Introduction

This article provides an in-depth understanding of vacuum forming.

You will learn about:

- What vacuum forming is

- Materials used in vacuum forming

- Machines used in vacuum forming

- Types of products made through vacuum forming

- Advantages and disadvantages of vacuum forming

- And much more...

Chapter 1: What Is Vacuum Forming?

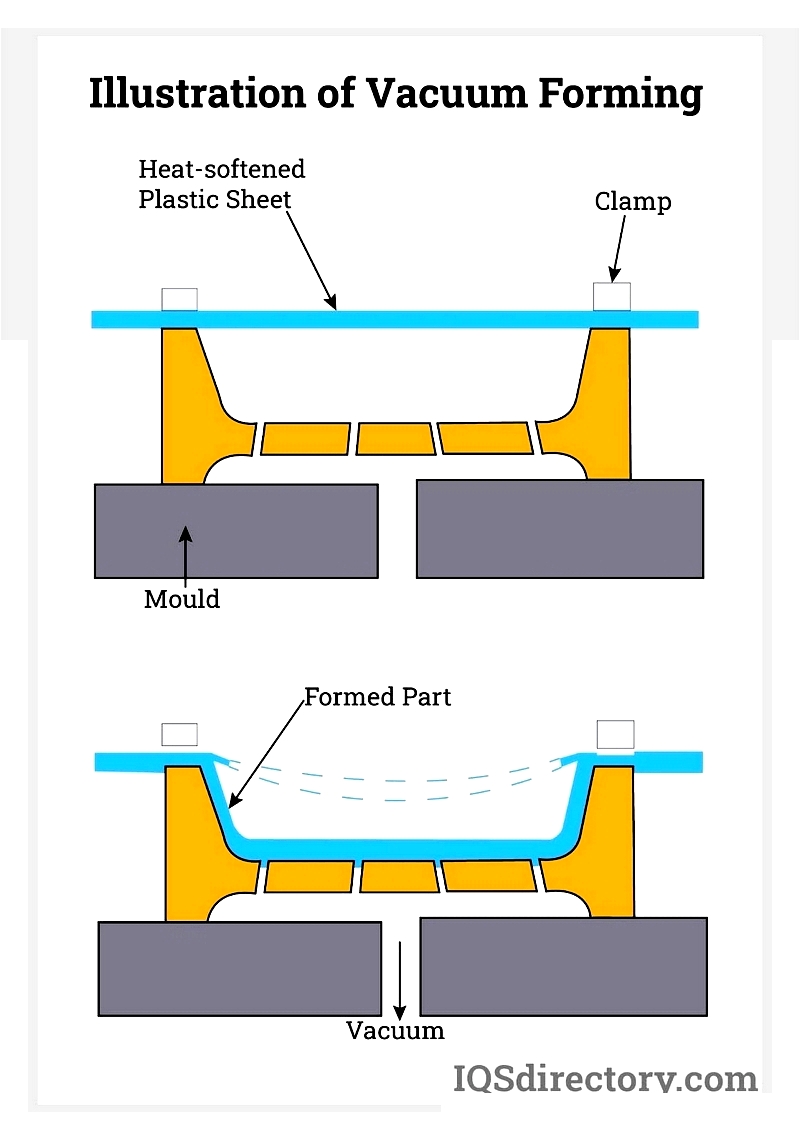

Vacuum forming refers to the process of heating plastic and shaping it using vacuum pressure.

As one of the oldest and most cost-effective plastic molding techniques, vacuum forming is widely used for everyday items and industrial machinery. Its popularity stems from low costs, efficiency, speed, and ease of shaping smaller molds. The process involves placing a plastic sheet over a mold and using suction to form the desired shape. Being the simplest form of plastic thermoforming, it only requires a mold and plastic sheet.

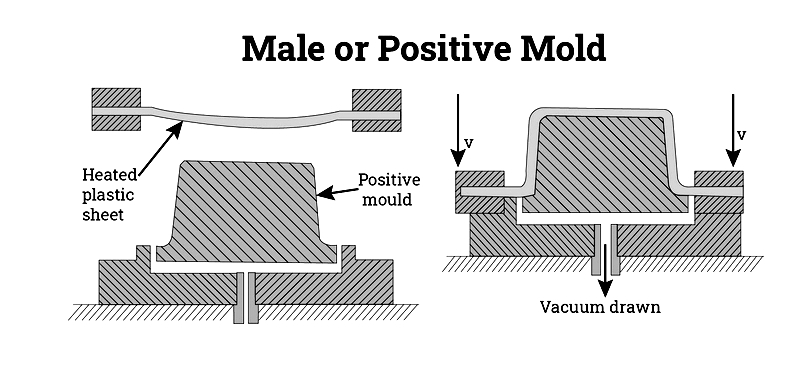

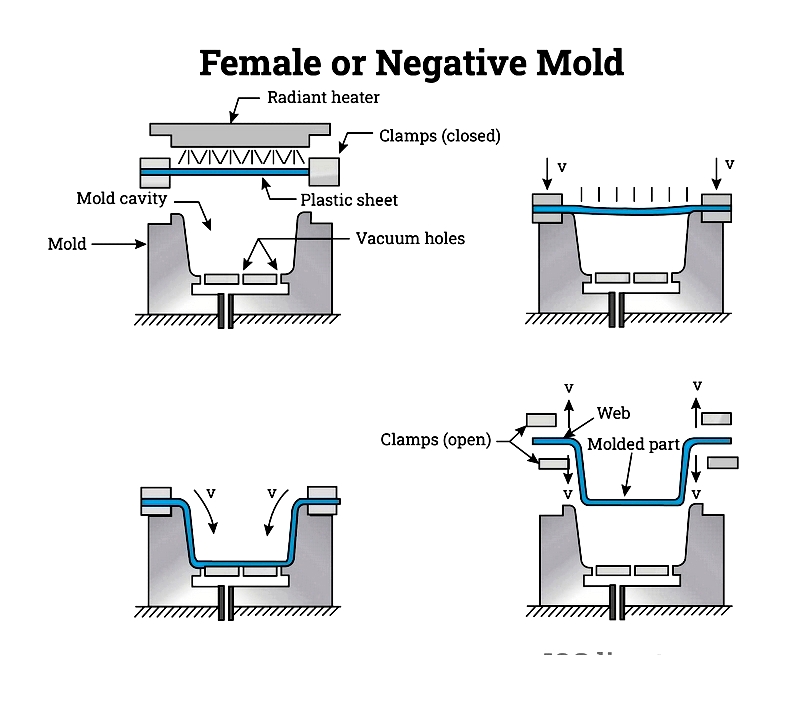

Vacuum forming utilizes two types of molds:

- Male (positive) mold

- Female (negative) mold

The male mold features a convex shape where plastic forms over the outer surface to create inner dimensions. Conversely, the female mold has a concave shape where plastic forms inside to shape outer dimensions accurately.

While vacuum forming is the simplest plastic molding method, modern advancements like heat, hydraulic, and pneumatic controls enable more precise products at faster speeds. This process manufactures various items including bath trays, vehicle parts, refrigerator liners, and storage boxes.

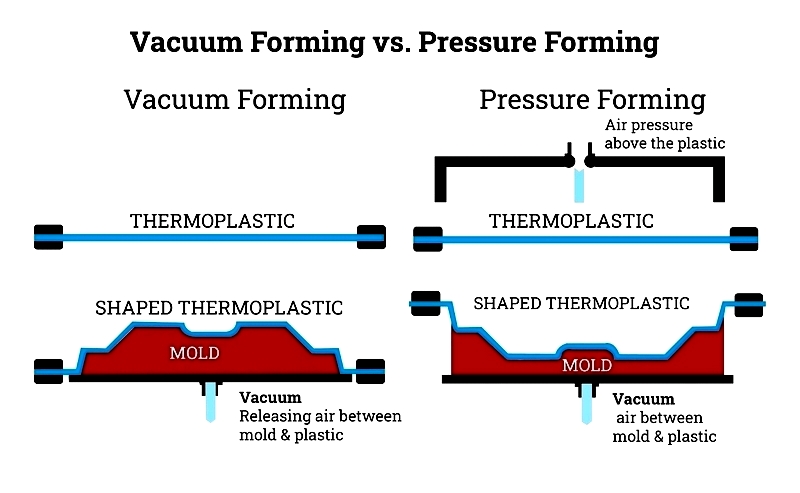

Difference between Thermoforming, Vacuum Forming and Pressure Forming

Thermoforming involves heating plastic sheets to make them flexible, then contouring them into desired molds before trimming the final product. It consists of two main types:

- Vacuum forming

- Pressure forming

The key difference lies in the number of molds used during manufacturing.

Vacuum forming uses a single mold and vacuum pump. A heated plastic sheet is placed over the mold, with vacuum pressure shaping it. This method is common for food packaging and electronics. Pressure forming employs two molds between which the sheet is placed, using pressure rather than suction for shaping. This allows for more precise results like appliance casings and is ideal for deeper molds.

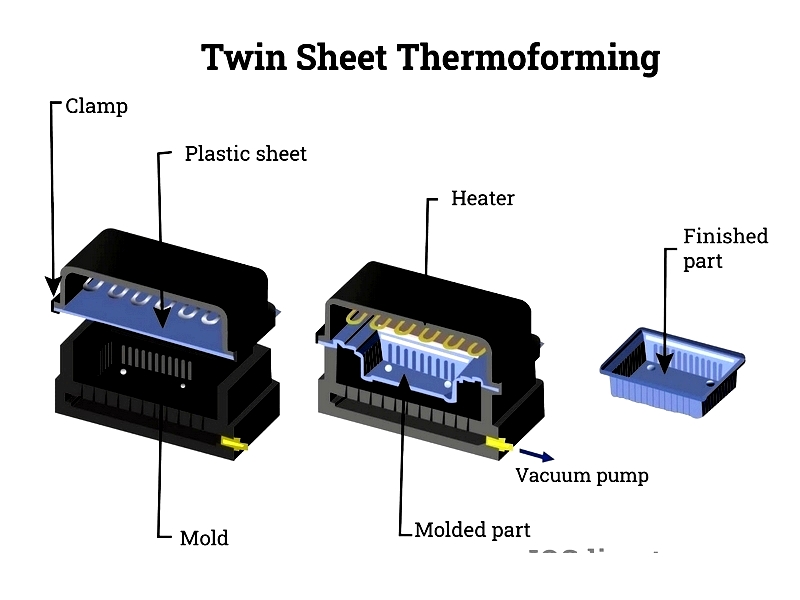

Twin Sheet Thermoforming

Twin sheet thermoforming uses either pressure or vacuum forming with two molds. This compression technique simultaneously forms two plastic sheets - one on the top platen and another on the bottom. The sheets remain under vacuum at melting temperature where platens compress and fuse them into a single product. Commonly used for hollow-structured products, the process is illustrated below:

This method offers several advantages:

- 20-30% lower tooling costs compared to other processes

- Enables enclosed cavity creation

- Produces more rigid and stable products than thin-walled thermoforming

- Allows for internal reinforcements

Applications include pallets, portable toilets, toys, fuel tanks, marine products, doors, ventilation ducts, surfboards, and transportation items.

Materials Used In Vacuum Forming

While various thermoplastics can be used, common materials include:

Polycarbonate (PC)

Polycarbonate is a durable polymer used for machine parts. Nearly unbreakable with high resistance and UV protection, it weighs half as much as glass. Applications include light diffusers, skylights, and aircraft trims.

Polystyrene (PS)

This versatile thermoplastic offers moderate strength, precision, and rigidity. With good electrical properties and low cost, it's commonly used in food packaging and disposable tableware.

Polypropylene (PP)

Used in model making and crafts, PP sheets are semi-rigid with high heat, fatigue, and chemical resistance. They feature crystalline, non-polar, and translucent properties.

Polyvinyl Chloride (PVC)

Widely available and economical, PVC offers excellent tensile strength and rigidity. Eco-friendly and chemical-resistant, it's used in commercial applications like printing and laminations.

Polyethylene (PE)

Derived from petroleum, PE resists water and chemicals while remaining stable in cryogenic conditions. Its low cost and versatility make it widely applicable.

Polyester Copolymer PETG

This thermosetting plastic offers durability, strength, and environmental resistance. Easily molded and shaped, it's ideal for vacuum forming.

Acrylic PMMA

A durable, transparent plastic more economical than glass, used in automotive, smartphone screens, and aquariums.

Acrylonitrile Butadiene Styrene ABS

This water-insoluble thermoplastic resists chemicals, impact, and abrasion. Used for rigid pipes, automotive parts, and wheels.

Chapter 2: Machines Used in Vacuum Forming

All vacuum forming machines operate on the same principle but vary in capabilities. They are categorized into four types:

DIY Machine

Designed for small-scale production with limited heaters, DIY machines are incompatible with industrial use. Simple in structure with three heating zones, they produce items like toys, masks, and tableware.