Introduction

This article provides an in-depth examination of mass flow meters and their applications.

You will explore key topics including:

- What is a Mass Flow Meter?

- How Mass Flow Meters Work

- Different Types of Mass Flow Meters

- Types of Readings from Mass Flow Meters

- And more...

Chapter One – What is a Mass Flow Meter?

A mass flow meter measures gas flow rates by evaluating heat transfer across the gas surface, utilizing temperature sensors and electric heaters either inside or outside the flow path. In contrast, inertial flow meters calculate fluid mass flow rates as they pass a fixed point over time.

These devices are known by various industry terms like flow gauge, flow indicator, liquid meter, and flow rate sensor. Their superior accuracy and precision have made them the preferred choice over other flow measurement methods.

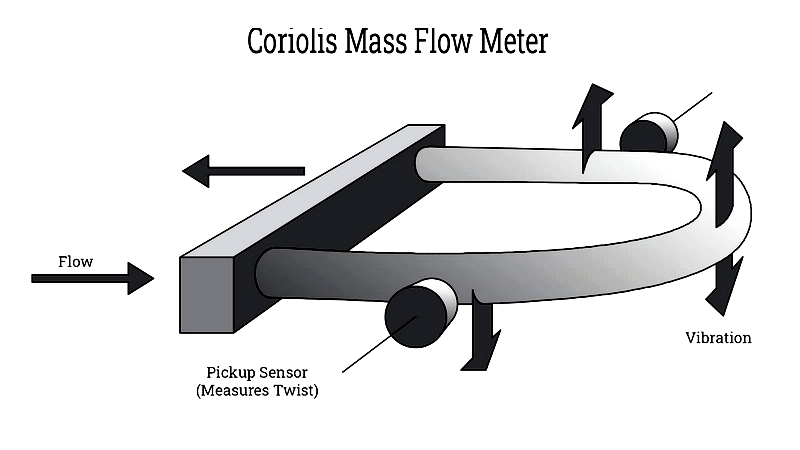

Multiple technologies exist for mass flow measurement, including Coriolis, inertial, and thermal methods. Coriolis flow meters apply the Coriolis effect, where moving mass in a rotating system generates a perpendicular force. These meters detect inertial forces from gas moving through vibrating tubes, using sensors to measure oscillation characteristics for flow evaluation.

Thermal mass flow meters rely on heat transfer principles, employing heating elements and temperature sensors. As gases flow past these sensors, they absorb thermal energy, enabling flow rate determination.

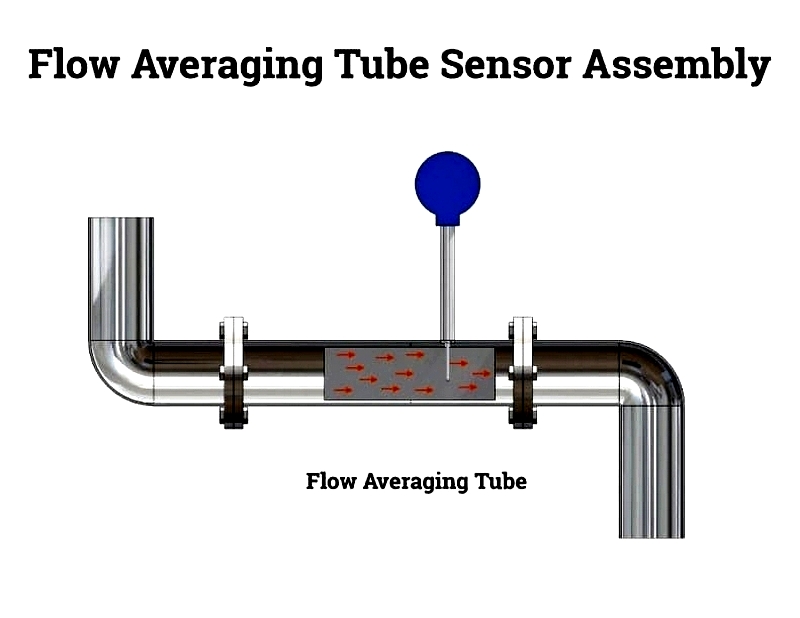

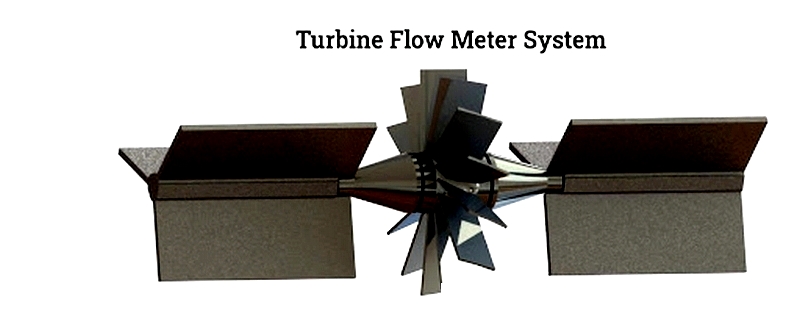

The image above shows a typical mass flow meter installation within a pipe for flow measurement.

Manufacturers equip mass flow meters with integrated temperature, pressure, and flow sensors. These devices calculate mass flow using electronics based on the formula: mass flow equals density multiplied by volumetric flow rate and cross-sectional area. Density is derived from pressure and temperature readings, while velocity is measured using turbines or vortex sensors.

Accurate flow measurement is crucial for maintaining process conditions, affecting production efficiency and product quality. In some cases, flow measurements also serve as process efficiency indicators.

Chapter Two – How Does a Mass Flow Meter Work?

Mass flow meters are essential in modern industry, providing precise flow rate measurements for liquids and gases. While all measure flow rates, each type employs different principles based on substance, conditions, and required accuracy. Common types include Coriolis, thermal, and differential pressure (DP) meters, each suited to specific applications.

In industrial settings, accurate flow measurement is vital for process control, resource optimization, and quality maintenance. These meters provide real-time flow data, supporting functions like batching, mixing, and fuel monitoring. Continuous measurement helps maximize efficiency, reduce waste, and ensure regulatory compliance.

Engineers prefer mass flow meters for their ability to automatically account for media variations like viscosity, density, or temperature changes that affect volumetric meters. This makes them ideal for industries requiring tight tolerances (±1%), including petroleum, chemical processing, food production, and pharmaceuticals.

Below is an overview of common industrial flow meters, their operating principles, strengths, and applications.

Direct Mass Flow Measurement

Direct methods eliminate inaccuracies from fluid property fluctuations. Unlike volumetric meters, they provide absolute values unaffected by pressure, temperature, or density changes. This makes them valuable for critical processes in oil & gas, pharmaceuticals, and chemical manufacturing.

Volumetric devices require strict condition maintenance for accuracy. Traditional types like turbine meters can't compensate for variable conditions, making direct mass flow meters preferable for precision applications.

Coriolis Principle

The Coriolis effect describes how moving mass in rotation creates a perpendicular force. Coriolis meters use this principle for highly accurate measurements. They contain vibrating tubes that twist proportionally to mass flow rate.

This twist is measured to generate a linear output signal. These versatile meters handle liquids, gases, and viscous fluids, making them useful for fuel dispensing, chemical injection, and food processing. They can also measure fluid density and detect multi-phase flow.

Known for high accuracy and robustness, Coriolis meters are preferred where precise measurement is critical for quality or safety.

Indirect Mass Flow Measurement

Indirect methods determine mass flow through related measurements when direct measurement isn't practical. This typically combines volumetric meters with pressure/temperature sensors and flow computers.

Common in compressed air, natural gas, and steam systems, these methods require accurate compensation algorithms and regular calibration. They offer reliable alternatives when direct measurement isn't feasible.

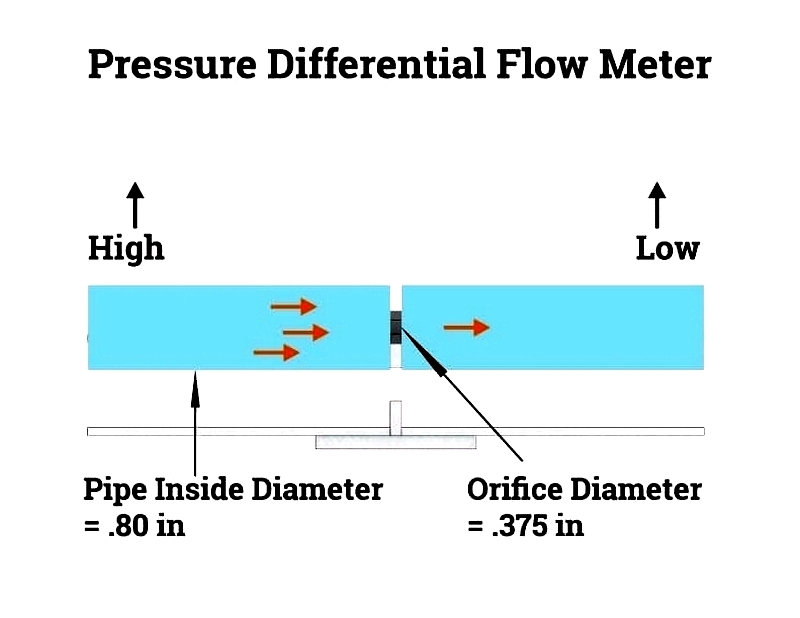

Differential Pressure (DP) Methods

DP meters, based on Bernoulli's principle, measure flow by creating pressure drops through constrictions. They're valued for simplicity and compatibility with various media.

Modern versions use multiple orifices for enhanced precision in critical applications. Proper installation and calibration are essential for accurate measurements.

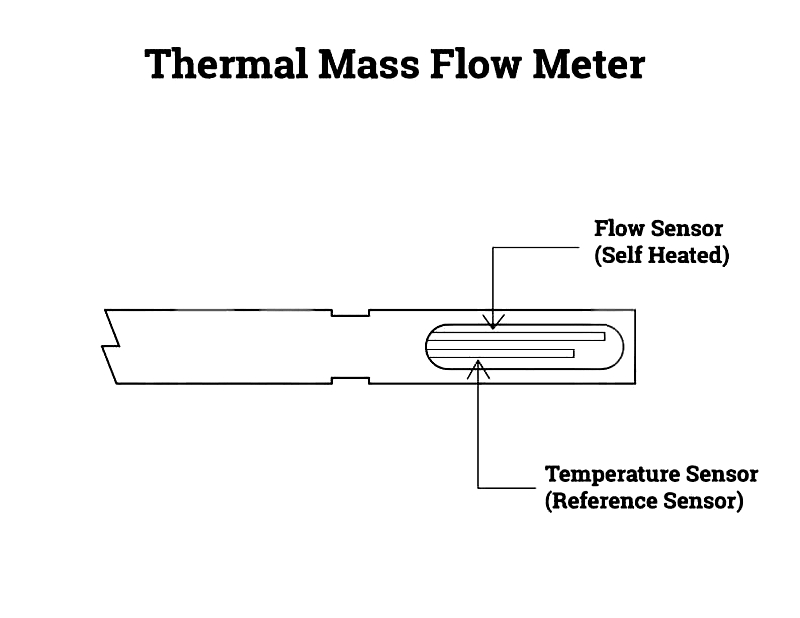

Thermal Mass Flow Meter

These specialized instruments measure gas flow by quantifying heat transfer. They use two RTDs - one heated, one reference - to calculate mass flow from temperature changes.

Unaffected by gas composition changes, they're ideal for air, natural gas, and other industrial gases. Their design suits large pipes for environmental monitoring and process control.

Turbine Measurement

Turbine meters measure flow via rotor blades turned by fluid velocity. Widely used in petroleum and water treatment, they offer robust mechanical measurement.

Advanced designs reduce wear and enable bidirectional flow measurement. Proper installation is crucial for maintaining accuracy.

How to Choose the Right Mass Flow Meter

Selection depends on fluid type, flow range, operating conditions, accuracy needs, and budget. Coriolis and thermal meters suit complex conditions, while DP or turbine meters may be better for large-scale applications.

Consult manufacturers and experts to match instruments to your needs. Consider certifications, standards compliance, and support services. Accurate measurement enhances efficiency, quality control, and regulatory compliance.

Research options from leading suppliers and use available tools to compare products based on specifications and total cost.