Introduction

This article provides an in-depth exploration of plastic gears.

Key topics covered include:

- What are Plastic Gears?

- Plastic Gear Design

- Materials Used for Plastic Gears

- Types of Plastic Gears

- Advantages and Disadvantages of Plastic Gears

- And more...

Chapter 1: How are plastic gears manufactured?

This section explores plastic gears, focusing on their manufacturing processes and operational applications.

What are Plastic Gears?

Plastic gears are toothed wheels crafted from advanced engineering plastics, primarily used to adjust speed ratios between motors and connected components. Common materials include nylon (a polyamide resin) and polyacetal.

Methods of Manufacturing Plastic Gears

Plastic gear production shares similarities with metal gear manufacturing, differing primarily in material properties. Each gear's design is application-specific, influencing production techniques. While plastics lack metal's strength and are more temperature-sensitive, they offer advantages in shock absorption and vibration damping.

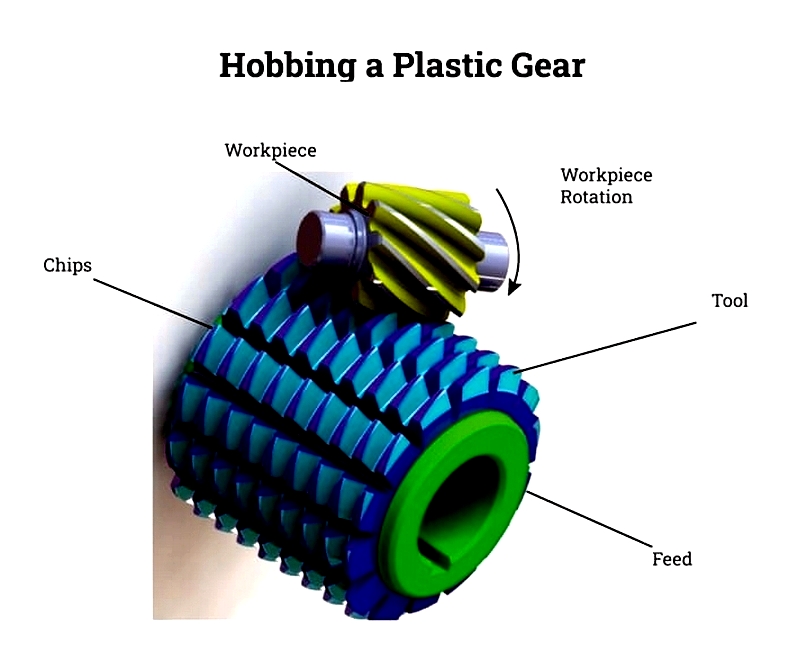

Plastic Gear Hobbing

This process uses a toothed cylindrical tool (hob) to cut gear teeth into plastic disks. Adjusting the hob's contact angle creates different gear types. Hobbing is cost-effective for producing precise spur gears, helical gears, and sprockets.

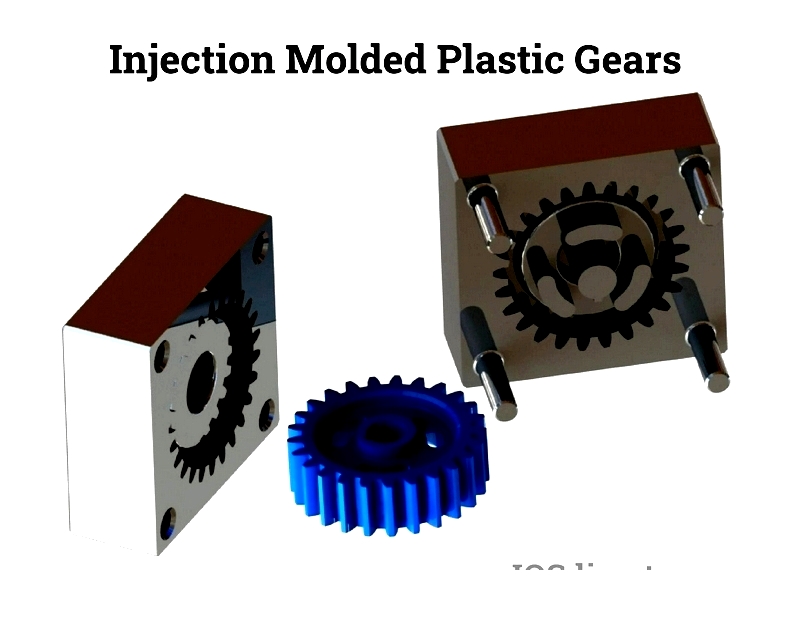

Injection Molding

Steel molds shape molten plastic under pressure to create gears with precise dimensions. While initial costs are high, this method excels in large-scale production.

Characteristics of Injection Molded Gears

- High precision

- Excellent replication

- Cost-effective at scale

- Wear-resistant

- Non-corrosive

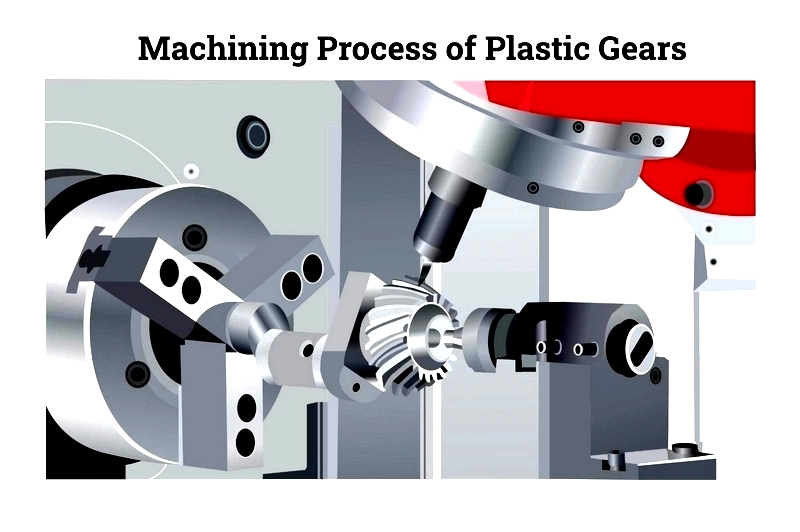

CNC Machining of Plastic Gears

CNC machining offers flexibility in producing various gear types by removing material from plastic stock. While precise, it's generally slower and more expensive than other methods for high-volume production.

Characteristics of CNC Machined Plastic Gears

- Lightweight

- Low maintenance

- Vibration damping

- Quiet operation

- Self-lubricating

Differences between Machining and Injection Molding

Production Speed

Machining suits small batches, while injection molding excels in mass production after initial setup.

Cost Considerations

Machining is economical for hundreds of parts; injection molding reduces per-unit costs at scale.

Material Options

Machining accommodates stronger plastics; injection molding typically uses softer, moldable materials.

Precision Levels

CNC offers tighter tolerances; injection molding may introduce minor defects but ensures consistency.

Design Flexibility

Injection molding excels in repeatability; machining allows easier design modifications.

Chapter 2: Leading Plastic Gear Machine Manufacturers

Plastic gear manufacturing serves diverse industries with benefits including lightweight design, corrosion resistance, and cost efficiency. Key manufacturers offer specialized equipment for precision gear production.

Arburg - Allrounder Series

Known for modular injection molding machines with high precision and energy efficiency, ideal for various plastic gear types.

Engel - Victory Series

Features tie-bar-less designs and servo-electric drives for precision gear molding, particularly in automotive and medical sectors.

Sumitomo (SHI) Demag - IntElect Multi Series

Specializes in multi-component gear production with ultra-high-speed operation and advanced automation.

Milacron - Elektron Multi-Shot Series

Excels in multi-material gear molding with integrated robotics for high-efficiency production.

Nissei - NEX Series

Offers high-speed, energy-efficient machines for precision gear manufacturing across industries.

Chapter 3: Plastic Gear Design and Materials

Effective gear design considers torque requirements, rotational speeds, environmental conditions, and material properties to ensure optimal performance.

Design Considerations

Gear Face Width

Width impacts strength and durability, particularly in high-load applications.

Gear Module

Determines gear size and compatibility within drive systems.

Pressure Angle

Affects tooth strength and load distribution, with modern designs favoring 20° or higher angles.

Backlash Management

Critical for reducing noise and vibration in precision applications.

Temperature Considerations

Material selection must account for operational heat to prevent deformation.

Material Options

Polyacetal (POM)

Offers high stiffness and low friction for precision applications.

Polyphenylene Sulfide (PPS)

Excels in high-temperature environments with excellent chemical resistance.

Nylon

Provides toughness and wear resistance with inherent noise reduction.

Polycarbonate

Combines impact strength with dimensional accuracy for specialized applications.

Polyurethane

Delivers elasticity and chemical resistance for low-maintenance solutions.