Introduction

This article provides a comprehensive overview of AC power supplies.

Continue reading to explore key topics including:

- Understanding AC power supplies

- The nature of Alternating Current

- Single-Phase and Three-Phase AC Power Systems

- AC to AC conversion technology

- Power inverter applications

- Uninterruptible power supply (UPS) systems

- AC power adapters

- Programmable Power Supply units

- And additional related topics

Chapter 1: Understanding AC Power Supplies

An AC power supply is a specialized electrical device that delivers alternating current to connected equipment. It can process input power in either AC or DC formats. Since standard mains electricity and certain power storage systems often don't meet specific device requirements, AC power supplies perform essential conversion and regulation functions. These units transform voltage levels and filter the output to provide precise, controlled electrical power that matches the exact voltage, current, and frequency needs of the connected load.

Furthermore, AC power supplies can adjust output voltage while maintaining safe current limits for connected devices.

Chapter 2: The Fundamentals of Alternating Current

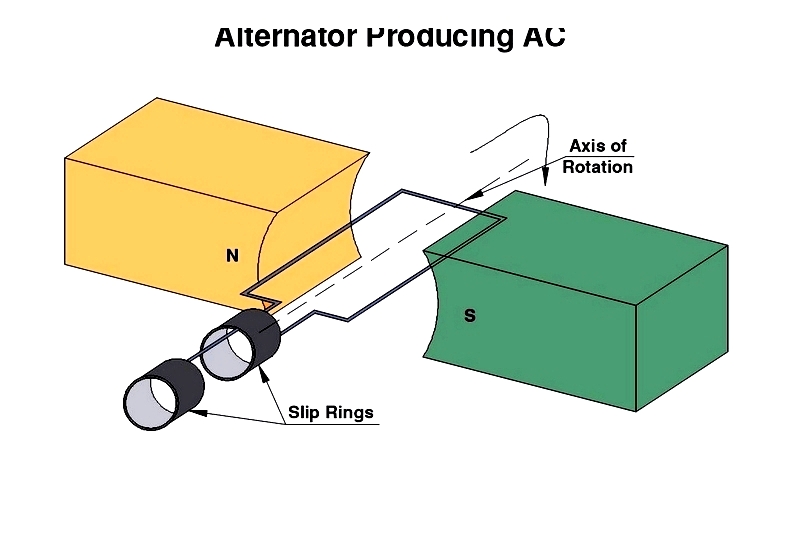

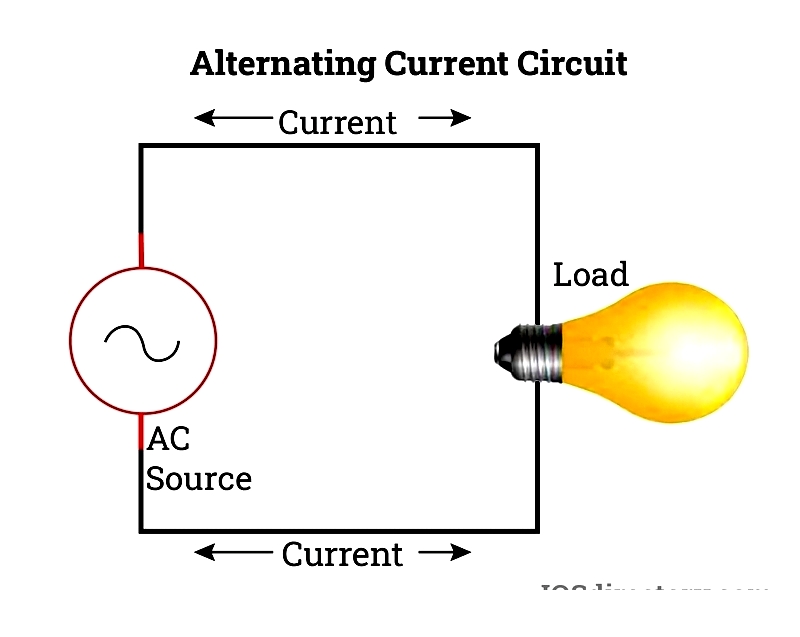

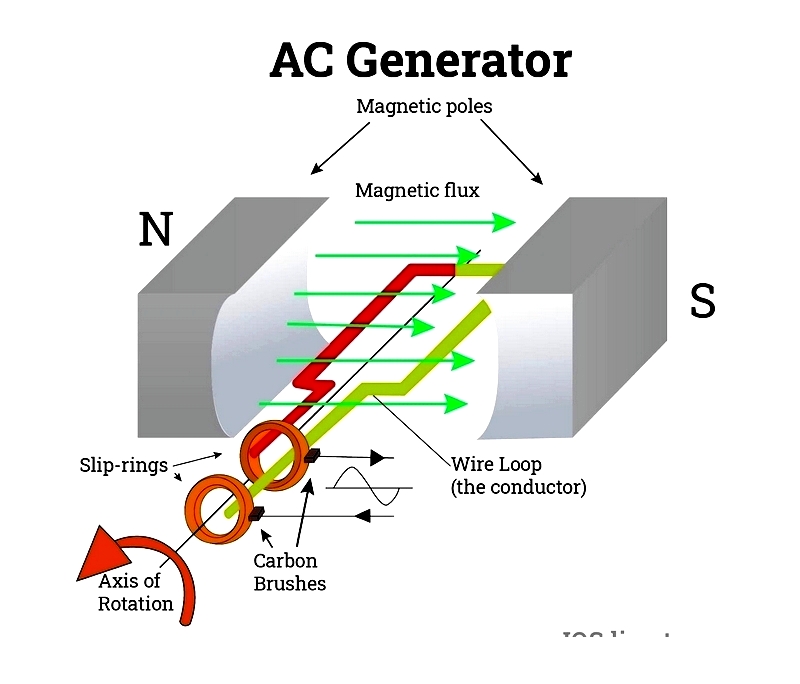

Alternating current (AC) represents a cornerstone of electrical engineering and power distribution systems. Unlike direct current (DC) which flows consistently in one direction, AC periodically reverses its flow direction, causing voltage polarity to alternate over time. This characteristic behavior results from electromagnetic induction in AC generators, where rotating conductors (rotors) interact with stationary magnetic fields (stators) to produce alternating voltage and current.

AC differs fundamentally from direct current (DC), where current maintains constant direction and polarity. While DC powers battery-operated devices, AC dominates electrical grid distribution due to its superior transmission efficiency and transformer compatibility.

AC Waveform Characteristics

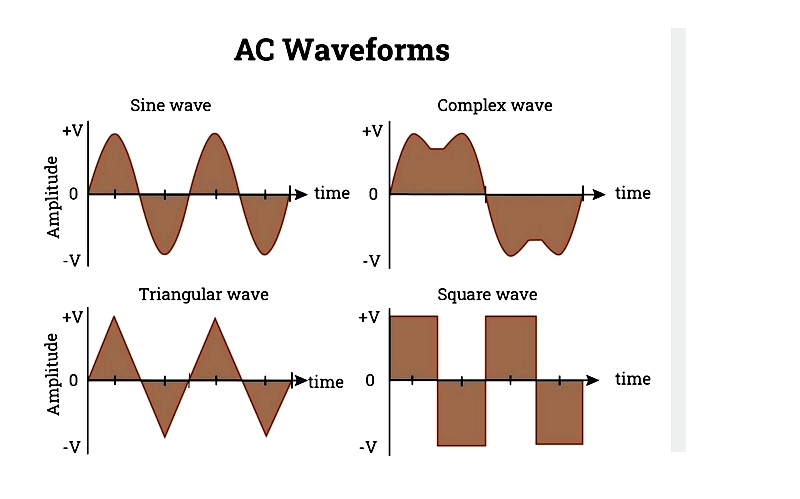

Electrical waveforms graphically represent current or voltage variations over time. AC waveforms display instantaneous values through periodic oscillations, with the sinusoidal waveform (or sine wave) being the most prevalent due to its smooth, repetitive pattern and energy efficiency. Other waveform types like triangular, square, and sawtooth find applications in specialized circuits including signal processing and power conversion systems.

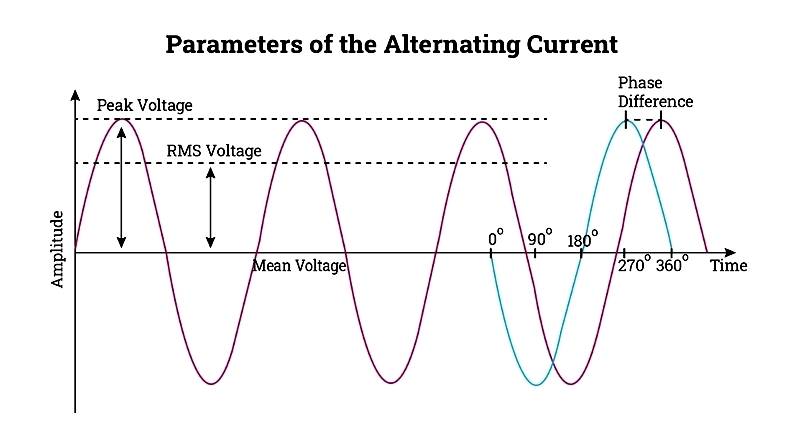

Sine waves feature continuous, symmetrical oscillations around a zero baseline, forming characteristic S-shaped curves. When plotted, the horizontal axis represents time (measured in degrees or seconds), while the vertical axis indicates voltage or current magnitude. Each complete cycle spans 360° (or 2π radians) of rotation.

The mathematical expression for an AC sine wave is: A(t) = Amax sin (2πft), where Amax denotes amplitude, f represents frequency, and t indicates time.

Several critical AC parameters derive from sinusoidal waveforms, influencing electrical measurement and application across various fields:

- Amplitude (Amax) indicates the maximum voltage or current value achieved during each cycle, corresponding to waveform peaks at 90° and troughs at 270°. Negative trough values signify reversed current direction rather than negative magnitude. The highest voltage point is termed "peak voltage".

- Frequency (f) measures cycle repetitions per second in Hertz (Hz), determining oscillation speed and serving as a fundamental specification for AC power systems and device synchronization.

- Period (T) defines the duration of one complete cycle, inversely proportional to frequency (T = 1/f).

- Mean values represent cycle averages, typically zero for symmetrical AC waveforms unless modified by DC offset components.

- Root-mean-square (RMS) values provide equivalent DC measurements for power calculation purposes, essential for rating electrical equipment. For sine waves, RMS equals peak value divided by √2.

- Phase difference (φ) measures angular separation between multiple waveforms, critical for three-phase systems, motor operation, and power factor management.

Alternating Current Applications

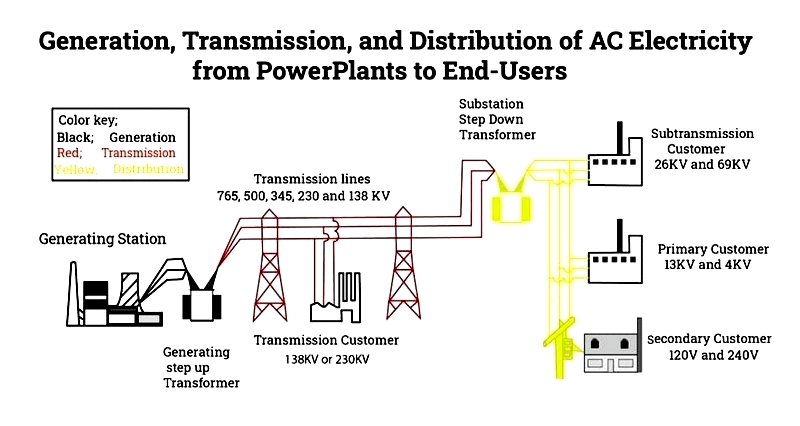

AC power forms the backbone of contemporary electrical infrastructure. Virtually all power generation facilities—whether fossil fuel, nuclear, or renewable—produce and distribute electricity as AC through national grids. AC's voltage transformation capability enables efficient long-distance transmission with minimal energy loss, facilitated by transformers that exclusively operate with alternating current.

AC directly powers numerous household appliances and industrial equipment, including lighting systems, climate control units, electric motors, and refrigeration systems. While AC dominates power distribution, DC power remains vital for portable electronics, requiring AC-DC conversion through adapters or rectifiers.

Global AC power standards vary, with North America typically using 60 Hz/120V systems and many other regions operating at 50 Hz/220-240V. These differences necessitate careful consideration when using electrical devices internationally to prevent equipment damage.

Specialized AC power equipment like voltage converters, frequency changers, and power conditioners ensures compatibility between devices and local power standards. Maintaining proper power quality and voltage levels proves essential for safe, efficient operation of electrical systems and sensitive electronics.

As renewable energy adoption grows, modern power systems increasingly incorporate advanced AC technologies such as grid-tie inverters, power storage systems, and smart grid components. These innovations demonstrate AC power's continued relevance in our evolving energy landscape, ensuring reliable electricity delivery for residential, commercial, and industrial applications worldwide.