Introduction

This article provides an in-depth look at industrial furnaces.

You will learn about topics such as:

- What is an industrial furnace?

- What are the uses of an industrial furnace?

- Types of industrial furnaces

- The components of an industrial furnace

What Defines an Industrial Furnace?

An industrial furnace is designed to heat treat metals through processes like annealing, tempering, carburizing, or pre-treating before forging. While metals are the most common materials processed in industrial furnaces, these machines can also heat materials such as glass and certain ceramics for shaping. The primary function of an industrial furnace is to raise material temperatures to extremely high levels using various fuels and structural designs.

Although both industrial ovens and furnaces heat materials during processing, they differ in temperature capabilities and applications. Industrial ovens typically operate between 250°F and 900°F, while industrial furnaces can reach much higher temperatures, often exceeding 2000°F.

Industrial furnaces come in various designs and configurations. Some are compact, portable units with shelving and swing-open doors, commonly used in laboratories for material testing. Research labs use muffle furnaces for product testing, while dental labs employ them for zirconia binder burnout.

In large metallurgical facilities, furnaces often feature conveyor systems to handle high volumes of material. These automated systems use direct-fired or induction heating methods and play a crucial role in metallurgical extraction and smelting operations.

Industrial furnaces operate at different temperatures depending on the material's melting point and processing requirements. They consist of multiple chambers for loading, heating, and cooling. The heating zone can reach temperatures above 3000°F for demanding applications, constructed from durable materials like silicon carbide or nickel chromium alloys. Cooling chambers may use cold air or water baths to lower material temperatures after processing.

What Are the Uses of an Industrial Furnace?

While industrial furnaces are essential for metallurgical operations involving metal molding and shaping, they are also vital across many industries requiring controlled high-temperature processing. Industrial furnaces are used wherever materials need heating for manufacturing, treatment, or transformation. Modern technology relies on products that must be plasticized, sintered, or deformed to achieve precise shapes, making industrial furnaces crucial for uniform, reliable heating.

For centuries, metallurgical companies have used industrial furnaces for smelting and heat treating metals like steel, aluminum, and copper at high temperatures. These furnaces handle melting operations ranging from 550 lb. (250kg) to as little as 2 lb. (1kg), supporting foundry operations and precision heat treatment in automotive and aerospace manufacturing.

Chemical processors use industrial furnaces to synthesize specialty chemicals and catalyze reactions for manufacturing polymers and ceramics. Power generation companies use them to produce steam for turbines, while waste management facilities employ incineration furnaces for landfill waste. Mining operations use furnaces to extract metals from ores through pyrometallurgical processes.

Different industries require specialized furnaces. The fuel oil industry uses ashing furnaces to analyze ash content, while annealing furnaces soften metals before mechanical processing. Other types include muffle, blast, rotary kiln, electric arc, and vacuum furnaces, serving industries from metalworking to electronics.

As technology advances, industrial furnace applications continue to evolve. Industry 4.0 enables smarter process control and real-time monitoring. Modern furnaces feature emission control systems and waste heat recovery to minimize environmental impact and improve efficiency.

When selecting an industrial furnace, organizations must consider factors like furnace type, maximum temperature, heating uniformity, and energy efficiency. Partnering with reputable manufacturers ensures compliance with industry standards and long-term profitability.

What Are the Different Types of Industrial Furnaces?

Industrial furnaces have been essential to manufacturing for thousands of years, originally used to heat metals for shaping. Today, they serve diverse thermal processing applications in industries like automotive, aerospace, and ceramics.

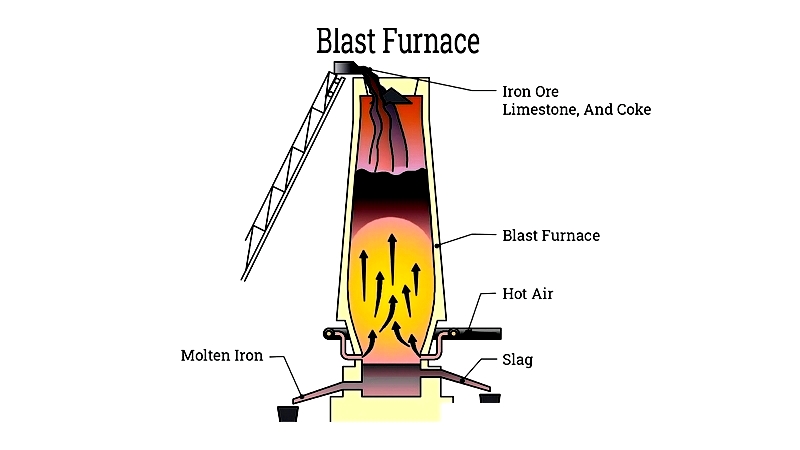

Blast Furnaces

Blast furnaces are tall, heat-resistant cylinders for high-volume metal smelting, such as extracting iron from ore. They use preheated air and gasses to produce molten iron and slag, featuring refractory linings for continuous operation. Modern blast furnaces include advanced temperature controls and energy-efficient fuel injection.

Electric Furnaces

Electric furnaces use resistance or induction heating for precise temperature control in inert or oxidizing environments. They are energy-efficient and used for steelmaking, laboratory testing, and specialty alloy melting.

Gas Fired Furnaces

Gas-fired furnaces operate on natural gas or propane, achieving high combustion efficiency. They are cost-effective for forging, foundry casting, and thermal processing, though emissions must be carefully managed.

Heat Treating Furnaces

Heat treating furnaces modify material properties through processes like hardening and annealing. They offer precise temperature control and uniform heat distribution for automotive and aerospace components.

Double Chamber Furnace

Double chamber furnaces handle sequential processes like preheating and annealing in a single operation, improving throughput and energy efficiency.

Muffle Furnace

Muffle furnaces provide contamination-free heating with sealed chambers, essential for analytical chemistry and material synthesis.

Humpback Furnace

Humpback furnaces feature raised heating sections for ultra-pure processes in electronics and powder metallurgy.

Ashing Furnace

Ashing furnaces support high-temperature oxidation for sample analysis in food, petroleum, and semiconductor industries.

Calcination Furnace

Calcination furnaces remove volatile components at high temperatures, used in cement production and ceramics.

Tempering Furnaces

Tempering furnaces improve ductility and toughness in hardened metals, crucial for tools and high-strength components.

Sintering Furnace

Sintering furnaces fuse powdered materials without melting, used in powder metallurgy and additive manufacturing.

Rotary Tube Furnaces

Rotary tube furnaces process bulk materials continuously, ideal for catalyst activation and mineral processing.

Induction Furnaces

Induction furnaces use electromagnetic heating for energy-efficient metal melting with minimal oxidation.

Vacuum Furnaces

Vacuum furnaces prevent oxidation in high-purity processes like brazing and sintering for aerospace and toolmaking.

Pit Furnace

Pit furnaces are vertical batch units for heat treating long or bulky workpieces in automotive and forging applications.

Conveyor Furnaces

Conveyor furnaces enable continuous heat treatment with high throughput for brazing and sintering operations.

Tensile Testing Furnaces

Tensile testing furnaces analyze high-temperature mechanical properties for quality assurance in aerospace and automotive industries.