Introduction

This article provides an in-depth exploration of force calibration.

You will learn about key topics including:

- Characteristics of Force Calibration

- History of Force Calibration

- What is Force Calibration?

- Types of Force Calibration

- Force Calibration Equipment and Gauges

Characteristics of Force Calibration

Force calibration is essential for testing materials used in manufacturing equipment, machines, and devices. As metals and other materials expand and contract during use, understanding their characteristics and durability becomes crucial for both consumer safety and industrial processes. Material properties significantly impact product design by influencing lifespan. evaluating these properties helps determine whether a product can endure the forces it will face.

History of Force Calibration

The need for material testing arose from metal failures in the late 19th and early 20th centuries, which caused catastrophic disasters with severe property damage and casualties. During this period, testing methods lacked proper control and were insufficient to ensure equipment stability.

The Brinell tester was the first testing device, using a 10 mm metal ball pressed against materials via a pneumatic piston. However, its results were unreliable due to inconsistent force from the pneumatic drive.

These inaccuracies led to the development of more precise measuring devices in collaboration with the United States National Bureau of Standards. Over nearly a century, force calibration methods have evolved significantly, with modern instruments providing highly accurate and reliable data.

Force Calibration Measurements

As Sir Isaac Newton observed, motion is governed by force. Effective motion management begins with force management. In physics, force equals mass multiplied by acceleration. Precise force measurement requires specific parameters and benchmarks to ensure instrument accuracy.

The National Institute of Standards and Technology (NIST) provides calibration services for force-measuring instruments. NIST experts apply various forces, including compression and tension, to elastic transducers and record the resulting deformations. Their reports establish correlations between applied force and deformation data.

When companies perform force calibrations, they compare their results with NIST standards. Each device undergoes evaluation for accuracy. Discrepancies prompt adjustments and recalibrations to ensure conformity with established standards.

What is Force Calibration?

Force, whether push or pull, is fundamentally mechanical. Force calibration devices measure the force exerted on objects, materials, or devices. These universal measurements determine tension, compression, and impact limits. Effective calibration requires proper device alignment—plumb, level, square, rigid, and with minimal torsion. Failure to meet these conditions compromises data accuracy.

While force measurement may seem simple, the underlying science and technology for precise readings are complex. Maintaining accuracy and reliability in force calibration is critical for data safety and error minimization.

Manufacturers rely on accurate force measurements to establish product specifications, often including this data in documentation and sales materials. For example, knowing a shipping crane cable's maximum force capacity is essential for safety and defining lifting capabilities.

Cranes are customized based on force calibration results. Inaccurate data can create hazardous conditions, jeopardizing operations and safety. Proper calibration provides vital information to mitigate risks and ensure personnel and equipment safety.

Types of Force Calibration

As a fundamental concept, force requires precise measurement and recording to ensure optimal device and material performance. Over nearly a century, manufacturers have refined calibration techniques to meet specific material requirements with precision.

Tension

Tension calibration measures pulling, stretching, or extending forces, contrasting with compression calibration.

Compression

Compression calibration measures pushing or squeezing forces. Accurate results require proper alignment to ensure direct force application without unintended angles or deviations.

Hardness

Hardness measures a material's resistance to indentation. Smaller indentations under constant force indicate greater hardness, quantified through depth or area measurements using various testing methods.

Impact

Impact testing evaluates material resilience to sudden forces, assessing responses to shock loading like bending, tension, or torsion. This determines material toughness and brittleness susceptibility.

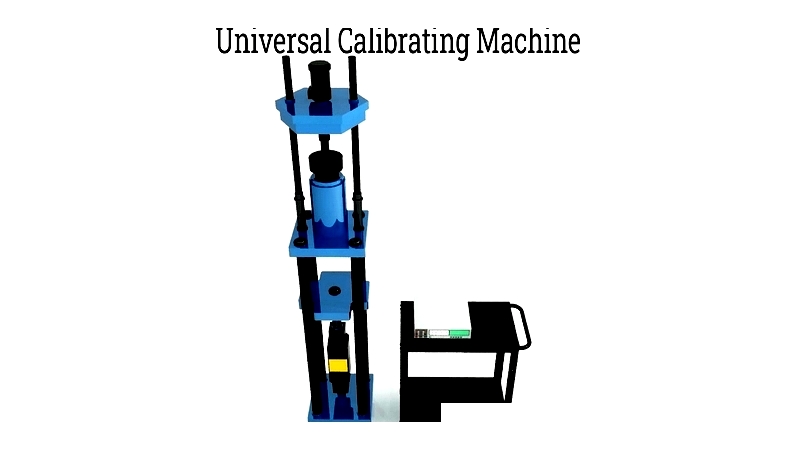

Force Calibration Equipment and Gauges

Force calibration employs diverse instruments, from handheld gauges to large press-like machines, selected based on material and testing standards.

Adapters are essential in all calibration devices, guiding force application for accuracy. Tension calibrations use ball nuts and cups, while compression tests employ ball seats and spherical adapters. Other adapters include pin tension links and alignment plugs.

Load Cell

Load cell calibration compares unknown devices to references, characterizing their performance. These devices convert mechanical energy to electrical signals, requiring regular calibration to maintain accuracy.

Force Gauges

Ideal for push/pull tests on springs, metal wires, and gun triggers.

Test Stands

Available in manual and motorized versions for material and product evaluation.

Tension Dynamometers

Measure output force.

Wheel Pads

Designed for vehicle weighing.