Introduction

This comprehensive guide covers everything about rubber latches and their applications.

You'll discover:

- The fundamentals of rubber latches

- Various types available

- Manufacturing processes

- Materials used in production

- Design considerations

- Practical applications

Chapter One: Understanding Rubber Latches

Rubber latches serve numerous industries by securely fastening items, surfaces, and openings. Their unique blend of flexibility and strength, combined with reliable gripping power, makes them essential across various sectors. Typically made from rubber or containing rubber components, these fasteners are widely used in automotive, aerospace, and medical equipment due to their durability. They provide tight closures for doors and lids while effectively sealing surface interfaces.

A typical rubber latch features an elastic strap connected to a frame, designed to stretch and secure openings. The key characteristic is its elasticity, allowing it to hook over anchors or knobs. The resulting tension ensures the latch remains firmly closed.

These fasteners stand out for their adaptability, longevity, and ease of use. Their flexible nature and secure grip make them ideal for stabilizing equipment, even in challenging conditions. As technology advances and new materials emerge, rubber latches continue evolving while maintaining their relevance in modern fastening systems.

Chapter Two: Varieties of Rubber Latches

The market offers diverse rubber latch types to meet various industrial and consumer needs. They range from all-rubber designs to hybrid models combining rubber with metals like stainless steel. These variations address specific operational, environmental, and sealing requirements across multiple industries including automotive, marine, industrial, and medical sectors.

Hybrid Rubber-metal Latches

Toggle Latches

These combine metal toggles with rubber catches for vibration-resistant closures, particularly valuable in marine applications where corrosion resistance is crucial. Features often include stainless steel components and adjustable tension mechanisms.

Magnetic Latches

Incorporating magnets with rubber catches, these provide quiet, scratch-free closures ideal for cabinets and electronic enclosures. Their simplicity makes them popular for consumer electronics and laboratory equipment.

Pull Latches

Featuring ergonomic rubber handles with metal bases, these offer easy operation and vibration dampening, making them automotive industry favorites for vehicle compartments and machinery panels.

Snap Latches

Using rubber elasticity and metal springs, these provide audible closure /confirm/iation, commonly found in medical equipment and laboratory settings where frequent access is required.

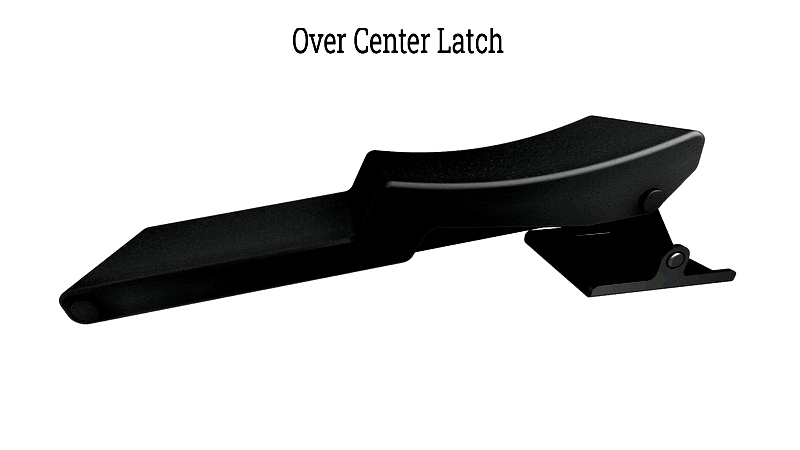

Over-Center Latches

These heavy-duty latches combine rubber with preloaded springs for industrial and transportation applications, maintaining secure closures under vibration or impact.

All-Rubber Latches

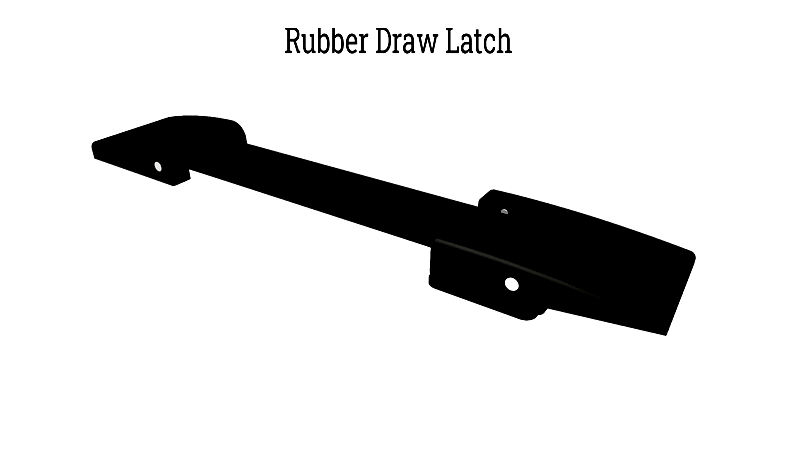

Rubber Draw Latches

Constructed entirely from weather-resistant rubber, these excel in marine and automotive applications requiring watertight seals.

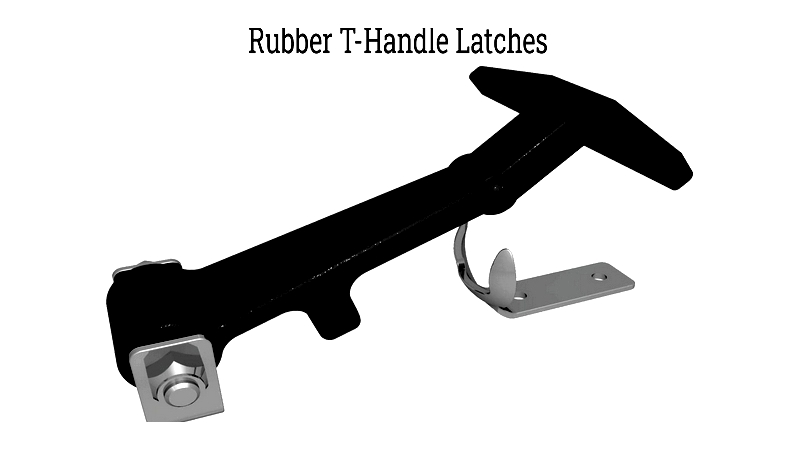

T-Handle Latches

With molded rubber handles, these allow easy operation even with gloves, ideal for outdoor equipment and agricultural machinery.

Rubber Pull Latches

These flexible designs create weatherproof seals for various applications, offering UV and temperature resistance for automotive and marine use.

Selection Considerations

Key advantages include:

- Weather Resistance: Excellent sealing against moisture and dust

- Durability: High tensile strength and chemical resistance

- Noise Reduction: Vibration absorption properties

- User Safety: Ergonomic designs prevent pinching

- Corrosion Resistance: Ideal for harsh environments

Selection should consider industry standards, load requirements, environmental conditions, and frequency of use. For specialized solutions, consult manufacturers or visit resource pages.

Chapter Three: Manufacturing Processes

Rubber latch production employs advanced techniques tailored to performance requirements and material properties. The chosen method depends on design complexity, production volume, and intended application.

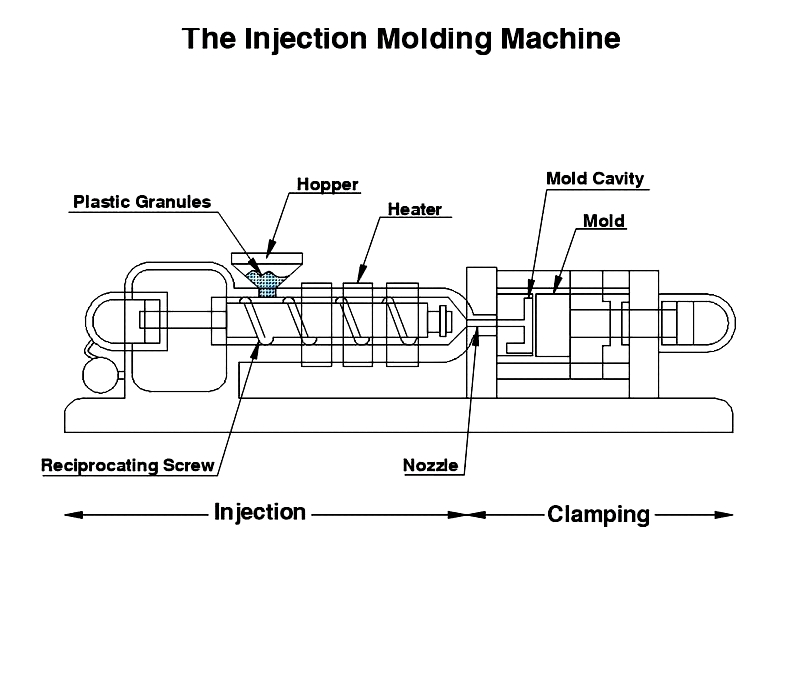

Injection Molding

Ideal for complex shapes and mass production, this method offers tight tolerances and material versatility, commonly using silicone or nitrile rubber.

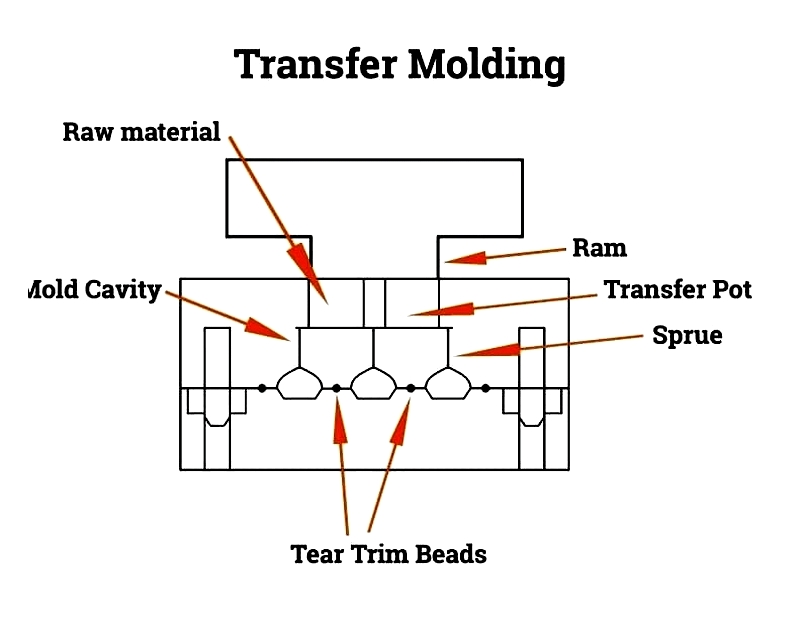

Transfer Molding

This process provides precise material control for medium-volume production, particularly for parts requiring metal insert encapsulation.

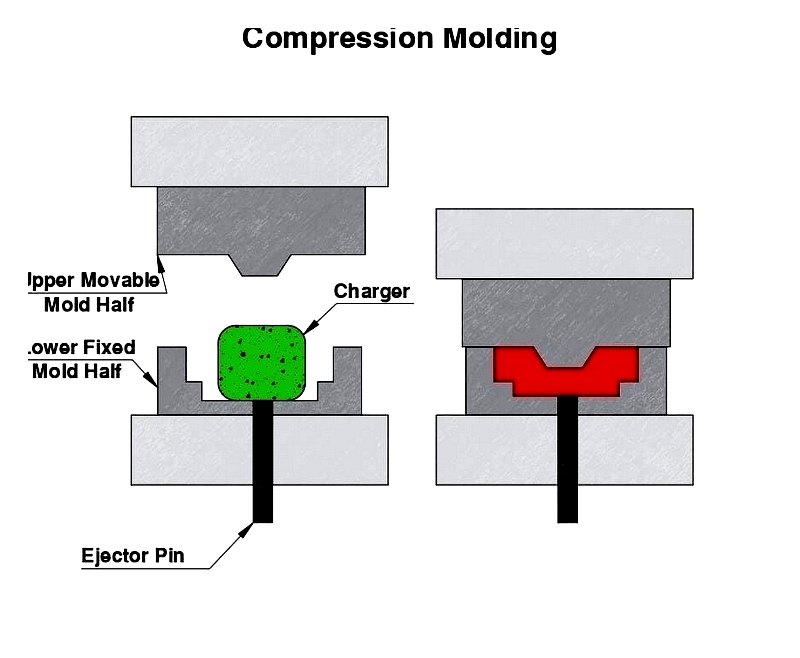

Compression Molding

Cost-effective for simpler designs and lower volumes, this method accommodates various elastomers for custom or replacement parts.

Liquid Injection Molding

Perfect for high-precision components, this technique produces parts with excellent dimensional stability, often using liquid silicone rubber.

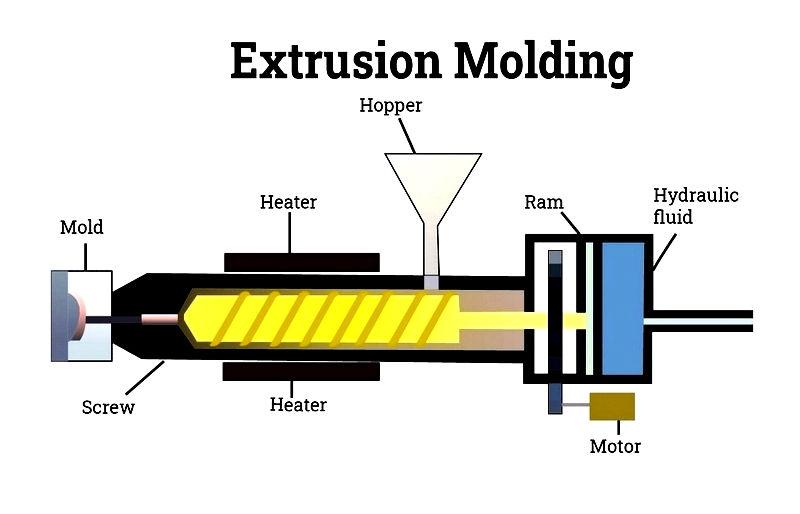

Extrusion

Primarily for creating continuous rubber profiles used in latch assemblies, offering uniform cross-sections for sealing applications.

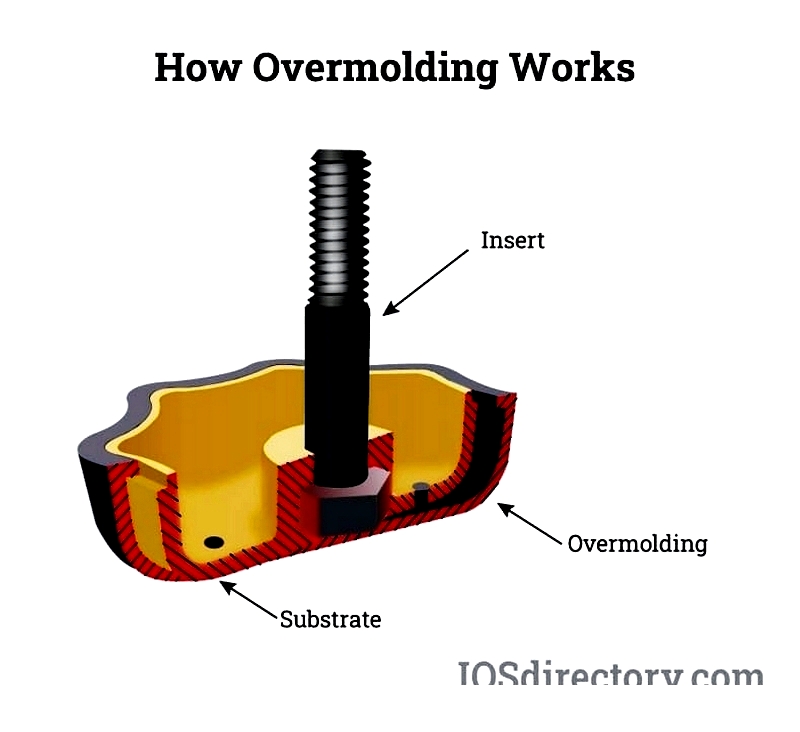

Overmolding

This process bonds rubber to substrates, enhancing grip and protection in demanding industries like automotive and aerospace.

Each manufacturing method enables production of latches optimized for specific performance criteria, ensuring reliability in various environments.

Chapter Four: Rubber Materials

The choice of rubber significantly impacts latch performance, with different types offering varying strength and environmental resistance.

Natural Rubber

Known for tear resistance and durability, though susceptible to heat and ozone. Commonly molded via injection or compression processes.

Neoprene

Excellent weather resistance makes it ideal for outdoor and marine applications, typically molded using standard techniques.