Introduction

This article provides an in-depth exploration of hot melt adhesives.

It covers various aspects including:

- Principles of Hot Melt Adhesives

- Manufacturing Processes and Properties

- Different Types of Hot Melt Adhesives

- Applications, Benefits, and Advantages

- Performance Characteristics, Cost Factors, and Functional Aspects

- And more...

Chapter 1: Understanding Hot Melt Adhesive Principles

This chapter explores the fundamentals of hot melt adhesives, detailing their production methods and operational mechanisms.

What Are Hot Melt Adhesives?

Hot melt adhesives, often referred to as hot glue, are thermoplastic polymers that remain solid at room temperature but liquefy when heated above their softening point.

Compared to other packaging materials, these adhesives have relatively low softening temperatures, making them suitable for diverse industrial applications. When heated, they become liquid and active, enabling effective surface bonding.

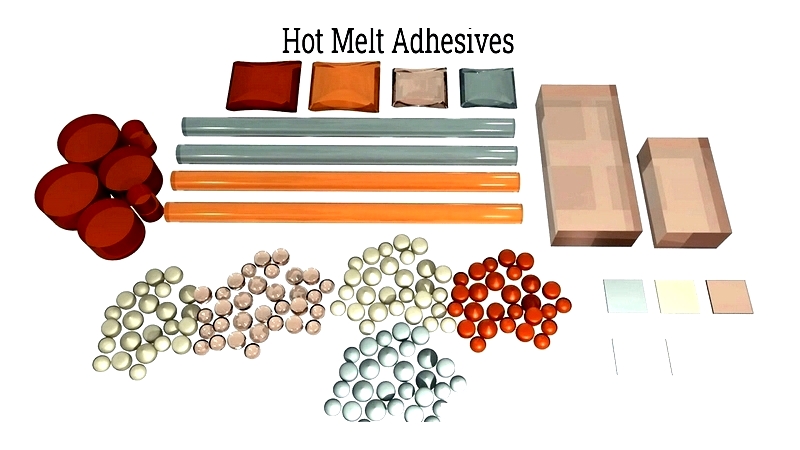

In solid form, they are available as beads, blocks, pellets, chips, pillows, or glue sticks. Application methods vary from nozzle extrusion to spraying or rolling, depending on the intended use.

Essential Components of Hot Melt Adhesives

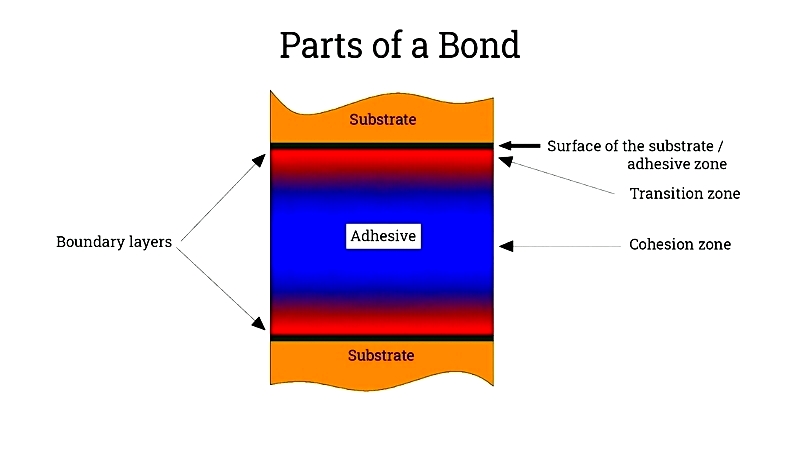

The composition of hot melt adhesives directly impacts their cost, performance, functionality, and availability. Typically, they consist of a polymer base combined with various additives, each serving specific purposes.

Common additives include antioxidants, resins, plasticizers, and waxes, with additional chemicals incorporated to enhance particular adhesive properties.

Polymers in Hot Melt Adhesives

Polymers form the backbone of hot melt adhesives. These long molecular chains determine key physical characteristics such as heat resistance, flexibility, and bond strength.

Polymer type, molecular weight, and concentration influence properties like shear and impact resistance. Higher polymer content increases viscosity (liquid thickness) while improving toughness and flexibility.

Resins in Hot Melt Adhesives

Resins significantly affect tack (stickiness) and wetting properties, which govern adhesive behavior in liquid state on surfaces.

Resin selection depends on factors like softening point and polymer compatibility. Common types include rosin derivatives and hydrogenated hydrocarbons.

Higher resin content reduces tack and drying time, while lower content produces more aggressive, durable bonds.

Waxes in Hot Melt Adhesives

Waxes primarily control open time (bonding duration) and set speed (bond formation rate), which must align with production requirements.

They also influence heat resistance and low-temperature adhesion. Varieties include synthetic, microcrystalline, and natural waxes with differing molecular weights and melting points.

Reduced wax content increases viscosity and flexibility, while higher wax content decreases viscosity and accelerates setting.

Antioxidants in Hot Melt Adhesives

Antioxidants prevent adhesive degradation over time. Common types are aromatic amines, phenols, and phosphites, often combined with stabilizers to protect the molten adhesive without altering physical properties.

Plasticizers in Hot Melt Adhesives

These additives enhance toughness and flexibility while reducing melt viscosity for better wetting. Typically hydrocarbon-based, they contain minimal aromatic content.

Additional specialty additives may include biocides, fillers, pigments, flame retardants, or decorative elements like glitter for specific applications.

Chapter 2: Manufacturing Processes and Properties of Hot Melt Adhesives

This chapter examines production methods and characteristic properties, explaining why these adhesives are widely used in manufacturing and packaging.

Manufacturing Process

Hot melt adhesives are thermoplastic bonding agents that soften when heated and harden upon cooling, creating instant, durable bonds. Being solvent-free, they cure quickly without substrate warping. Key ingredients include resins, polymers (EVA copolymers, polyolefins, polyamides), plasticizers, waxes, tackifiers, and antioxidants - each contributing to adhesion, flexibility, and processing characteristics.

During manufacturing, raw materials are precisely weighed, blended in heated vessels, and formed into homogeneous molten mixtures. Formula selection depends on application: packaging, woodworking, automotive, etc. Common types include PUR, metallocene polymers, EVA, and polyethylene hot melts, chosen for their bonding strength and substrate compatibility.

The molten adhesive is cooled into pellets, chips, blocks, or sticks for easy handling. Industrial users often melt bulk forms in melter systems integrated with automated dispensers.

Applied as liquid via spraying, rolling, extrusion, or other methods, the adhesive has a brief open time for surface wetting before bonding under pressure. Rapid cooling creates durable bonds ideal for high-speed production.

Key Properties

Hot melts offer unique performance characteristics that make them preferred for industrial bonding. Compared to solvent-based alternatives, they provide faster handling, lower VOC emissions, and greater versatility.

Viscosity: Measures flow resistance, crucial for application precision. Affected by temperature (typically 250-350°F/121-176°C) and shear rate, it's measured in poise using specialized instruments.

Color: evaluated using standardized scales (Hunter, Gardner, etc.) for applications where appearance matters, like bookbinding or premium packaging.

Peel Strength: Measures bond separation force (lbs/inch), important for flexible substrates undergoing movement.

Failure Temperature: The temperature at which adhesive performance degrades, tested under peel or shear conditions.

Softening Point: Temperature where flow begins, determined by ring-and-ball or Mettler methods. Higher values suit high-temperature applications.

Substrate Adhesion: Varies by material, tested under different temperatures for multi-substrate compatibility.

Thermal Stability: Indicates resistance to degradation at high temperatures, minimizing production downtime.

Cold Crack Resistance: Measures low-temperature performance, crucial for freezer packaging (-12 to 7°C range).

Loop Tack: evaluates pressure-sensitive adhesives (labels, tapes) by measuring removal force (ounces).

Mechanical Properties: Include yield point (permanent deformation threshold) and tensile strength, important for structural applications.