Introduction:

This article provides a comprehensive overview of stainless steel perforated sheets.

By the end, readers should understand:

- What perforated steel sheets are, their characteristics, properties, and selection criteria

- The manufacturing process of stainless steel perforated sheets

- Different types of stainless steel perforated sheets

- Final products made from stainless steel perforated sheets

- Industries that utilize stainless steel perforated sheets

- Applications and benefits of stainless steel perforated sheets

- And more...

Chapter One: Understanding Perforated Steel Sheets: Characteristics, Properties, and Selection Criteria

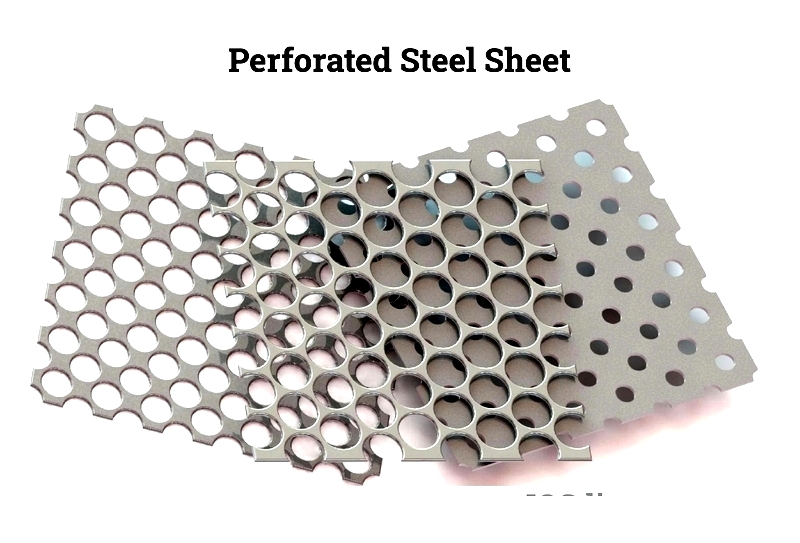

Manufacturers create perforated stainless steel sheets by cutting, punching, or stamping specific hole patterns. These sheets serve both functional purposes like filtration and ventilation, as well as aesthetic applications in architectural design.

Beyond their visual appeal, perforated steel sheets offer practical benefits. They transmit light while providing effective screening solutions. Additionally, they help reduce noise levels, creating quieter environments. Architects frequently use these sheets as decorative elements, while industries like acoustics, food processing, chemicals, and energy rely on them for efficient fluid filtration.

Key Selection Factors for Perforated Steel Sheets

Application

The primary consideration when selecting perforated steel sheets is their intended use. Understanding the product's specific requirements significantly influences other selection factors.

Material

Perforated sheets come in various base materials, each suited for different applications. Common options include:

- Steel varieties: cold-rolled, hot-rolled, galvanized, aluminized, and pre-painted

- Stainless steel options: protective film-coated, 400-series, T304, and T316

Hole Sizes

Perforated steel sheets feature various hole sizes and configurations. Pricing depends on material thickness, hardness, hole dimensions, spacing, and production costs.

Customized Sheets

Stainless steel perforated sheets are available in multiple dimensions:

- Thickness: 0.45mm to 3mm

- Length: 1829mm to 2438mm

Manufacturing Process

Manufacturers produce perforated stainless steel from 15 different grades, offering resistance to bacteria, rust, and corrosion. These sheets come in various finishes and can feature round, square, oval, or custom-shaped holes for intricate designs.

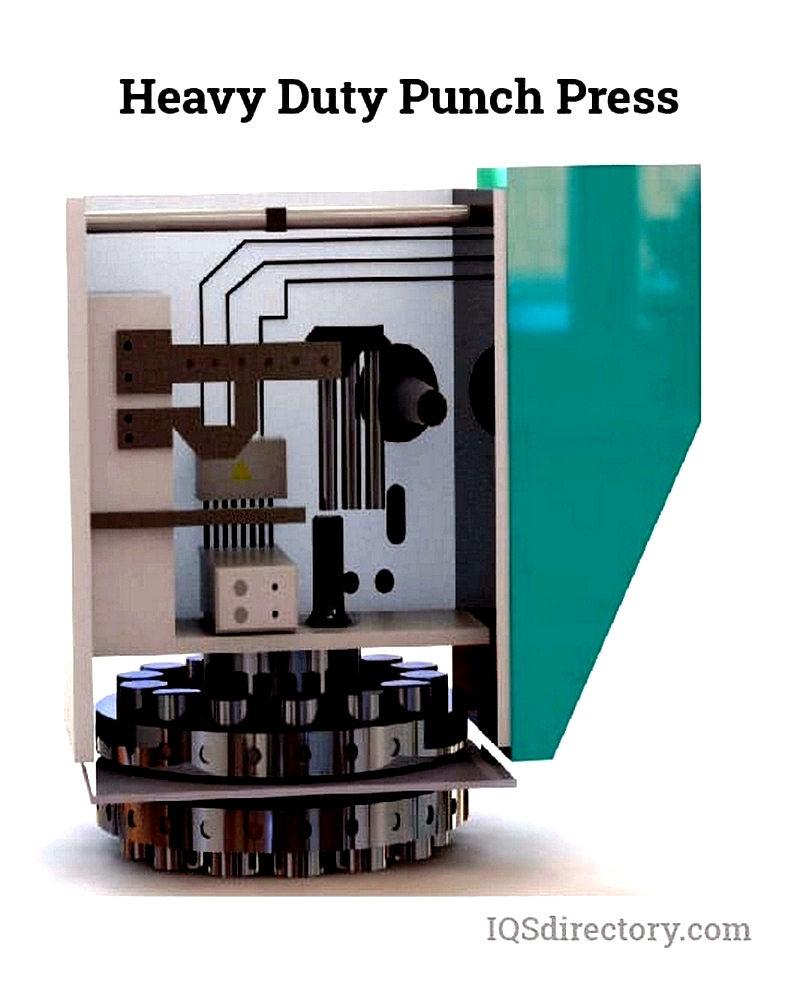

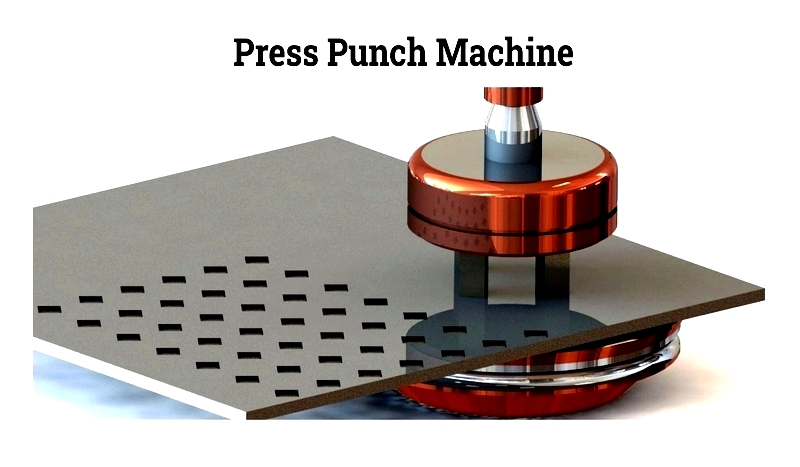

Two primary perforation methods exist, both beginning with feeding steel sheets into a punching press:

- All-cross-perforated presses create simple, repetitive patterns across entire sheets

- Sectional two-axis presses form unique, complex designs

CNC machines typically complete non-repetitive hole patterns by sliding sheets beneath fixed punching rams.

Chapter Two: Manufacturing Stainless Steel Perforated Sheets

Material Selection

The process begins with selecting high-quality, thin stainless steel sheets, typically grades 304 or 316, known for their durability and corrosion resistance. Sheet thickness, measured in gauges, affects manufacturability and performance in various industries.

Pattern Determination

The intended application dictates the hole pattern, with options ranging from standard to custom designs. Round holes maximize airflow, while custom patterns enhance aesthetics or filtration efficiency.

Hole and Bar Sizing

The balance between hole size and bar width impacts sheet strength. Generally, sheet thickness shouldn't exceed hole diameter or bar width to maintain structural integrity during processing.

Production Methods

Perforating Press

All-across perforating presses deliver up to 1600 punches per stroke, efficiently producing sheets for large-scale projects. This method handles materials from 0.002 to 0.25 inches thick at high speeds.

XY Axis Punch Press

This method creates symmetrical holes in sections, allowing for intricate, non-repetitive patterns ideal for custom jobs requiring precise hole arrangements.

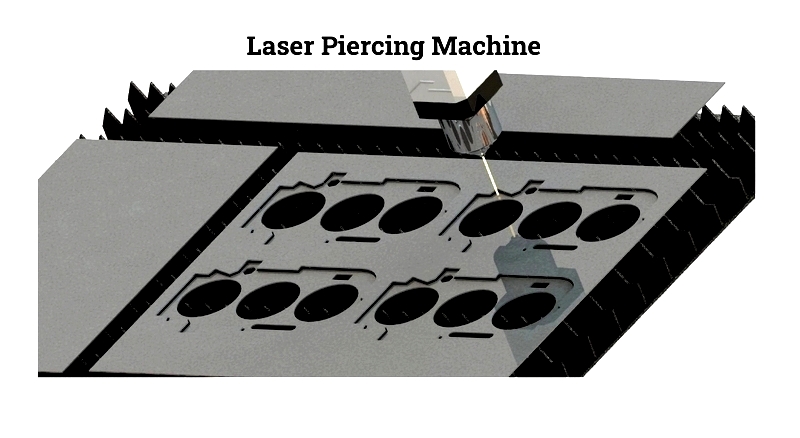

Laser Piercing

Laser perforation offers the highest precision for complex geometries, using CO2 or fiber lasers to create reinforced holes for demanding applications.

Plasma Cutting

This method uses electric arcs and gas to cut through thick stainless steel sheets at speeds up to 20 meters per minute, suitable for heavy-duty industrial applications.

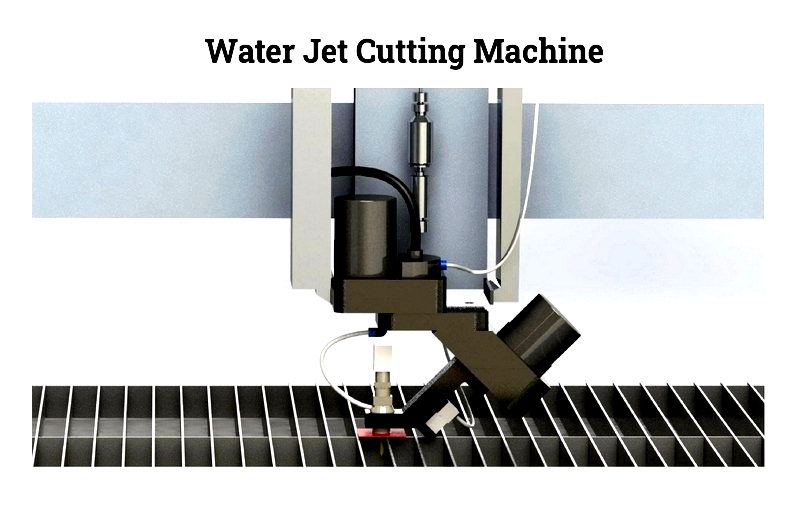

Waterjet Cutting

High-pressure water, sometimes with abrasives, cuts detailed designs without heat distortion, making it ideal for heat-sensitive materials and precision components.

Nibbling

This process uses repeated punching to create complex shapes, particularly useful for prototypes or custom fabrication requiring non-standard hole patterns.

Leveling

After perforation, sheets undergo leveling to remove curling, ensuring flatness for consistent fabrication and installation. Both automated and manual methods achieve this.

Value-Added Processes

Additional treatments like welding, bending, and powder coating enhance functionality and appearance. Powder coating, for instance, adds durable, decorative finishes in various colors.

Selection Guide

Choose perforated sheets based on material grade, hole pattern, thickness, and finish requirements. For corrosion-resistant applications, 316 stainless steel is recommended, while 304 offers cost-effective solutions for general use. Consult suppliers for optimal sheet dimensions and custom services.

Chapter Three: Leading Stainless Steel Perforating Machines

High-quality perforating machines serve industries from architecture to automotive manufacturing. Top manufacturers in North America offer advanced equipment for precise, efficient production of perforated components.

Trumpf TruPunch 3000 Series

Manufacturer: Trumpf

This CNC turret punching machine features automatic tool changing and intelligent programming for high-speed, precise perforation with minimal waste.

Amada AE-2510NT Series

Manufacturer: Amada

Known for energy efficiency and fast cycles, this hydraulic punching machine handles complex designs and integrates easily with modern manufacturing systems.

Finn-Power C5 Series

Manufacturer: Prima Power

This reliable machine combines high-torque hydraulics with automation for maximum throughput in commercial and industrial applications.

Murata Motorum 2048EZ

Manufacturer: Murata Machinery

A servo-driven punch press offering energy-efficient operation and precision tooling for custom metalwork and architectural applications.

LVD Strippit PX-Series

Manufacturer: LVD Company

This rugged machine delivers consistent perforations across various thicknesses