Introduction

This article provides an in-depth exploration of linear rails.

It covers detailed information on various aspects including:

- Principles of Linear Rails

- Types of Linear Rails

- Applications and Benefits of Linear Rails

- And More...

Chapter 1: Understanding the Fundamental Principle of Linear Rails

This chapter examines the core concepts of linear rails, focusing on their structural design and operational mechanics.

Defining Linear Rails

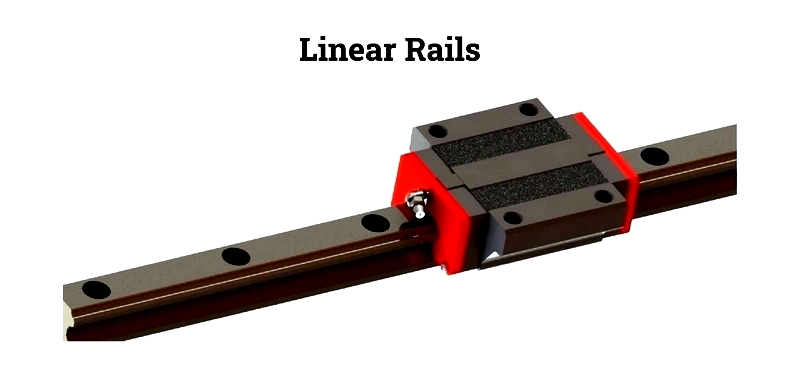

Linear rails play a crucial role in manufacturing by enabling precise transportation of items with minimal friction. They are widely used in fabrication, packaging, and distribution across various industries.

These systems efficiently manage equipment movement and weight in both vertical and horizontal directions, ensuring smooth product relocation during production and packaging.

Also known as linear guide rails, linear guides, or linear slides, they facilitate load transfer along specified paths with low friction.

Typically made from high-strength, corrosion-resistant steel, linear rails undergo cold drawing before receiving roller runners. Profiled rail guides are ideal for heavy loads, providing accurate linear motion in various sizes.

Design Elements of Linear Rails

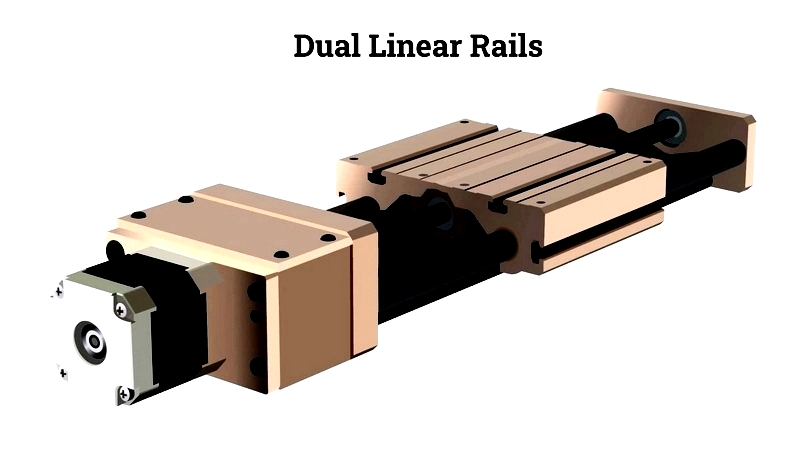

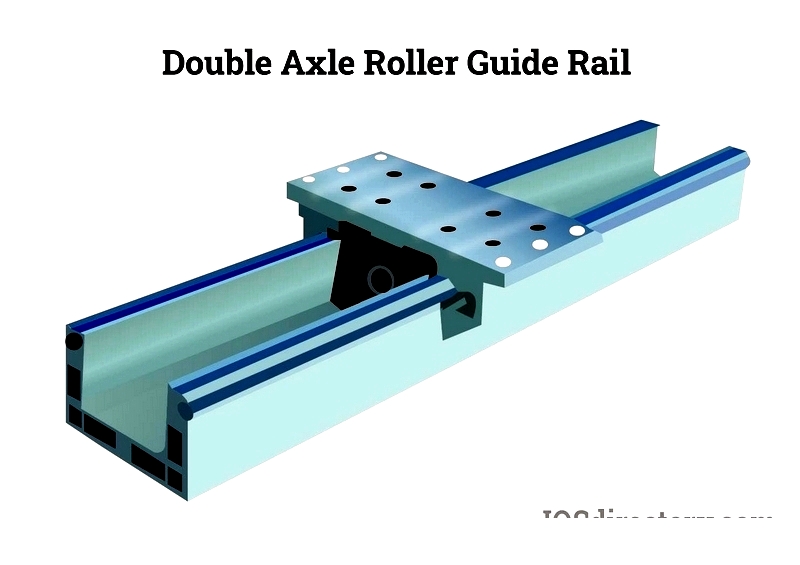

Linear rails vary in length from short segments to over 2 meters, customized for specific uses. The industry primarily uses two types: ball bearing runners and roller runners. The system consists of a rail and runner, with recirculating balls or roller bearings for smooth movement.

Linear Rail Bearings

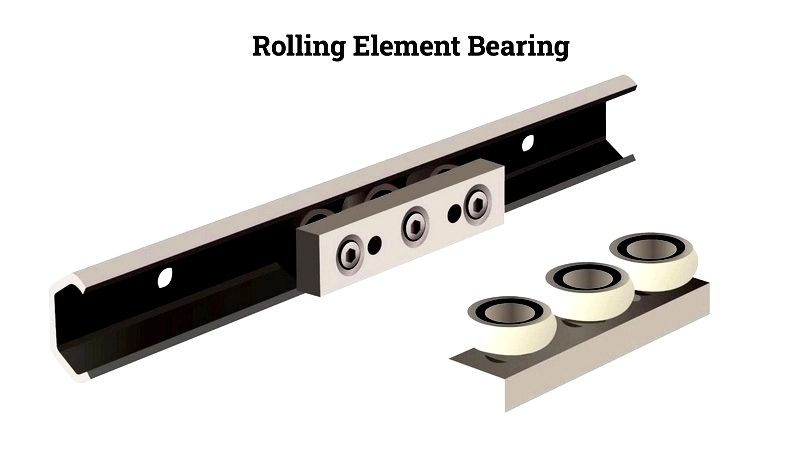

Linear slides utilize different bearings, including rolling element, ball, and roller bearings, as well as plain surface bearings with various lubrication methods. Magnetic bearings are also used in some systems.

Rolling element bearings are most common due to their durability and versatility, while magnetic and hydrostatic bearings serve specialized applications.

Recirculation methods distinguish rolling element bearings. Non-recirculating systems limit travel to the rolling element row length, while recirculating systems allow continuous movement with ball bearings often used.

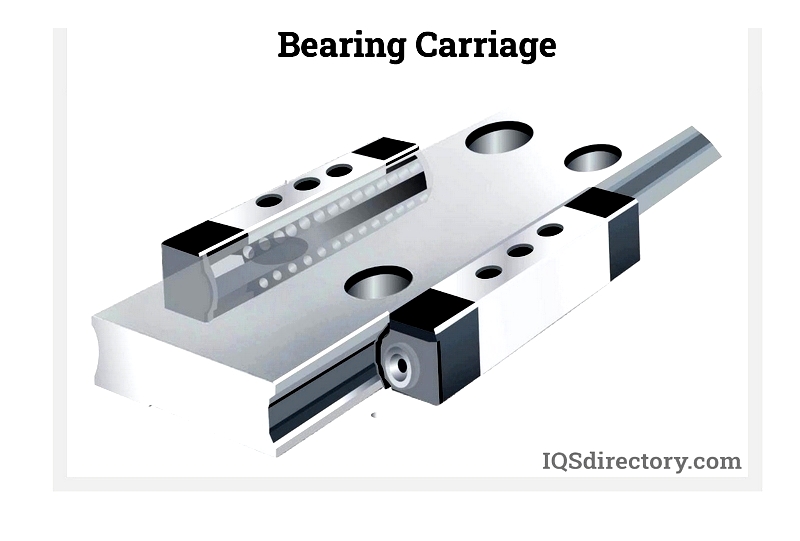

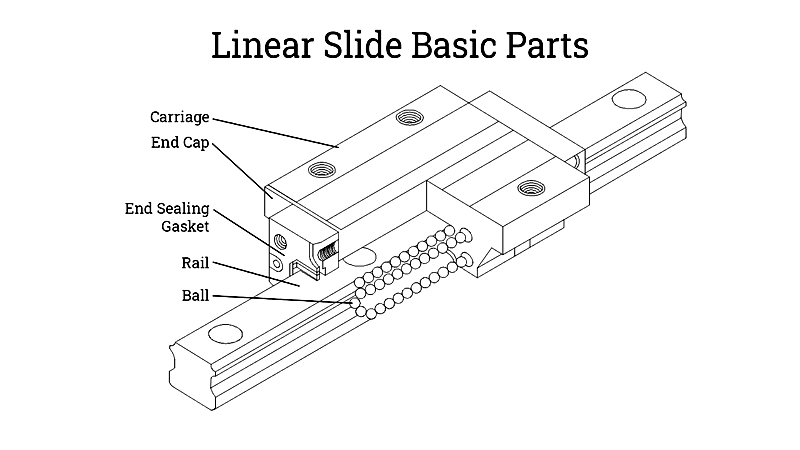

Linear Rail Carriage

The carriage moves along bearings, supporting instruments in the X-Y plane.

Power screws or drive systems enable Z-axis movement, with the carriage typically connected to a drive unit.

Guide Rail

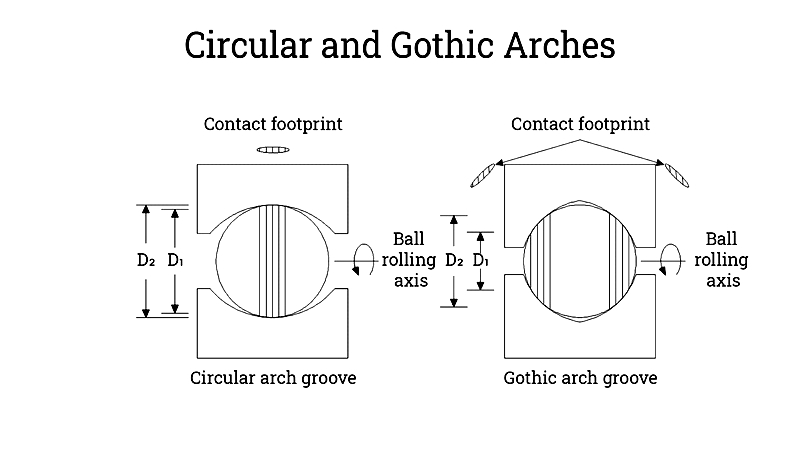

These surfaces work against fixed components in systems using plain or rolling element bearings. Guide rails may be flat or shaped as shafts, with race designs balancing contact surface and stress.

Circular arch profiles are preferred for consistency, while gothic arches offer higher load capacity but increased friction.

End Cap

In recirculating systems, end caps guide rolling elements back to the return path for continuous motion.

Lubrication Port

End caps include lubrication features to maintain smooth operation and extend bearing life.

Rail Seals

Seals protect bearing races from contaminants like dirt and metal debris that could cause damage.

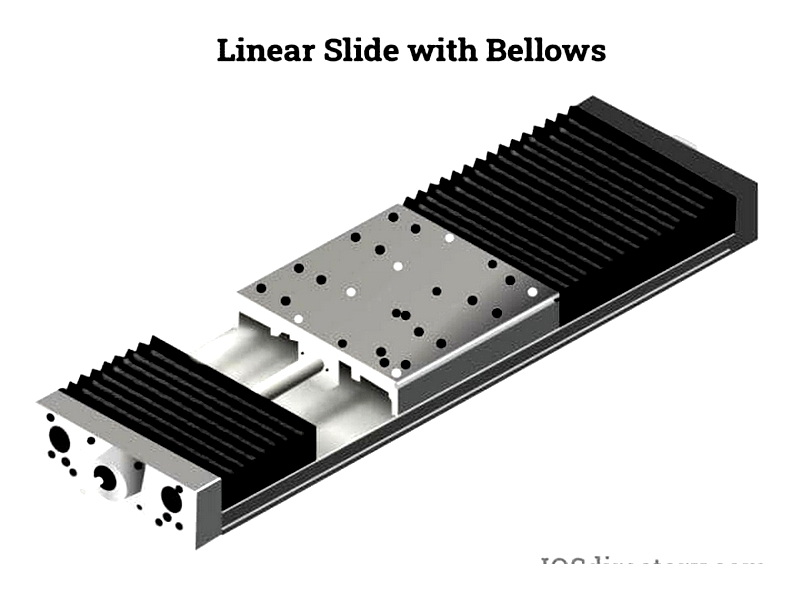

Bellows and Covers

Protective covers shield guide rails from damage in environments with metal chips or abrasive materials.

Impact Dampers

Positioned at carriage ends, these prevent damage from excessive travel.

Control System

For slides with drive units, control systems manage carriage movement through operator controls or sensor feedback.

Drive Unit

Drive units provide the force to move the carriage, using ball screws, toothed belts, or pneumatic systems.

Position Sensors

Sensors ensure the carriage stays within its range and precisely locates its position.

Specifications of Linear Rails

This section covers key linear rail specifications.

Number of Axes

Systems may operate on single or multiple axes, with three-axis systems using orthogonal movement.

Side Accuracy

Accuracy depends on the bearing system, with linear bearings ensuring high precision.

Linear Travel

This refers to the total movement distance from one end to the other.

Load Capacity

The maximum load a slide can handle without damage.

Linear Speed

The highest speed at which the carriage can move.

Load, Stiffness, and Moment Ratings

These depend on the slide's design and bearing system.

Drive Mechanism Type

Ball screw drives suit high-precision applications, while pneumatic drives work for quick actions.

Operating Specifications

Proper lubrication is essential, with cleanroom applications requiring FDA-approved lubricants. Seals maintain cleanliness and may need corrosion-resistant materials in harsh environments.

Role of Linear Rails

Linear rails support and guide moving elements in reciprocating motion. They are categorized by friction characteristics.

Automation machinery uses linear bearings with steel balls for high-speed, low-friction movement, though excessive preloading may increase resistance.

Linear Rail Durability and Lifespan

Designers often question linear rail longevity, which depends on load and bearing capacity.

Theoretical life is measured in travel distance, calculated using dynamic load capacity and bearing load.

- L = Nominal Life (100km for linear rails)

- C = Dynamic load capacity (N)

- F = Bearing load (N)

- p = Exponent (3 for ball bearings, 3.33 for rollers)

This calculation is based on Hertz impact theory but doesn't fully predict real-world lifespan. Modified calculations account for survival probability.

Environmental conditions and installation practices significantly affect lifespan.

Chapter 2: Types of Linear Rails

Linear rails are essential for modern automation, enabling precise linear movement in industrial systems. Various configurations address specific needs, with some dominating due to performance and versatility.

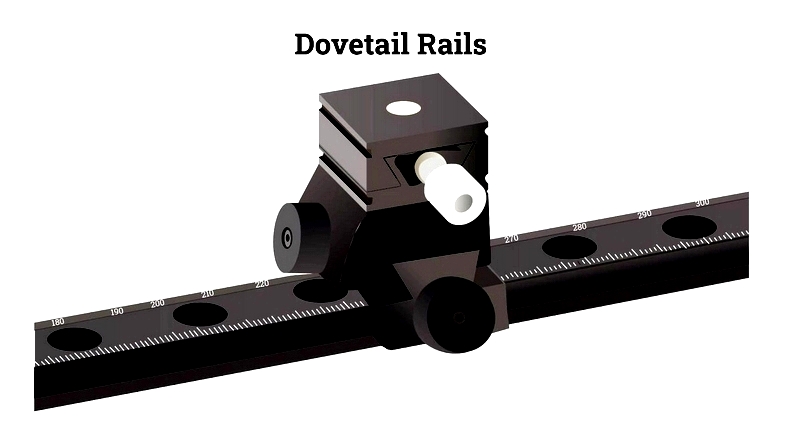

Dovetail Rails

These feature surface bearings requiring lubrication, with a dovetail-shaped projection for stable motion.

Robust and vibration-resistant, they're used in heavy-duty machine tools.

Boxway Rails

Similar to dovetail rails but with a box-shaped gib for greater load support.