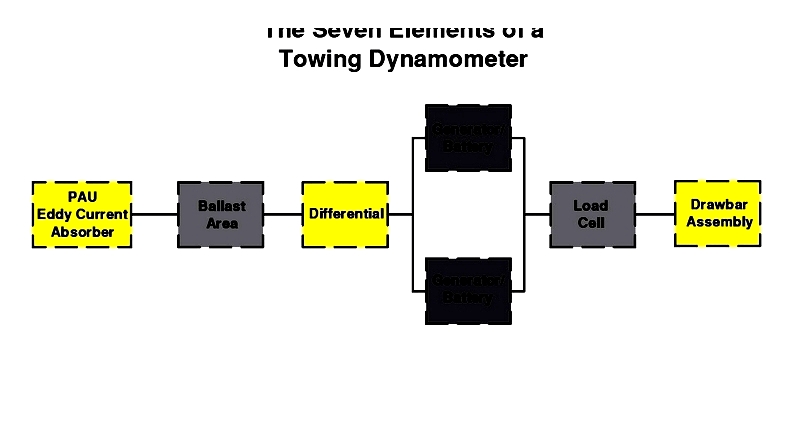

Large dynamometers act as variable loads (or load banks) connected to engine or motor output shafts. As the motor operates, the dynamometer absorbs and measures generated power, providing performance data like torque, brake horsepower (BHP), power curves, and RPM. The absorbed energy is typically dissipated through electromagnetic, hydraulic, or eddy current resistance to manage heat and kinetic energy during testing.

Modern dynamometer systems incorporate advanced data acquisition and analysis controlled by specialized software. These systems automate testing while providing real-time monitoring for engineers. Most industrial and automotive labs use Windows-based software for configurable data logging, visualization, and reporting, though some still employ DOS-based solutions for specific applications.

The software can display various readings and diagnostics including:

- Ambient temperature

- Barometric pressure

- Humidity

- Oil and coolant temperature

- Exhaust gas temperatures

- Airflow rate (CFM or L/s)

- Exhaust oxygen (O2) levels

- Throttle position sensor (TPS) angle

- Engine revolutions per minute (RPM)

- Intake manifold pressure (MAP)

- Crankcase blowby gas flow

- Fuel consumption rates

- Load cell force feedback

Dynamometer software enables comprehensive measurement and analysis of critical engine parameters. Manufacturers, OEMs, and testing facilities rely on this data for R&D, quality control, and emissions testing. Accurate measurements impact product reliability, efficiency, and compliance. Consistent testing is crucial, as even minor calibration errors can skew results. By analyzing multiple test runs, engineers can identify trends, correct performance issues, and optimize designs for maximum output and efficiency.

Engine and chassis dynamometers are indispensable for vehicle testing, racing, diagnostics, and quality assurance. They help evaluate modifications, conduct endurance tests, and validate warranty claims. High-precision dynamometer testing ensures accurate results, helping businesses meet industry standards and customer expectations.

Uses as a Force Gauge

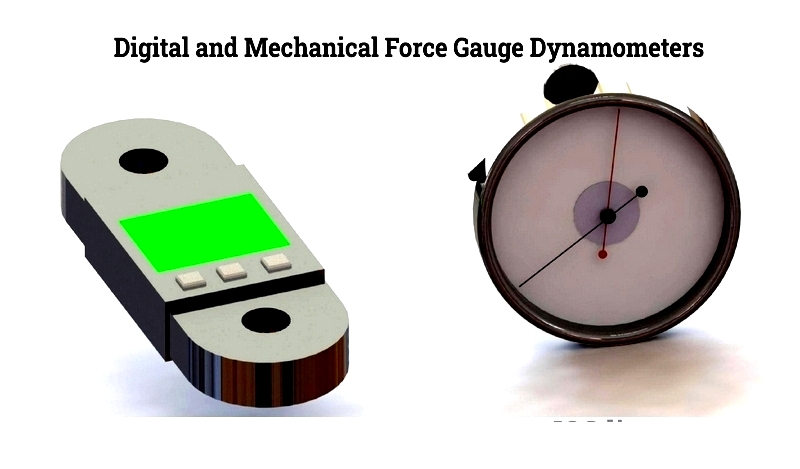

As force gauges, dynamometers measure both tensile (pull) and compressive (push) forces across various engineering fields. There are two primary types: digital and mechanical. Digital versions use load cell sensors to convert force into electrical signals displayed on LCD screens. Mechanical models typically employ strain gauges that deform under load, showing measurements through analog dials or electrical outputs.

Dynamometer force gauges provide measurements in standard units like Newtons (N), pounds-force (lbf), kilograms-force (kgf), and Pascals (Pa) for pressure. These highly accurate devices can measure forces ranging from delicate biomedical loads to massive industrial applications in construction and aerospace.

Beyond material testing, engineers use dynamometer force gauges for calibration, proof loading, overload detection, and equipment certification. Their durable construction, high-resolution sensors, and data logging capabilities ensure compliance with ISO, ASTM, and OSHA standards. Selecting the appropriate dynamometer—whether digital or mechanical, portable or bench-mounted—ensures superior accuracy and repeatability in force measurement.