Introduction

This article provides an in-depth exploration of water filtering systems.

It covers detailed information on topics including:

- Principles of Water Filtering Systems

- Types of Water Filtering Systems

- Applications and Benefits of Water Filtering Systems

- And More...

Chapter 1: Principles of Water Filtering Systems

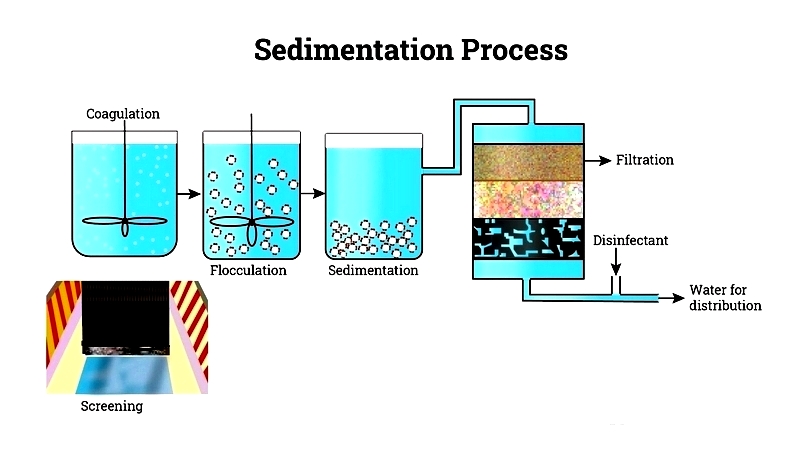

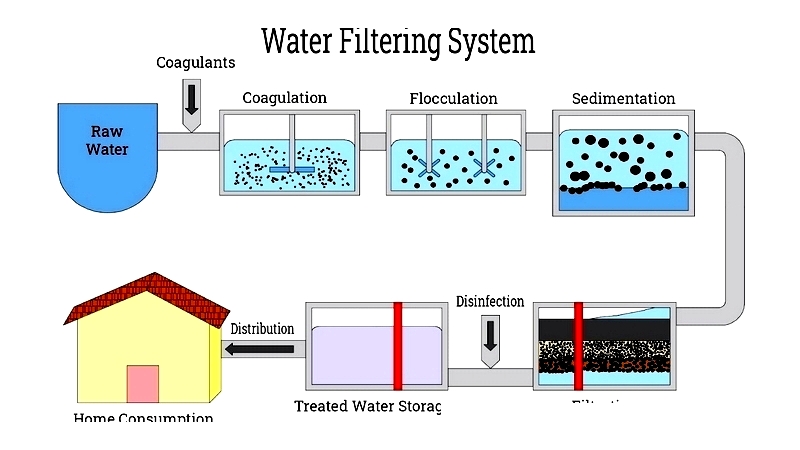

This section examines the fundamentals of water filtration systems, including their components and working mechanisms.

What is a Water Filtering System?

A basic water filtration system consists of four essential elements: a filtering medium, a liquid containing suspended solids, a driving force (typically created by pressure differences), and the filter mechanism that houses these components. The filtration process produces a byproduct called 'cake', and the system includes features to handle its removal, cleaning, and drying.

Components of a Water Filtration System

An effective water filtration system requires four key components: the filtering medium, the liquid with suspended solids, a driving force, and the filter apparatus. The process generates a 'cake' byproduct, which the system manages through specialized removal and cleaning features.

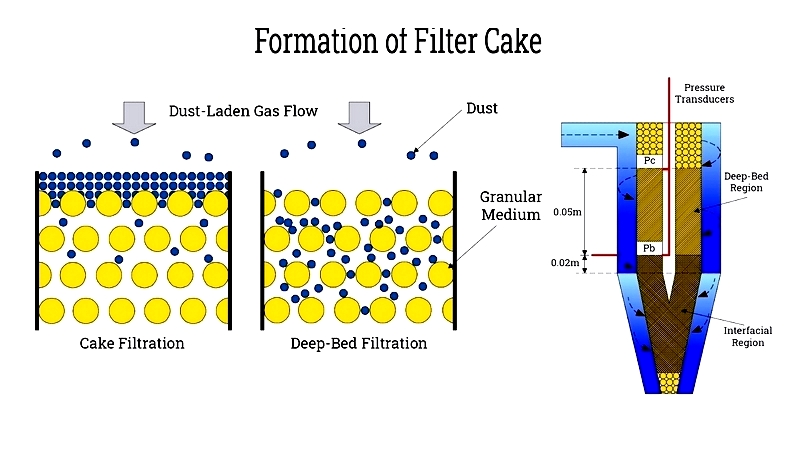

Filter media fall into two main categories: thin barriers (like filtration cloths or laboratory filter papers) and thick barriers (such as sand beds or porous ceramics). Thin media have openings smaller than the particles they filter, while thick media like sand beds can trap particles through complex pathways despite having larger pores.

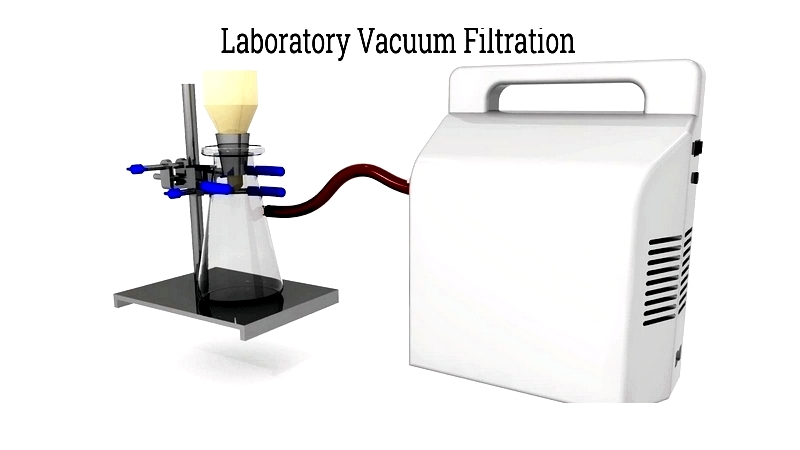

The filtering force drives liquid through the medium, created by gravity, centrifugal force, or vacuum pressure. In laboratory settings, vacuum filtration accelerates the process by applying pressure differences.

How a Water Filtering System Works

Water filtering systems typically work by trapping contaminants while allowing clean water to pass through.

Residential systems often use thin film membranes to filter microscopic bacteria. Activated carbon attracts and holds contaminants like lead, while chemical reactions reduce substances such as chlorine.

Chapter 2: Types of Water Filtering Systems

Industrial and commercial settings commonly use five main filter types, which we'll explore in this section.

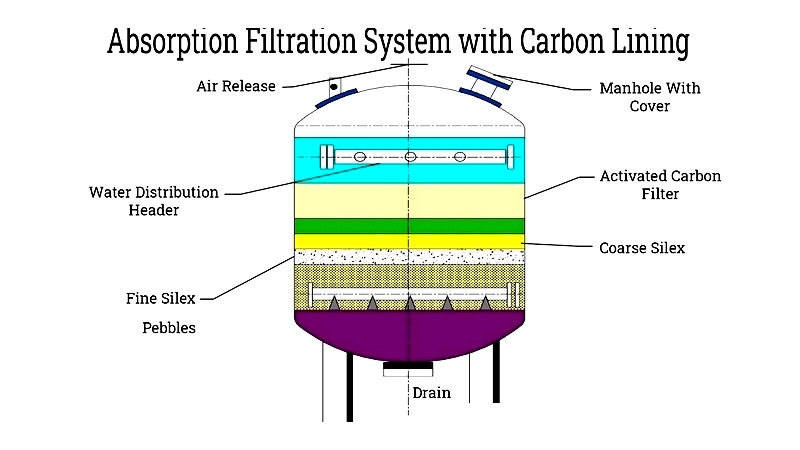

Absorption Water Filtration System

These systems typically use carbon, whose porous structure effectively traps water contaminants. Advanced models employ carbon blocks for superior filtration and precise particle removal.

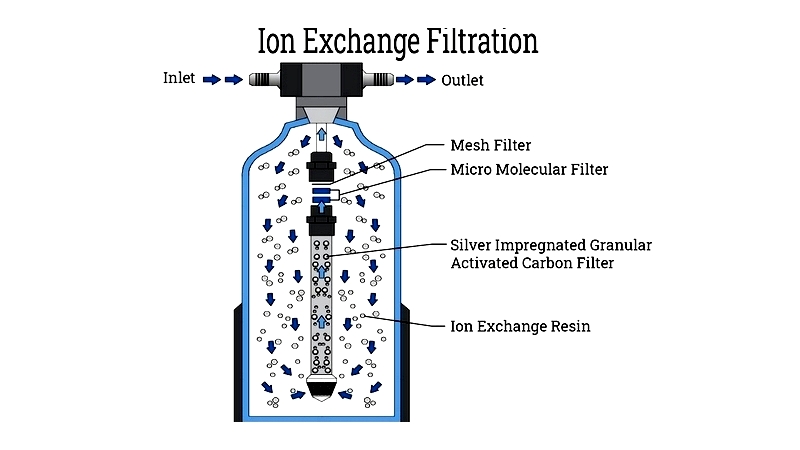

Ion Exchange Water Filtration System

This method softens hard water by exchanging magnesium and calcium ions with sodium or hydrogen ions. While effective, sodium-based resins are often avoided in drinking water due to increased salt content.

Mechanical Water Filtering System

These filters are rated by micron size, indicating their particle-removal capability:

- 5 micron – Removes visible particles

- 1 micron – Filters microscopic particles

- 0.5 micron – Removes cysts like giardia

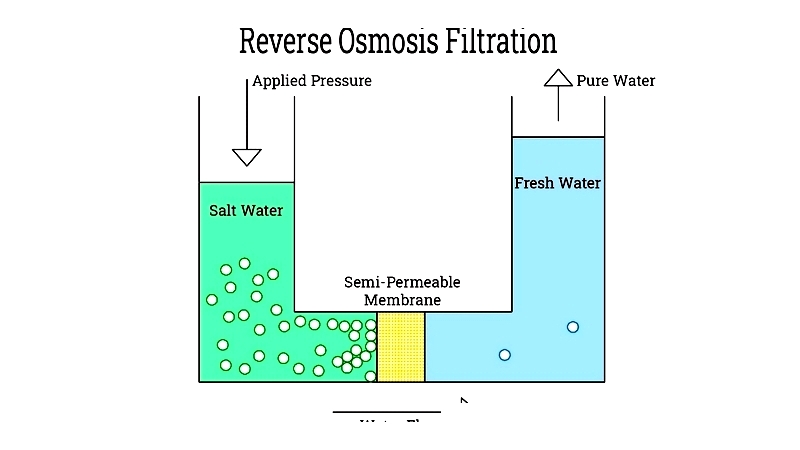

Reverse Osmosis

This process removes dissolved solids by forcing water through a semipermeable membrane. While effective, it produces wastewater and often combines with other filtration methods.

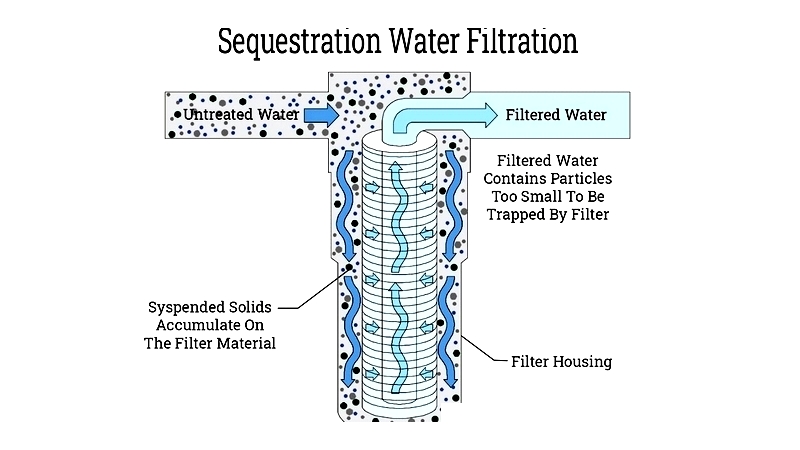

Sequestration Water Filtration System

This method chemically isolates minerals like calcium using polyphosphates, preventing scaling in hard water areas.

Typical Examples of Water Filtration Systems

Common applications include:

Coffee Machine Water Filters

Specialized filters maintain optimal mineral content for coffee flavor extraction.

Drop in Filters

These fit inside standard filter housings, commonly in 10" or 20" sizes.

Fridge Filters

Essential for purifying water in refrigerators with ice makers and water dispensers.

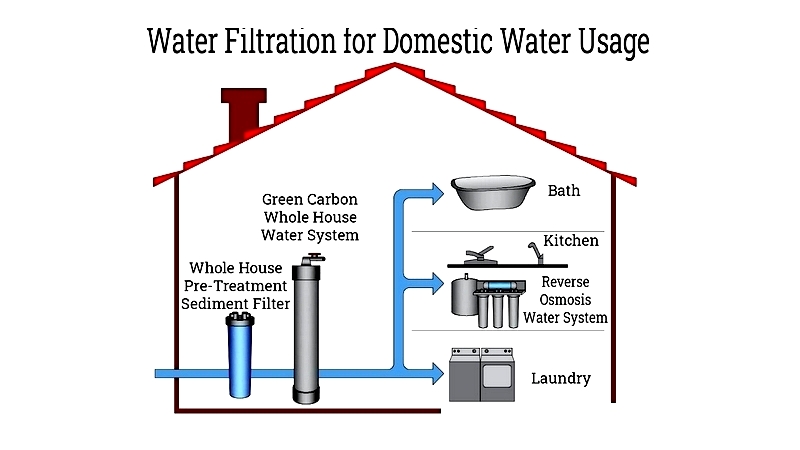

Household Water Filter Systems

Compact systems improve water taste and quality for home use, with options for under-sink installation.

Inline Water Filters

Directly installed on water lines, these compact filters improve municipal water quality.

Water Filters for Commercial Foodservice

Prevent limescale buildup in equipment like combo ovens that use steam generation.