Introduction

This is the most comprehensive online guide available about rubber sheets.

You'll discover:

- Principles of Rubber Sheets

- Various Types of Rubber Sheets

- Applications and Advantages of Rubber Sheets

- And much more...

Chapter 1: Core Principles of Rubber Sheets

This chapter explains what rubber sheets are, how they're made, and their wide range of uses.

What Are Rubber Sheets?

Rubber sheets are flat materials made from rubber or rubber-coated fabric, designed to improve properties like tensile strength and reduce stretching.

This versatile material is used in oil and petroleum applications like fuel pumps and control valves, as well as across various industries.

How Rubber Sheets Are Made

Production depends on factors like dimensions, thickness, color, and intended use.

Rubber Sheet Materials

Common types include recycled, reclaimed, synthetic, and natural rubber. Recycled rubber comes from old tires, while reclaimed rubber undergoes de-vulcanization. Synthetic rubber is petroleum-based, and natural rubber comes from rubber trees mainly grown in South America, Africa, and Asia.

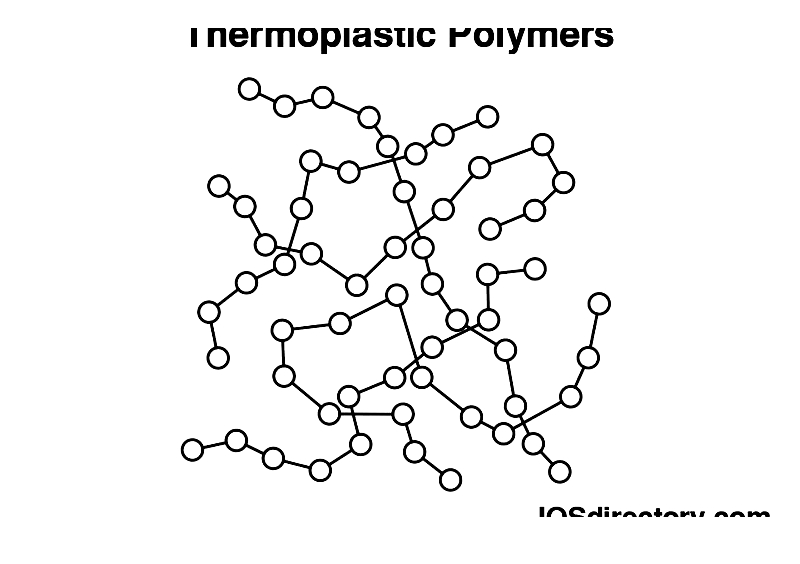

Thermoplastic Polymers

Materials like Polystyrene and Polypropylene can be remolded multiple times. Blended polymers may degrade during recycling but can be stabilized with additives.

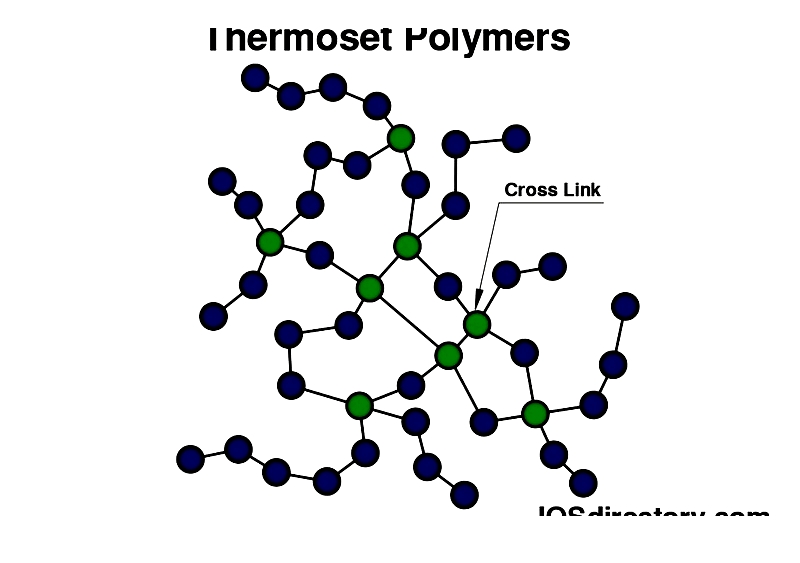

Thermoset Polymers

These form permanent molecular bonds during curing, differing significantly from thermoplastics.

Rubbers in Rubber Sheets

Rubbers are thermoplastic before vulcanization, allowing reshaping. Vulcanization creates cross-links, though de-vulcanization remains challenging.

Compounding Ingredients

Polymers are enhanced with mineral fillers to achieve specific properties, especially in rubbers and thermosets.

Choosing Rubber Sheet Materials

Key selection factors include:

- Thickness: important for gaskets and seals

- Temperature Resistance: Must withstand operating temperatures

- Abrasion Resistance: Critical for wear-prone applications

- Environmental Resistance: To ozone and UV exposure

- Oil Resistance: For petroleum applications

- Acid Resistance: Essential in chemical environments

- Hardness: Measured on the Shore scale

- Tensile Strength: Breaking force measurement

- Elongation: Stretch capacity before breaking

- Compression Set: Recovery after compression

- Specific Gravity: Density comparison to water

Manufacturing Processes

Four main techniques: molding, extrusion, latex dipping, and calendaring.

Molding

Uses molds for complex shapes in small quantities, including compression and injection molding.

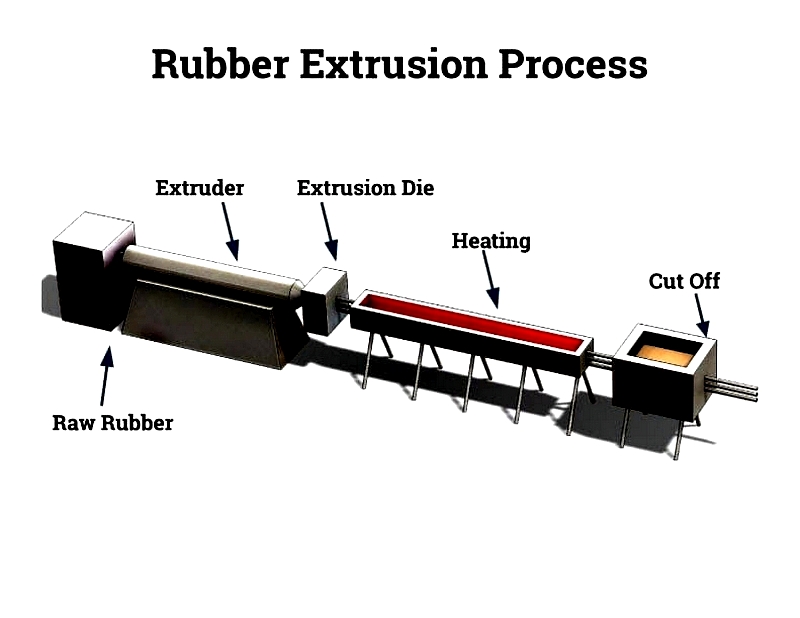

Extrusion

Forms unvulcanized compound through dyes for high-volume production.

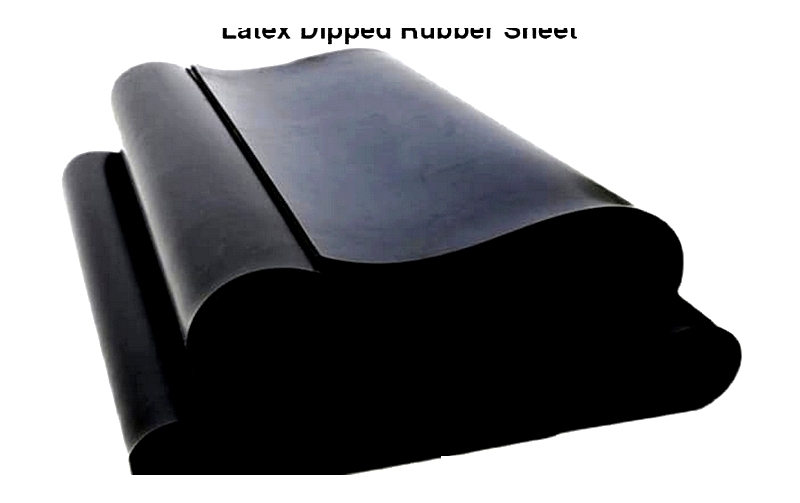

Latex Dipping

Dips molds in latex for thin products like gloves.

Calendering

Uses rollers for precise thickness in wide sheets.

Joining Methods

Bonding through adhesives or vulcanization, with vulcanized joints being more durable.

Rubber Sheet Specifications

Key standards include:

ASTM D1056

Covers flexible cellular rubber products like sponge rubber.

MIL-R-3065

Specifies requirements for synthetic rubber in fabricated products.

Chapter 2: Types of Rubber Sheets

Rubber sheets serve diverse industrial needs with their insulating, sealing, and protective properties. Here are the main types:

Natural Rubber Sheets

Made from rubber tree latex, offering excellent flexibility and tear resistance for anti-vibration applications.

Neoprene Rubber Sheets

Resistant to weather, flames, and chemicals, ideal for electrical insulation and marine uses.

Soft Neoprene

40A durometer for maximum conformity in seals and dampers.

Medium Neoprene

60A durometer for versatile gasket applications.

Nitrile Rubber Sheets

Excellent oil and fuel resistance for automotive and food processing industries.

EPDM Rubber Sheets

Weather-resistant material for roofing and outdoor applications.

Silicone Rubber Sheets

Heat-resistant and non-toxic for medical and food industries.

Fabric Reinforced Rubber

Added strength for high-stress applications like conveyor belts.