Introduction

This guide covers everything you need to know about neodymium magnets and their applications.

You will learn about:

- What Neodymium Magnets Are

- Key Properties of Neodymium Magnets

- How Neodymium Magnets Are Manufactured

- Common Applications of Neodymium Magnets

- And much more...

Chapter One – Understanding Neodymium Magnets

Neodymium magnets, commonly called Nd-Fe-B magnets, are powerful rare earth magnets made from an alloy of neodymium (Nd), iron (Fe), boron (B), and other transition metals. Known for their exceptional magnetic field strength—reaching up to 1.4 teslas (T)—they deliver outstanding performance in various applications due to their high magnetic flux density.

These magnets are produced through two main methods: sintering and bonding. Since their introduction in 1984, they have become the most widely used magnets thanks to their superior strength and efficiency.

While pure neodymium is ferromagnetic, it only becomes magnetized at extremely low temperatures. When alloyed with iron, however, it achieves magnetization at room temperature.

Rare earth magnets include both neodymium and samarium cobalt types. Before neodymium magnets became dominant, samarium cobalt magnets (SmCo) were the standard. However, neodymium magnets have largely replaced them due to the high production costs of samarium cobalt.

Although less powerful than neodymium magnets, samarium cobalt magnets offer better high-temperature tolerance and corrosion resistance, making them suitable for demanding environments where durability is essential.

Chapter Two - Properties of Neodymium Magnets

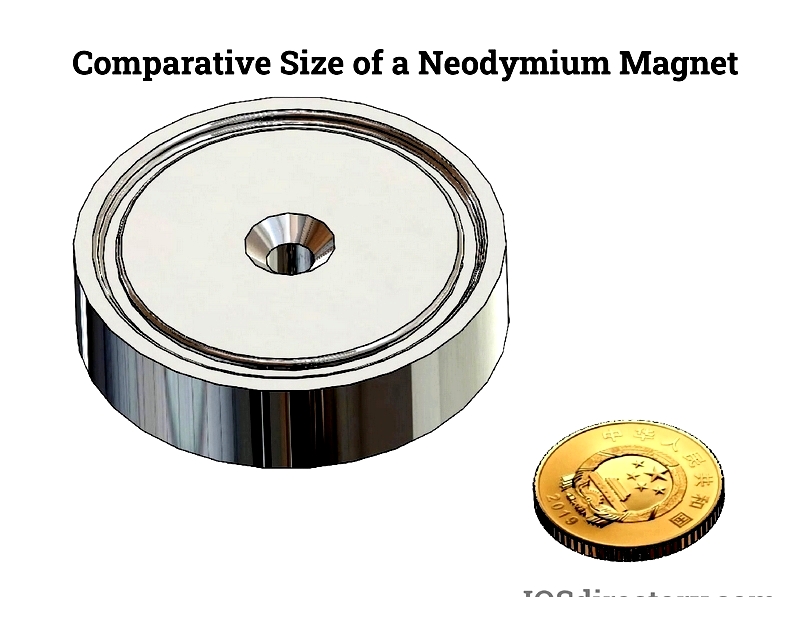

Neodymium magnets, also known as NdFeB or rare earth magnets, are celebrated in the magnet industry for their remarkable strength and compact size. As the strongest commercially available permanent magnets, they have transformed modern technology, powering devices from electric motors and wind turbines to headphones and medical equipment. Their exceptional strength comes from the alignment of atomic dipoles under a magnetic field, a phenomenon captured in their magnetic hysteresis loop. Even after the external field is removed, neodymium magnets retain much of this alignment, making them highly efficient for diverse applications.

Understanding neodymium magnet grades is crucial for selecting the right magnet for specific industrial or consumer uses. Grades indicate the maximum energy product, measured in mega gauss oersteds (MGOe), which reflects peak values in the BH Curve—a key determinant of magnet strength and efficiency. Higher grades signify stronger magnets with greater magnetic field intensity and better resistance to demagnetization.

The "N" grading scale ranges from N30 to N52, with advanced applications like aerospace and electronics now utilizing N55 magnets, which offer 6% greater strength than N52. Suffixes such as SH (Super High), UH (Ultra High), and EH (Extra High) denote enhanced coercivity (Hc), measuring a magnet's ability to maintain magnetization at high temperatures. Choosing the right grade and temperature rating is vital—higher coercivity ensures neodymium magnets perform reliably in high-heat environments.

While N52 was once the strongest neodymium magnet available, the development of N55 magnets has expanded possibilities for compact yet powerful designs. Industries such as renewable energy, electronics, and automotive manufacturing increasingly rely on premium grades like N52 and N55 where maximum magnetic flux and space efficiency are critical.

The table below compares the most common neodymium magnet grades to help users select the best option for their needs.

The table below shows the maximum working temperatures for each neodymium magnet grade. Selecting the appropriate grade is essential, as exceeding recommended temperatures can reduce magnetic strength or cause permanent demagnetization. The "XX" represents the maximum energy product in MGOe, a critical factor when evaluating magnets for motors, sensors, medical devices, and other advanced applications.