Introduction

This article provides an in-depth exploration of Powder metallurgy.

You will learn about key topics including:

- The fundamentals of Powder metallurgy

- Different types of Powder metallurgy processes

- Parts and products manufactured through Powder metallurgy

- metals utilized in Powder metallurgy

- And much more...

Chapter One - What is Powder metallurgy?

Powder metallurgy is a manufacturing technique that produces precise components by compacting metal powders under high pressure in a fixed die. With technological advancements, it has become essential for creating bushings, bearings, gears, and various structural parts.

Sintering is fundamental to powder metallurgy's effectiveness. This process involves heating the powder just below its melting point, allowing particles to bond and form a solid structure.

Chapter Two - What are the main stages of the powder metallurgy process?

Powder metallurgy is an advanced metal forming process used for shaping both ferrous and non-ferrous metals. This technology has ancient origins but became prominent during the industrial revolution, enabling mass production of complex parts and specialized components.

Originally limited to specialized applications, powder metallurgy became widely adopted in the 20th century with electrical advancements. It now serves as a cost-effective method for producing precision parts with minimal material waste across industries like automotive, aerospace, and medical devices.

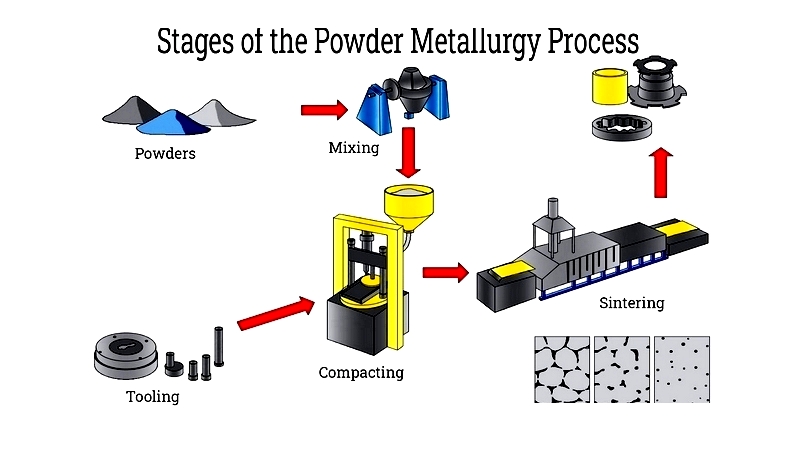

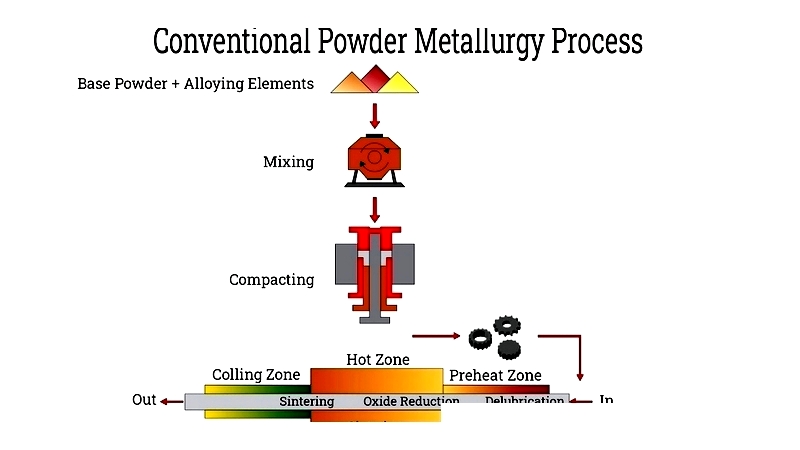

The process consists of four core stages: powder preparation, blending and mixing, compacting, and sintering. These steps, sometimes supplemented with secondary operations, produce components such as gears, bearings, and filters.

Various production methods exist, including conventional powder metallurgy, metal injection molding, isostatic pressing, and metal additive manufacturing. Each method addresses specific material properties and design requirements.

Four Basic Steps of Powder metallurgy

Powder Preparation

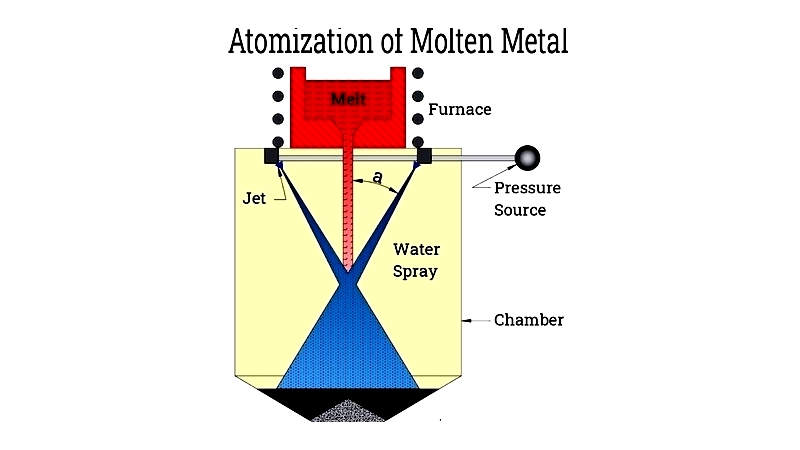

The quality of powder metallurgy parts depends significantly on the initial powder characteristics. Melt atomization is the most common production method, where molten metal forms fine droplets that solidify into particles.

Alternative techniques include chemical reduction, electrolytic deposition, mechanical grinding, and thermal decomposition. These methods process metals like stainless steel, aluminum, and titanium into suitable powders.

Powder characterization ensures material quality by analyzing particle size, flowability, density, and compressibility. These factors influence production yields and final part properties.

Mixing and Blending

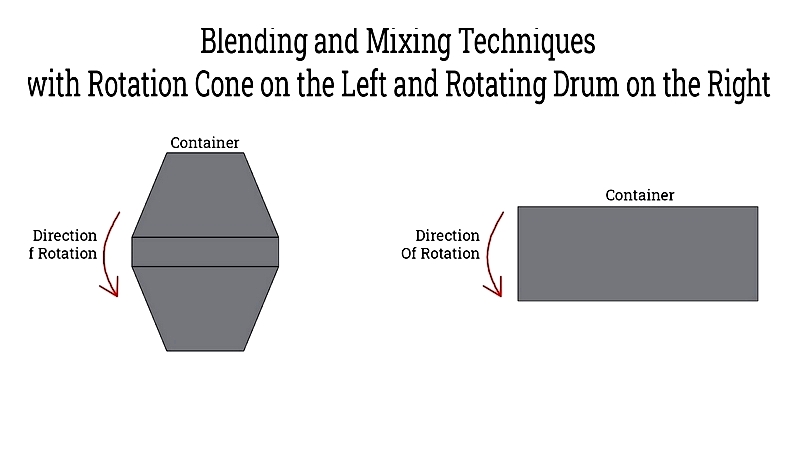

This stage combines metal powders with alloying elements, binders, and lubricants to achieve desired properties. Proper blending ensures material homogeneity and enhances mechanical characteristics.

Primary blending techniques include rotating drums, double cones, screw mixers, and blade mixers. The method selection depends on part geometry and powder characteristics.

Compacting

Compacting transforms blended powders into "green compacts" through high-pressure forming in rigid dies. This step determines the part's shape, density, and mechanical performance.

Pressure requirements vary by material, ranging from 100 MPa for softer metals to 700 MPa for harder alloys. Advanced presses ensure dimensional accuracy for industrial applications.

Sintering

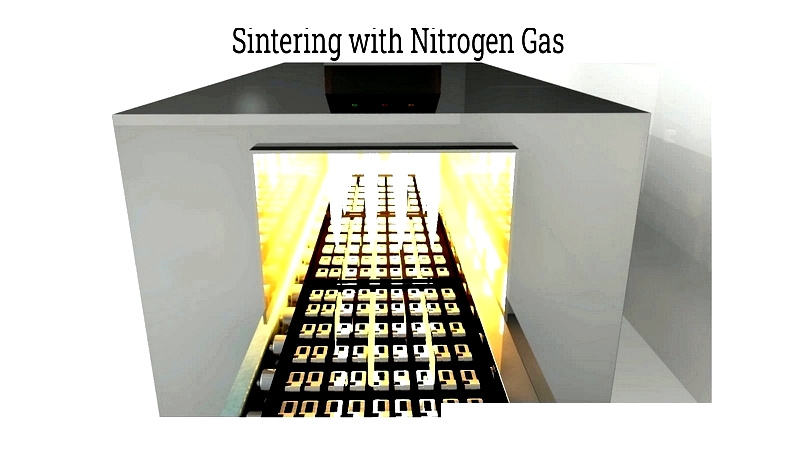

Sintering strengthens green compacts through controlled heating below melting temperatures. This process creates metallurgical bonds between particles, producing dense, durable parts.

Atmosphere control during sintering enhances properties like hardness and wear resistance. Additional finishing processes may follow to improve tolerances and surface quality.

Powder metallurgy Processes

Conventional

Conventional powder metallurgy delivers cost-effective, high-volume production of components with excellent dimensional accuracy. Common applications include automotive parts and industrial components.

Injection Molding

metal injection molding excels at producing complex, miniature parts. This method combines fine metal powders with binders for injection molding, followed by debinding and sintering.

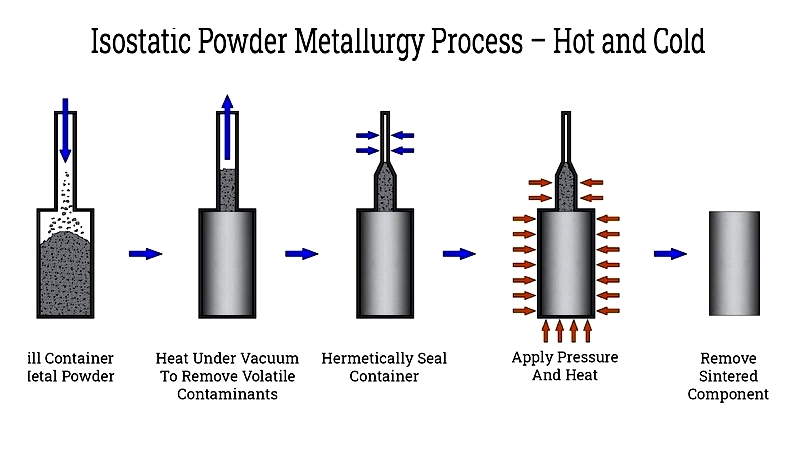

Isostatic Pressing

Isostatic pressing applies uniform pressure from all directions, creating parts with exceptional density. It includes:

- Cold Isostatic Pressing (CIP): Shapes large or fragile components at room temperature.

- Hot Isostatic Pressing (HIP): Combines heat and pressure for high-performance applications.

metal Additive

metal additive manufacturing builds parts layer by layer from metal powders using 3D printing technologies. This method enables complex geometries and rapid prototyping for aerospace and medical applications.