Introduction

This article provides an in-depth exploration of Automated Guided Vehicles.

You will learn about various topics including:

- The history of "driverless" vehicles

- Different types of AGVs

- Advantages of automation

- Common AGV components

- AGV guidance and navigation systems

- AGV safety and compliance standards

How did "driverless" vehicles evolve?

In 1954, Arthur "Mac" Barrett of Barrett Electronics Corporation developed the first AGV called Guide-o-Matic, which he described as a driverless vehicle due to its autonomous operation. Originally designed as a towing machine, Guide-o-Matic navigated by following signals from ceiling wires, later replaced with floor-embedded wires. Its main function was transporting trailers within warehouse environments.

Barrett focused on researching various automation techniques for tasks including door operation, material handling, and labor-saving devices. His radio-controlled industrial vehicles, named Radox, allowed operators to program them for pallet handling, vehicle towing, or pallet truck alignment.

Barrett's pioneering work inspired engineers to develop modern AGV systems using cameras, lasers, electrically conductive tape, and other technologies for vehicle navigation across different settings. The creation of automatic guided vehicles revolutionized the transportation of both raw materials and finished products.

What are AGVs?

Automated Guided Vehicles (AGVs) are sophisticated computerized vehicles designed for automated material handling in industrial environments. Equipped with advanced software, sensors, and navigation controls, AGVs autonomously determine their position, route, and movement throughout facilities. These self-driving mobile robots typically operate on battery or electric power, efficiently performing logistics functions like manufacturing, warehousing, loading, unloading, and inventory management—significantly reducing human involvement in repetitive or dangerous tasks.

Self-powered AGVs specialize in load transfers, pallet handling and stacking, automated material transportation, assembly line operations, and heavy load towing. These functions—previously performed by human workers or traditional forklifts—are now optimized for safety, productivity, and precision with AGVs, leading to measurable improvements in production efficiency and workplace safety. AGVs effectively reduce human exposure to hazardous conditions, lower labor costs, and minimize errors common in manual material handling.

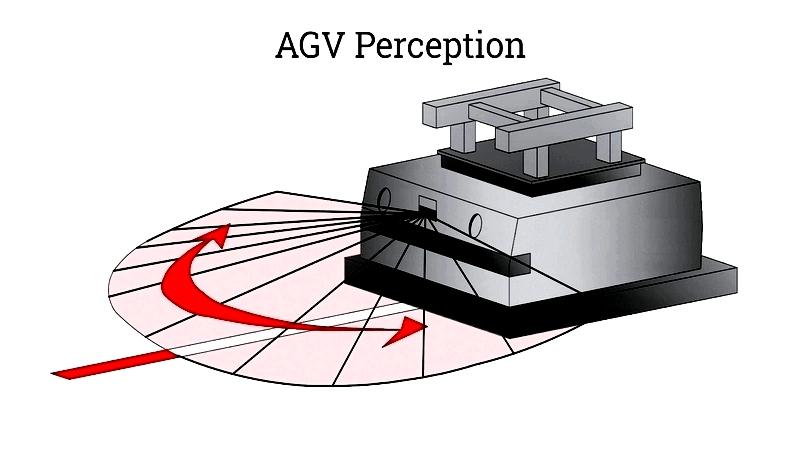

While the term AGV seems straightforward, these vehicles employ various navigation technologies including magnetic floor wires, optical cameras, RFID, radio waves, LiDAR, GPS, lasers, and other sensor-based systems. This enables AGV integration with smart automation systems and Industry 4.0 initiatives, supporting flexible material movement in factories, warehouses, and distribution centers. Modern AGV fleets often include management software and compatibility with warehouse systems, enabling real-time route optimization and coordination with other automated equipment.

The development of AGVs began with automated towing vehicles designed to enhance material flow in industrial plants. Initially seen as time-saving tools, AGVs have evolved significantly. By the late 20th century, engineers expanded AGV capabilities, improving factory automation, worker safety, and just-in-time delivery. Today, AGVs serve essential roles across industries—from automotive to pharmaceuticals—handling tasks ranging from heavy transport to precise assembly. ongoing technological advancements have produced diverse AGV types including tow tractors, unit load carriers, forklift AGVs, and custom mobile robots, each addressing specific material handling needs.