Introduction

This article provides a comprehensive overview of plastic corrugated boxes.

By the end of this reading, you will understand:

- The fundamentals of plastic corrugated boxes: their composition, functionality, and selection criteria

- The manufacturing process of plastic corrugated boxes

- Various types of plastic corrugated boxes available

- Applications, benefits, and limitations of plastic corrugated boxes

- And more...

Chapter One: Understanding Plastic Corrugated Boxes

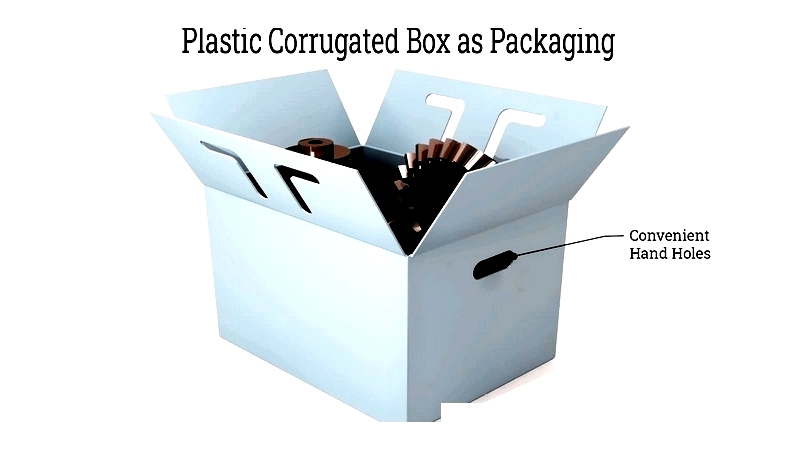

Transporting goods frequently damages cardboard boxes due to tearing, leaks, and exposure to moisture, chemicals, and dust. Plastic corrugated boxes provide a durable, reusable alternative that saves time, money, and resources.

Composition

Plastic corrugated boxes consist of three layers: inner, outer, and middle. Made primarily from polypropylene (also called polyflute or corflute), these containers offer excellent protection during storage and transportation. Available in thicknesses from 2mm to 25mm, they're lightweight, recyclable, and resistant to chemicals, dust, and water.

Functionality

The durable polypropylene construction makes these boxes shock-resistant and portable. Their neutral pH and temperature resistance ensure product protection in various environments. The design effectively minimizes damage from impacts while preventing moisture penetration and maintaining structural integrity.

Selection Criteria

Choosing appropriate packaging requires balancing weight, aesthetics, security, and cost. Plastic corrugated boxes come in numerous configurations to meet specific needs.

Transportation Method

Consider the shipping method when selecting boxes. Land transport requires durability for rough roads, while air transport needs pressure and temperature adaptability.

Moisture Resistance

Unlike cardboard, plastic corrugated boxes resist water damage. Ensure the assembly adhesive is also moisture-resistant for complete protection.

Product Dimensions

Match box size and thickness to the product's weight and dimensions. The wide range of available sizes accommodates various requirements.

Temperature Variations

Plastic corrugated boxes withstand extreme temperature fluctuations, making them suitable for global shipping.

Product Value

The three-layer construction (inner liner, fluted middle, outer liner) provides dimensional stability and weight support. Higher-value items may require thicker plastic for added protection.

Fragile Items

Delicate products benefit from double-walled boxes with partition inserts. Custom configurations are available for specific protection needs.

Product Characteristics

Internal cushioning materials (air pads, foam, etc.) prevent damage. For electronics, consider ESD protection and corrosion resistance features.

Chapter Two: Manufacturing Process

Plastic corrugated boxes follow a standardized production process using three polypropylene layers (plastic cardboard). Specialized machines create both the boards and final boxes.

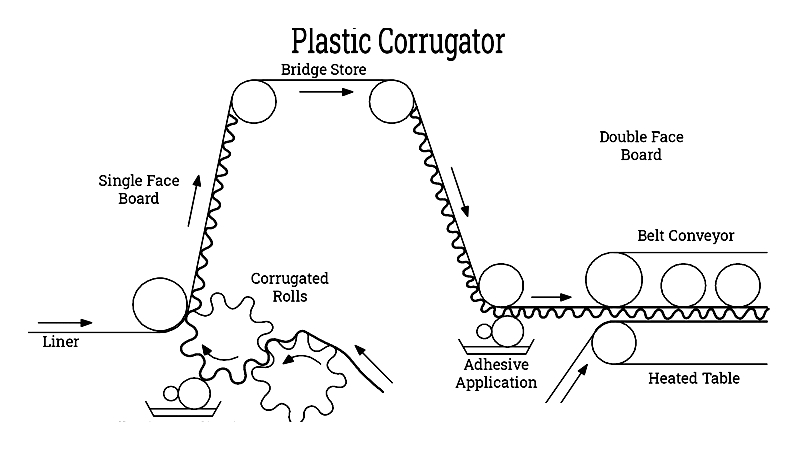

Corrugator Machine

This equipment produces single, double, or triple-wall boards through two stages: containerboard combining and box formation. Interchangeable rolls adjust flute sizes during production.

The process begins with plastic material feeding through preheating and corrugating rollers. A second liner aligns with the fluted material at the bridge section, where bonding creates durable corrugated boards.

Box Formation

A slitter-scorer cuts the boards into box blanks, which are then stacked and folded along pre-scored lines. Adhesive application completes the box assembly.