Introduction

This article provides an in-depth examination of Polyvinyl Chloride (PVC).

It covers various topics including:

- The composition and manufacturing process of PVC

- Different types, properties, and additives used in PVC

- Benefits, applications, and recycling methods for PVC

- Additional relevant information

Chapter 1: PVC Production Process

This section explores the manufacturing procedure of Polyvinyl Chloride (PVC).

Polyvinyl Chloride Overview

PVC, a durable white thermoplastic, combines lightweight properties with remarkable resilience. First synthesized in 1872 by German chemist Eugen Baumann through sunlight exposure of vinyl chloride gas, PVC became widely used from 1913 onward, particularly for corrosion-resistant piping. Available in flexible, unplasticized, and modified forms, PVC offers excellent dielectric strength, flame retardancy, and chemical resistance. To enhance its thermal stability and melt viscosity, manufacturers incorporate various additives during production.

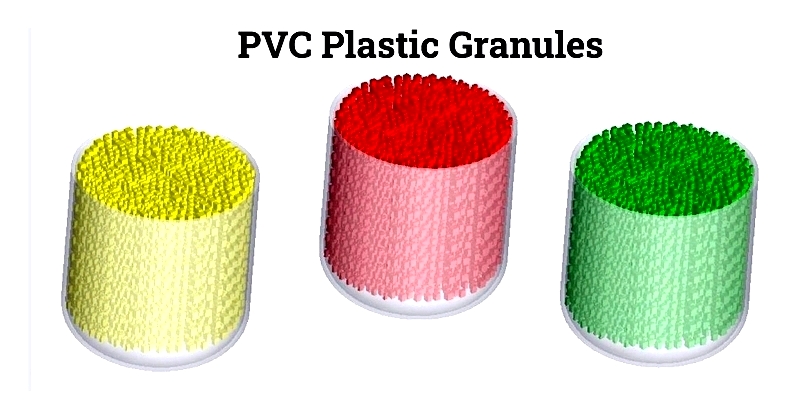

The polymerization of vinyl chloride produces PVC, with its properties varying according to the plasticizers used. These low molecular weight substances improve flexibility and are carefully selected for chemical compatibility with PVC polymers.

PVC Manufacturing Process

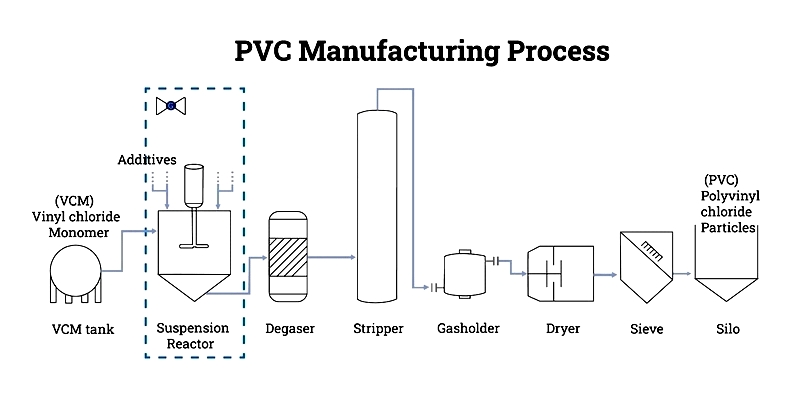

This section details the production methodology for PVC.

Raw Material Sources

PVC production utilizes two primary raw materials, reducing reliance on non-renewable resources. Approximately 57% originates from common salt, while the remaining 43% comes from hydrocarbon feedstocks. Recent developments include using bio-sourced ethylene as an alternative to petroleum-based materials.

The manufacturing process involves five key stages: resource extraction, chlorine and ethylene production, VCM formation, polymerization, and final formulation. Ethylene undergoes cracking processes before combining with chlorine to create EDC, which subsequently produces VCM through thermal cracking.

PVC Production Techniques

This section outlines various polymerization methods used in PVC production.

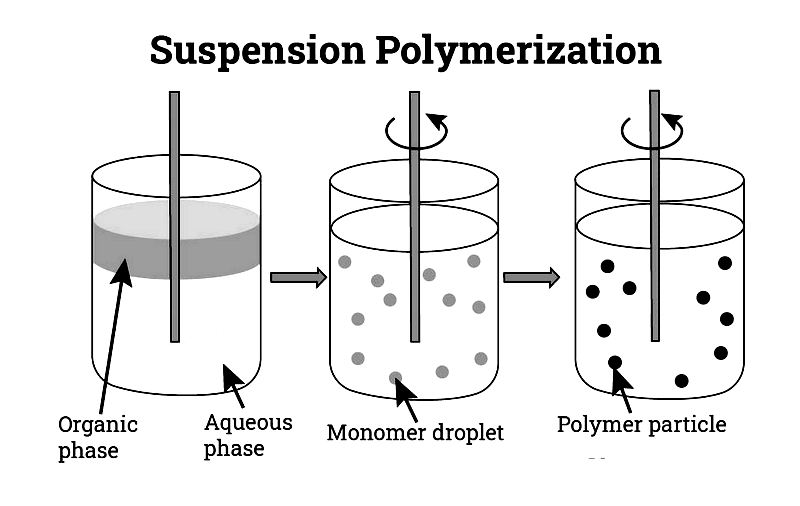

Suspension Polymerization

This method suspends monomer droplets in water, transforming them into spherical polymers through controlled agitation. The process maintains consistent viscosity and produces particles with specific size distributions crucial for plasticizer absorption.

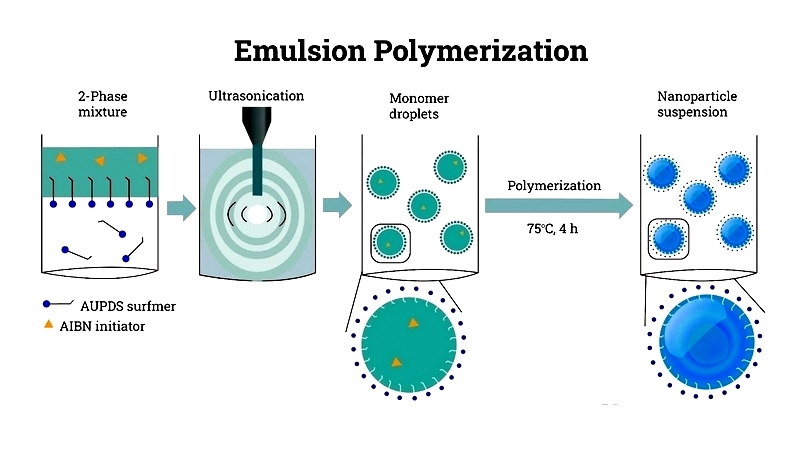

Emulsion Polymerization

This continuous feed process achieves high conversion rates and precise particle composition control. It enables the creation of multimodal particle distributions through careful surfactant management and reactor design.

Bulk Polymerization

The simplest production method uses only initiator and monomer, though it presents challenges in heat management and viscosity control. Suitable for various polymer types, it requires efficient cooling systems to handle exothermic reactions.

Chapter 2: PVC Tubing Production Equipment

North American manufacturers employ advanced machinery for efficient PVC tubing production, serving industries from construction to automotive. The following sections detail leading extrusion technologies.

Battenfeld-Cincinnati Conical Twin Screw Extruder

Manufacturer: Battenfeld-Cincinnati

This energy-efficient system processes both rigid and flexible PVC compounds, delivering high throughput with precise dimensional control. Its advanced temperature regulation ensures consistent product quality across various tube diameters.

KraussMaffei Single Screw Extruder

Manufacturer: KraussMaffei

Renowned for versatility, this extruder handles diverse PVC blends and integrates seamlessly with downstream equipment. Its variable speed controls support custom profile production while maintaining energy efficiency.

Davis-Standard Downstream Equipment

Manufacturer: Davis-Standard

This comprehensive system features vacuum sizing tanks and automated cutting units that enhance production efficiency. When paired with quality extruders, it ensures compliance with industry standards for tube geometry.

Bausano Twin Screw Extruders

Manufacturer: Bausano & Figli S.p.A.

Notable for digital process controls, these extruders accommodate specialized PVC formulations. Features include real-time monitoring and rapid color change capabilities for flexible production cycles.

American Kuhne Extrusion Equipment

Manufacturer: American Kuhne

These modular systems support everything from pilot lines to full-scale production. Their ergonomic design and advanced controls make them ideal for medical-grade and custom PVC tubing applications.

Chapter 3: PVC Varieties

This section examines different PVC types, their characteristics, and specialized applications.

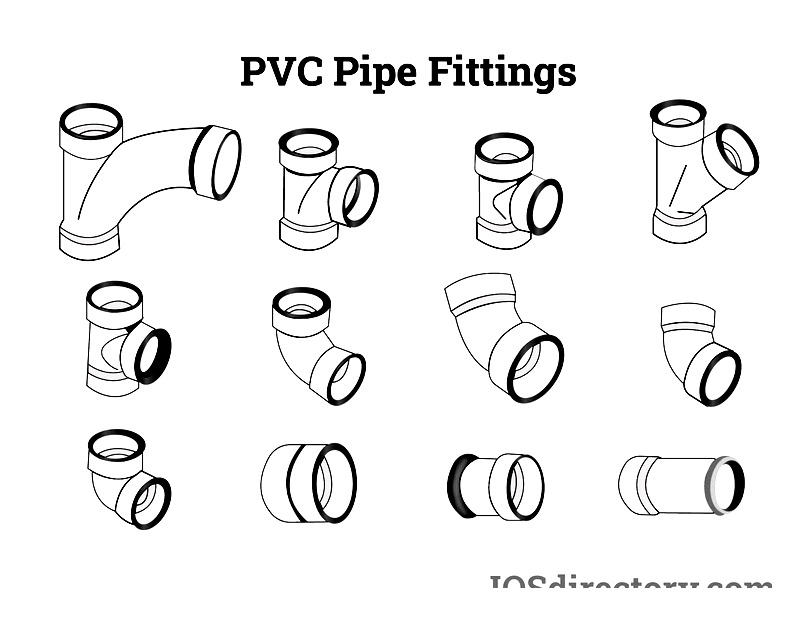

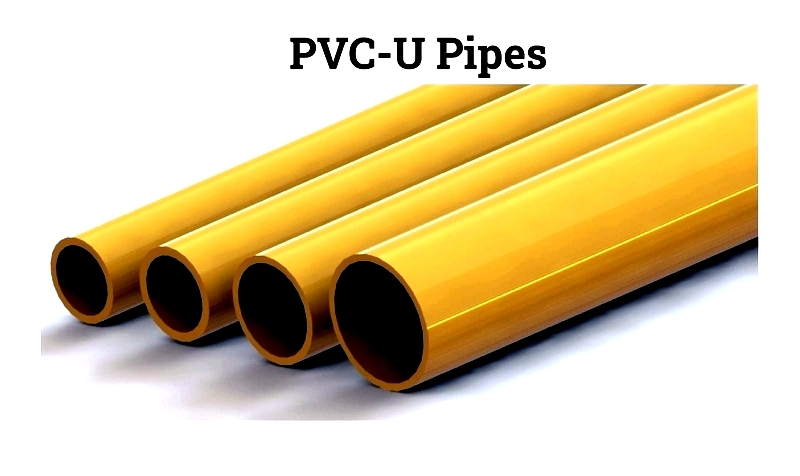

PVC-U Pipes

Unplasticized PVC offers rigidity and chemical resistance, making it ideal for water distribution and drainage systems. Its recyclability supports sustainable construction practices.

PVC-O Pipes

Molecular orientation enhances these pipes' durability and pressure resistance. Their superior hydraulic capacity suits large-scale irrigation and water transmission applications.

C-PVC Pipes

Chlorination improves temperature resistance, making these pipes suitable for hot water systems and industrial plumbing. They maintain PVC's cost-effectiveness while expanding application possibilities.

PVC-Hi Pipes

Enhanced with impact modifiers, these pipes withstand demanding conditions in gas and fluid transport. They meet stringent safety standards for industrial infrastructure projects.

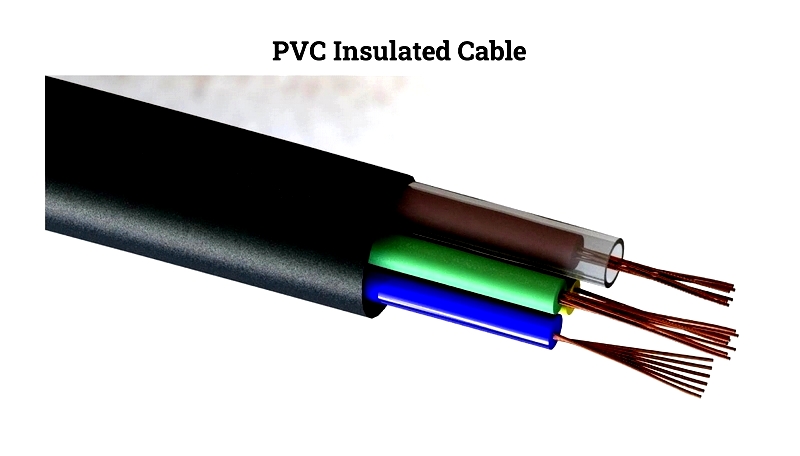

PVC Cables

PVC-insulated wiring offers durability and fire resistance for electrical applications. Advances include low-smoke, halogen-free options for enhanced safety in building environments.

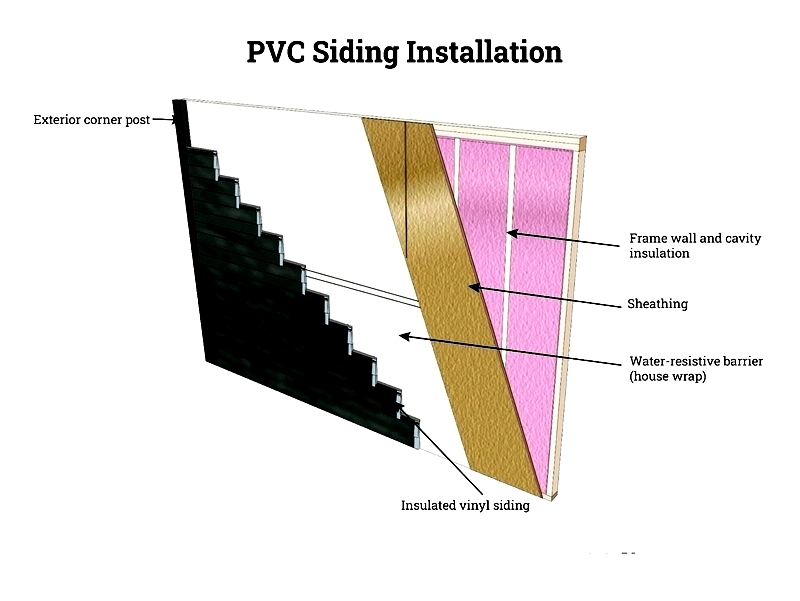

PVC Siding

This exterior cladding solution provides weather resistance and energy efficiency for buildings. Its maintenance-free properties and design flexibility make it a popular construction material.

PVC Packaging

Versatile PVC packaging ensures product safety in food and pharmaceutical applications. Its barrier properties extend