Introduction

This article provides concise information about carrying cases and their uses.

You will learn about:

- What a Carrying Case is

- How Carrying Cases are Made

- How Carrying Cases are Used

- Different Types of Carrying Cases

- And much more...

Chapter One – Understanding Carrying Cases

Carrying cases provide a convenient way to organize and transport various items, regardless of their similarities or differences. They effectively protect and store everything from mobile phones to audio systems and technical gadgets, ensuring delicate materials remain safe during transport.

The design, configuration, and dimensions of carrying cases are specifically tailored to fit their intended contents. Depending on their purpose, carrying cases can be made from durable materials like reinforced fabric, plastic, aluminum, nylon, leather, wood, or combinations of these.

Some carrying cases are designed for specialized applications, as shown in the accompanying image, and are manufactured to meet precise specifications.

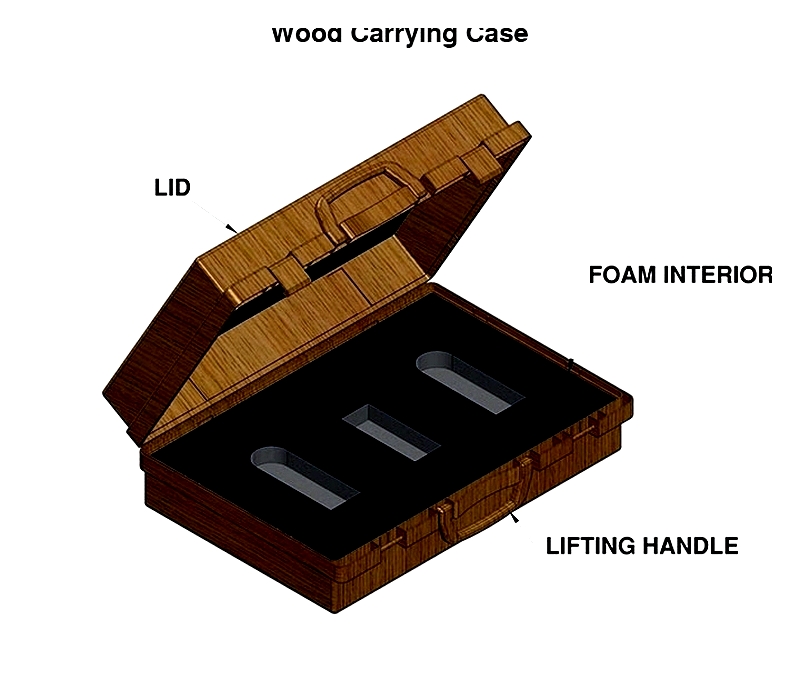

Many carrying cases feature foam inserts that are custom-molded to securely hold tools, devices, components, and delicate instruments in place.

Chapter Two – How Carrying Cases Are Made

The manufacturing process for carrying cases varies significantly based on their intended use and target industry. Standard off-the-shelf cases found in retail stores differ greatly from custom cases designed for specialized applications like transporting scientific instruments, medical devices, electronics, military equipment, and fragile items. Choosing the right design is crucial for users who need unique features, superior protection, or precise fits for sensitive equipment.

Carrying cases are made from various materials including aluminum, injection-molded plastic, engineered wood, heavy-duty fabrics (such as ballistic nylon), lightweight composite metals, and genuine or synthetic leather. High-performance cases must offer durability, flexibility, impact resistance, and portability. Some designs combine multiple materials to enhance structural integrity, water resistance, and longevity - essential for industries requiring rugged reliability.

Manufacturing Carrying Cases

The production process is customized to meet user requirements. Cases designed for air travel, industrial shipping, or secure transport must comply with strict guidelines regarding weight, materials, closure mechanisms, and locking capabilities. Premium manufacturers often exceed basic standards by offering reinforced corners, pressure-release valves, tamper-resistant latches, and custom foam inserts for shock absorption.

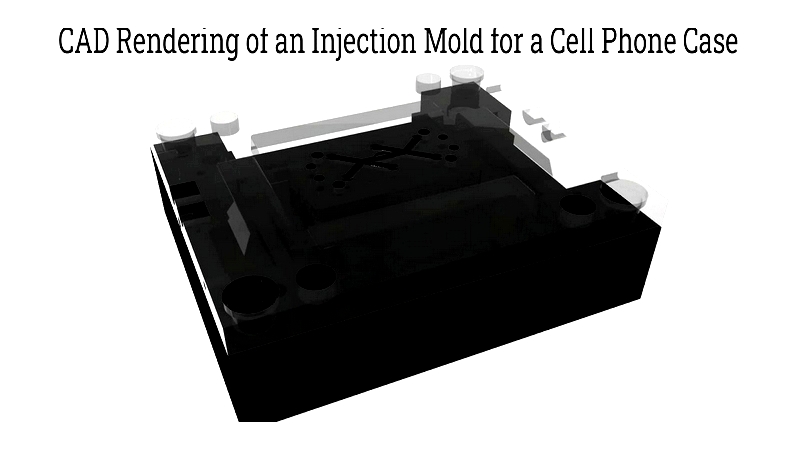

Choosing between stock and custom cases is critical for protecting valuable equipment. Custom manufacturers offer services like CAD prototyping, 3D printing, and CNC machining to create optimal solutions for specific applications.

Materials for Carrying Cases

Manufacturers select materials based on cost, weight, and performance. Lightweight metals, industrial-grade polymers, and durable textiles like ballistic nylon and neoprene are commonly used. Plastic cases may feature abrasion-resistant coatings, custom foam liners, or anti-static finishes for electronics.

Plastic Cases

Plastic is the most popular material for modern carrying cases due to its versatility, UV-resistance, and cost-effectiveness. Molded plastic cases range from small tool cases to large wheeled containers for industrial equipment.

Engineered plastics allow for customized shapes, compartments, and aesthetics, making them ideal for aerospace, electronics, photography, and laboratory applications. Rugged outdoor cases often feature enhanced sealing for dust and waterproof protection.

The strength and lifespan of plastic cases depend on the resin type. Common plastics include HDPE, FRP, carbon fiber composites, ABS, polycarbonate, and LLDPE, each offering specific benefits for different applications.

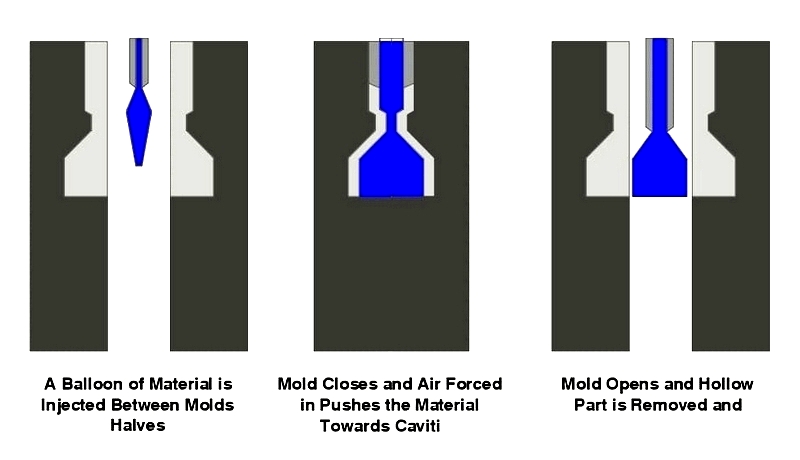

Blow Molded Plastic Cases

Blow molding creates durable cases with even wall thickness for tools, instruments, and retail displays. This process is valued for its shock-absorbing properties and cost-effectiveness.

Thermoforming Process

Thermoforming uses heat to shape plastic sheets into 3D products. Advanced techniques include vacuum, pressure, and mechanical forming for precise case production.

These methods enable rapid manufacturing of protective packaging and custom cases for medical devices and other specialized applications.

Injection Molding

Injection molding produces detailed cases with precision. This method is ideal for phone cases, electronics enclosures, and instrument cases, offering consistency in high-volume production.

Rotational Molding

Rotomolding creates large, rugged cases for industrial, defense, and film production. This process forms seamless products with heavy-duty features for demanding applications.

Rotomolded cases can include double walls, gasketed lids, and recessed hardware to meet military standards. The method allows for custom sizes and features.

Aluminum Cases

Aluminum cases offer strength, corrosion resistance, and professional appearance. They're popular in aerospace, military, and broadcasting for their durability and modularity.

Larger cases may include telescoping handles, reinforced wheels, and stackable designs for optimal portability.

Neoprene Cases

Neoprene provides flexibility and weatherproofing for electronics sleeves and camera bags. Its shock absorption makes it ideal for mobile professionals.

Nylon Cases

Nylon cases are durable options for audio, video, and IT equipment. Advanced nylon blends enhance abrasion resistance for heavy-duty use.

Leather Cases

Leather cases range from rugged full-grain to stylish top-grain options. Premium cases feature reinforced stitching and custom linings for protection and appeal.

Wood Cases

Wooden cases combine elegance with durability. Hardwood cases with custom linings are popular for scientific, presentation, and collectible applications.

Carrying Case Design

Case design involves needs assessment, prototyping, and evaluation. Advanced software ensures cases meet specifications for protection and usability.

ATA-certified cases undergo rigorous testing to ensure they meet commercial transit standards. These cases often feature composite construction and reinforced hardware.