Introduction

This article provides an in-depth exploration of cold heading and cold forming processes.

Key topics covered include:

- Principles of Cold Heading

- Various Cold Heading and Cold Forming Processes

- Applications and Benefits of Cold Forming

- Additional relevant information

Chapter 1: Understanding the Basics of Cold Forming

This chapter examines the fundamentals of cold forming, including material selection and tooling methods used in production.

Understanding Cold Heading

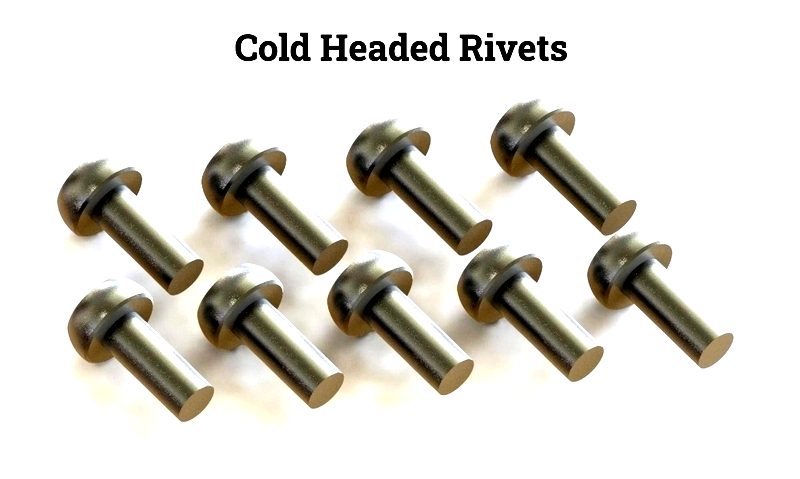

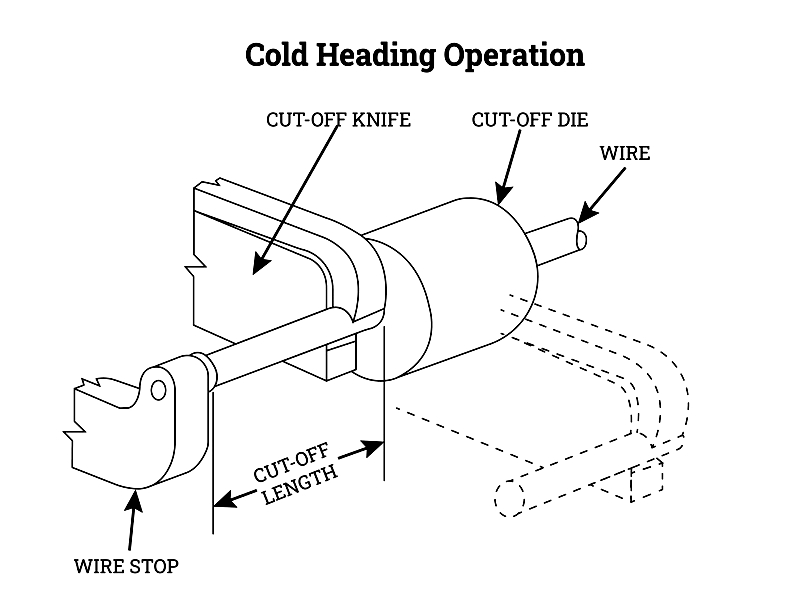

Cold heading, or cold forming, shapes metal wire at room temperature using high-speed hammers, dies, and punches.

The process starts by cutting wire slugs, which are then formed through successive hammering and die operations that exceed the metal's yield strength.

This forging technique produces threaded fittings and fasteners through operations like rolling, piercing, and trimming without heat application.

Originally for simple fasteners, modern cold heading now handles complex components in tough alloys through automated, multi-station processes.

Tools and Materials in Cold Forming

Specialized equipment cuts and measures wire coils, with variations among manufacturers' feeding mechanisms.

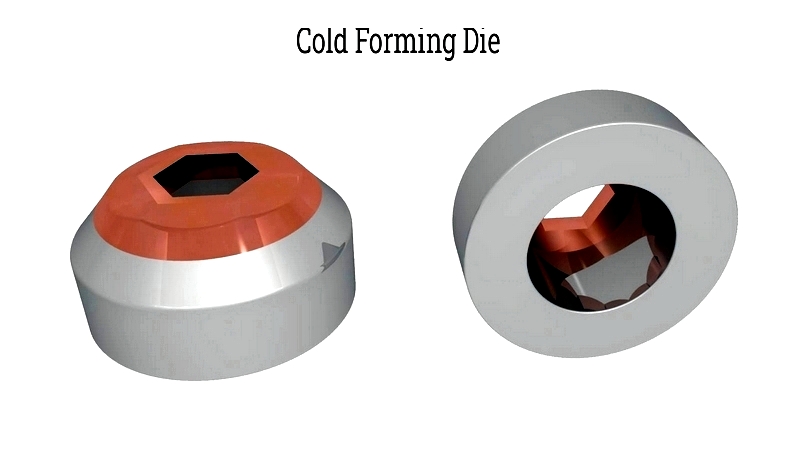

Cold Forming Dies

Stationary dies withstand high pressures through segmented construction within reinforced casings.

Proper die support prevents premature failure, with knock-out pins ensuring part release after forming.

Cold Forming Punches

Movable punches shape screw heads through multiple impacts while supporting extrusion operations.

Cold Forming Transfer

Precision transfer systems move parts between dies in multi-station headers, requiring exact timing.

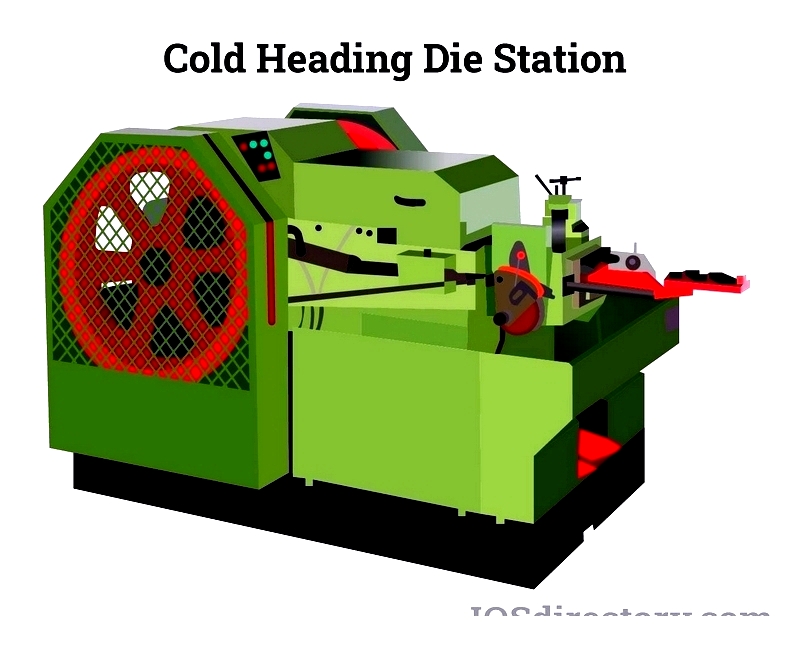

Cold Heading Machines and Processes

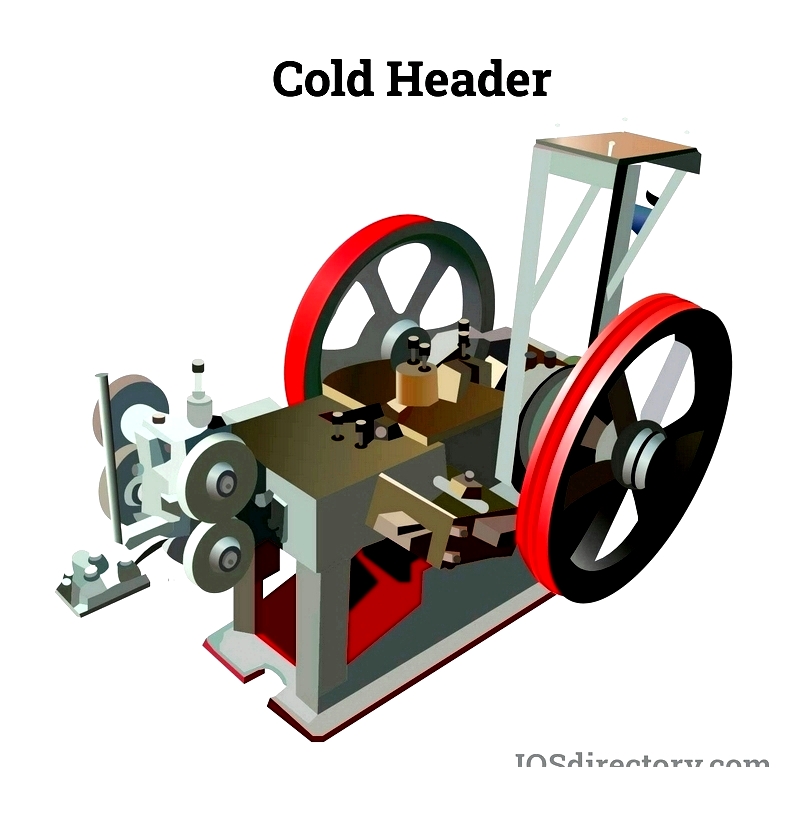

Reciprocating rams drive hammers into dies to transform metal blanks into precise shapes.

Modern machines feature improved gear systems for quieter operation and higher productivity.

The Art of Cold Heading

Automated equipment converts wire into complex components at rates up to 400 parts per minute with minimal waste.

Innovations in Cold Forming Machinery

Recent advancements include multi-die configurations and CNC controls for efficient production of diverse parts.

Improved metallurgy enables forming stronger materials while extending tool life through specialized alloys.

Chapter 2: Types of Cold Heading Processes

Types of Cold Heading Equipment

Cold heading systems fall into two main categories:

- Part formers

- Cold headers

Both use horizontal rams to shape metal at room temperature, ranging from single-die to seven-die configurations.

Types of Cold Heading Processes

Cold heading primarily involves upsetting and extrusion techniques for metal forming.

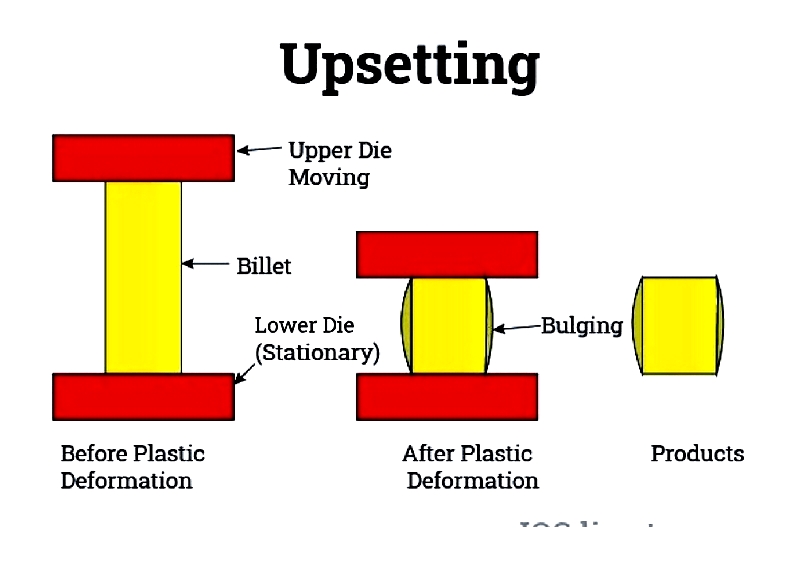

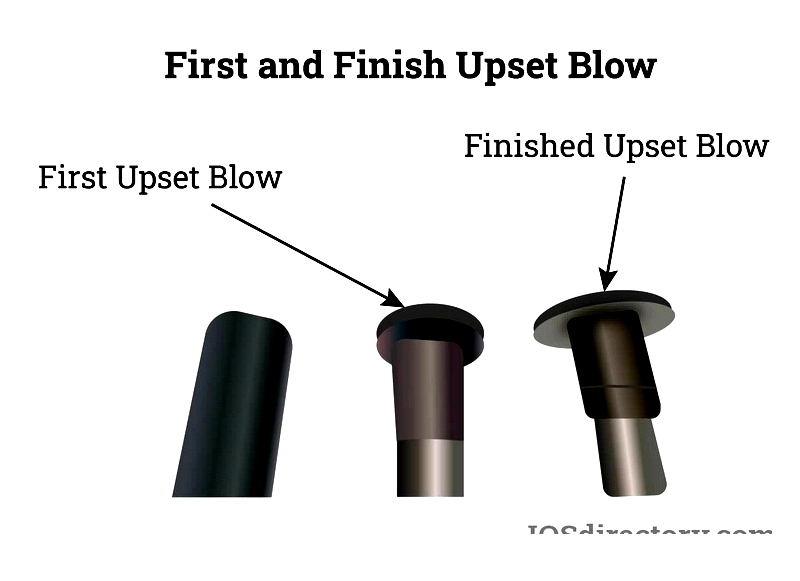

Cold Heading Upsetting

This process forms fastener heads by consolidating material through controlled deformation.

Multiple die stations enable complex head geometries while maintaining material integrity.

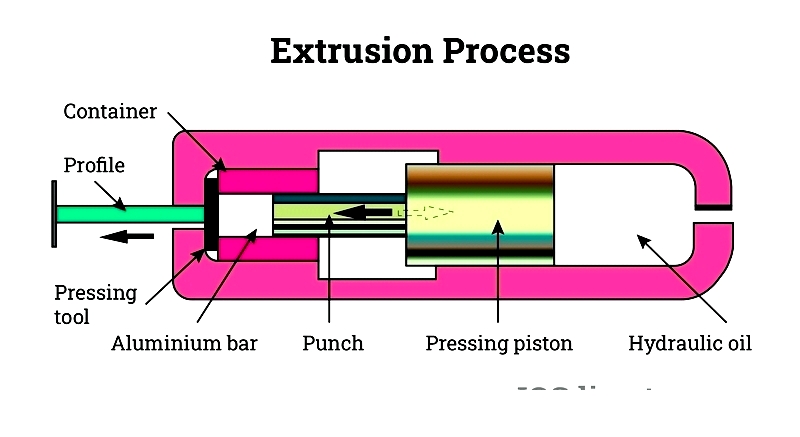

Cold Heading Extrusion

Extrusion techniques include:

- Forward extrusion (trapped and open)

- Reverse extrusion

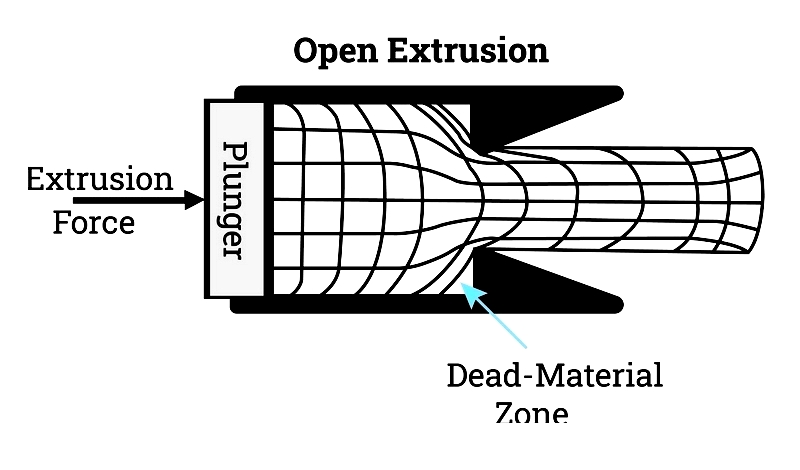

Open Extrusion

Produces long, slender components with greater material flow but higher force requirements.

Trapped Extrusion

Enables complex geometries through fully contained forming with greater diameter reduction.

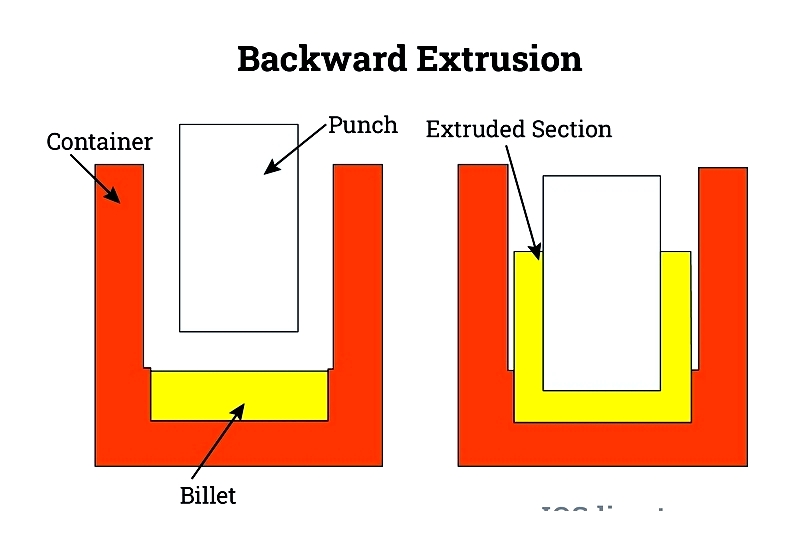

Reverse Extrusion

Creates hollow features like internal recesses and drive sockets in fasteners.

Chapter 3: Applications and Advantages of Cold Heading

This chapter examines cold heading's industrial uses and benefits.

Applications of Cold Heading

The process efficiently produces high-quality fasteners from specialized cold heading steels and alloys.

Advantages of Cold Forming

Key benefits include:

Fast Production

High-speed operations yield up to 100 parts per minute with consistent quality.

Added Strength

Maintains material grain structure for enhanced durability.

Reduced Energy Consumption

Eliminates heating requirements found in hot forging processes.

Drawbacks of Cold Heading

Limitations include:

Size Limitations

Practical constraints exist for extremely large fastener production.

Material Limitation

Not all metals are equally suitable for cold forming processes.

Conclusion

Cold heading has significantly advanced manufacturing technology, offering efficient production of high-quality components when properly applied.