Introduction

This article provides information about tool cases and their uses.

You will learn about:

- What a Tool Case is

- Different Types of Tool Cases

- Materials Used in Tool Case Construction

- The Manufacturing Process of Tool Cases

- And much more...

Chapter One: What is a Tool Case?

A tool case is a portable storage unit designed to keep tools organized, secure, and easily accessible. Basic tool cases work well for general purposes, while specialized and custom options cater to specific needs. For example, custom foam padding that conforms to tool shapes offers extra protection for delicate instruments and electronic devices.

Tool cases typically feature a durable outer shell that creates a tight seal against water, dirt, corrosive liquids, and environmental contaminants. Available in various sizes, they range from compact portable models to larger wheeled versions for easy transportation. Each case is designed to meet users' specific requirements.

For professionals like field technicians, plumbers, and truck drivers, tool cases are essential. They provide a practical way to organize and quickly access the tools and equipment needed for their work.

Chapter Two: What are the Different Types of Tool Cases?

Modern tool cases are designed to meet specific user needs, unlike traditional toolboxes. Manufacturers produce cases for various professions and situations, from IT repairs to offshore oil rig maintenance. These diverse applications require high-quality, durable materials that can withstand challenging work environments.

The days of simple metal boxes for tool storage are gone. Today's tool cases feature durable plastic construction with compartments for better organization and quick access. Just as technology has advanced in other areas, it has also transformed the traditional toolbox.

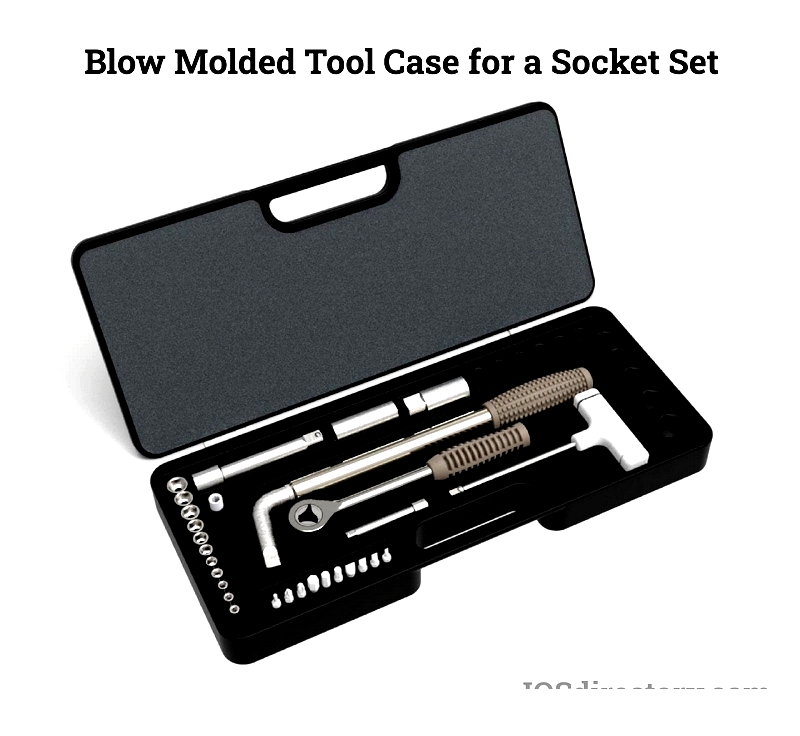

Blow Molded

Blow-molded tool cases are increasingly popular for securely holding power tools. Many are designed to store single tools or sets for specific applications.

Known for their robust construction, blow-molded cases provide excellent protection, especially for technical equipment. The molded design keeps tools securely in place, reducing damage risk during transport. These cases work well for organizing multi-component sets like sockets, screwdrivers, and diagnostic tools.

Briefcase

Tool briefcases resemble standard business cases but are designed for technicians who need to maintain a professional appearance. They're typically wider than regular briefcases and made from durable materials for rugged use.

Like standard briefcases, they come in various designs with multiple compartments, tool organizers, and sections for documents and manuals.

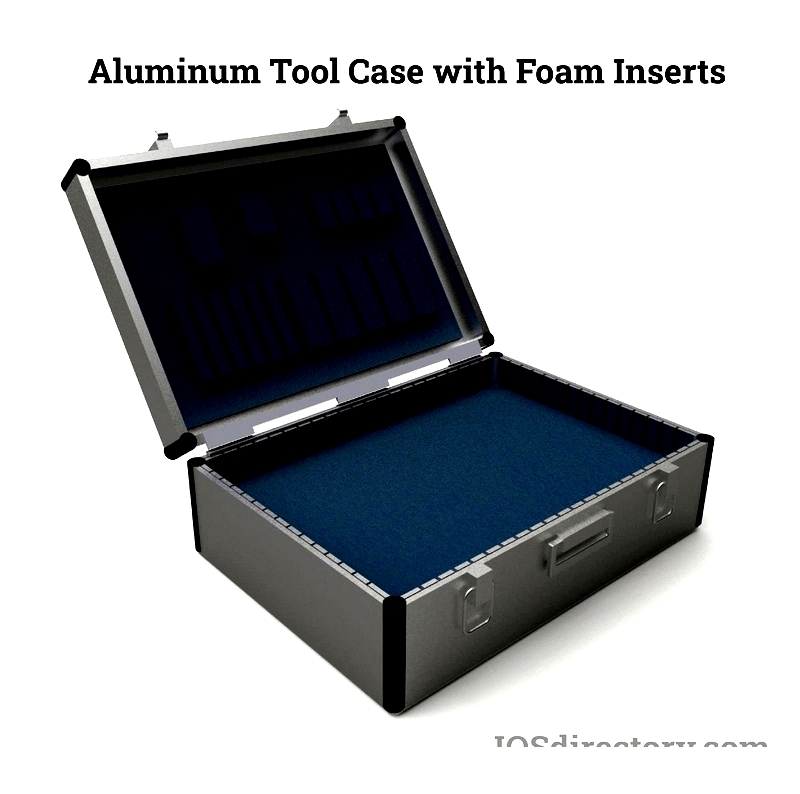

Foam Insert

Foam insert cases protect delicate tools that require stability for accuracy. Particularly favored by technicians needing precise measurements, these cases can be custom-fitted to each tool's exact shape.

Some feature colored foam inserts for better tool visibility and organization.

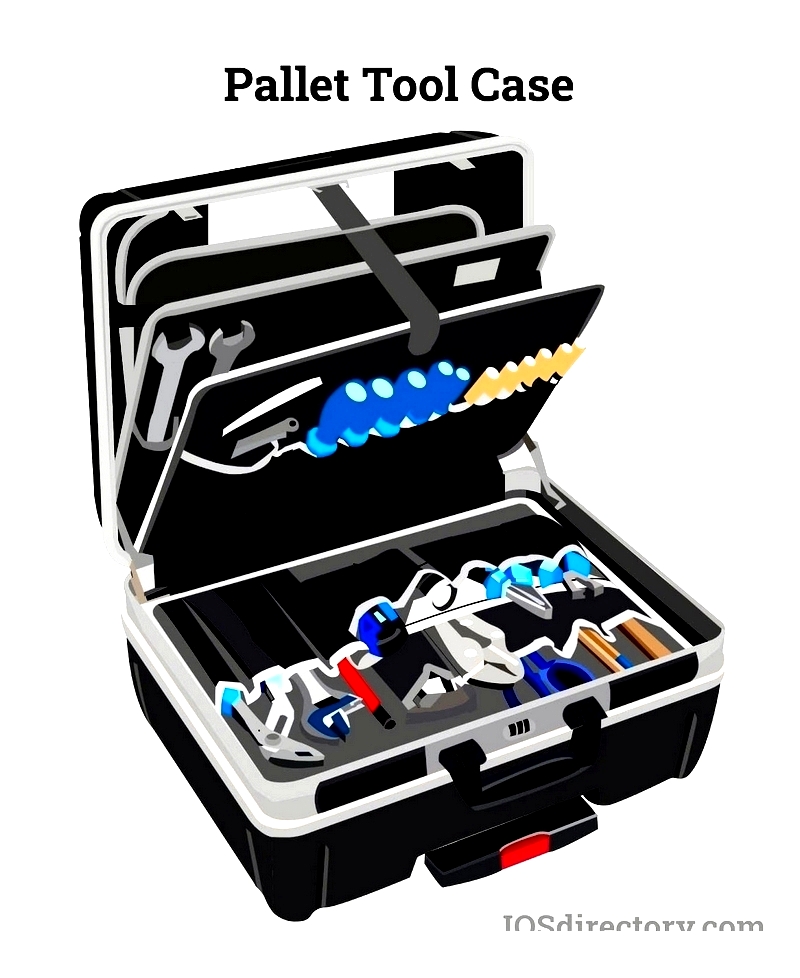

Pocket Pallet

Pocket pallet cases are growing in popularity due to their ample storage capacity. Their interior accommodates multiple pallets for organized tool storage by function, typically secured to the lid with a latch.

Available in various styles, some handle large tools for major projects while others organize precision instruments for delicate work.

The image below shows pallets arranged in both the lid and main compartment, with removable pallets maintaining tool organization.

Protector

Protector cases are waterproof, crush-resistant, and impact-proof, sealing out contaminants. Made from wood, plastic, or metal, they withstand harsh conditions while remaining lightweight. To qualify as protector cases, they must pass rigorous tests including water immersion, temperature extremes, and drop tests.

Available in various materials like aluminum and steel, they range from simple models to complex designs with additional storage features. Interior padding protects sensitive instruments from damage, making these cases the most durable option available.

Road

Road cases are built for travel with rugged materials that withstand airline handling. Made of metal with reinforced corners and secure latches, they must meet Air Transport Association standards.

Available in various sizes, many feature wheels for easier transport.

Rolling

Rolling cases are among the most durable options, typically made from high-density polyethylene. They offer various interior configurations including pockets, compartments, and foam inserts.

Ideal for transporting heavy equipment, most feature ribbing for added strength.

Soft Side

Soft-sided cases have grown popular for being unbreakable, tear-resistant, and durable. They feature pockets, pallets, loops, and compartments in moisture-repellent, shock-resistant materials.

Despite being lightweight, they withstand wear comparable to hard cases. Their flexible material adapts under pressure while protecting tools with padding.

Super-Sized

Extra-large cases offer exceptional strength and storage capacity. Their size allows for additional features, with piano hinges and side supports for stability.

Typically featuring locking systems, they're made from durable plastics, aluminum, or steel.

The cases mentioned represent just a fraction of available options. Each industry can find cases tailored to specific needs, with manufacturers often offering customization.

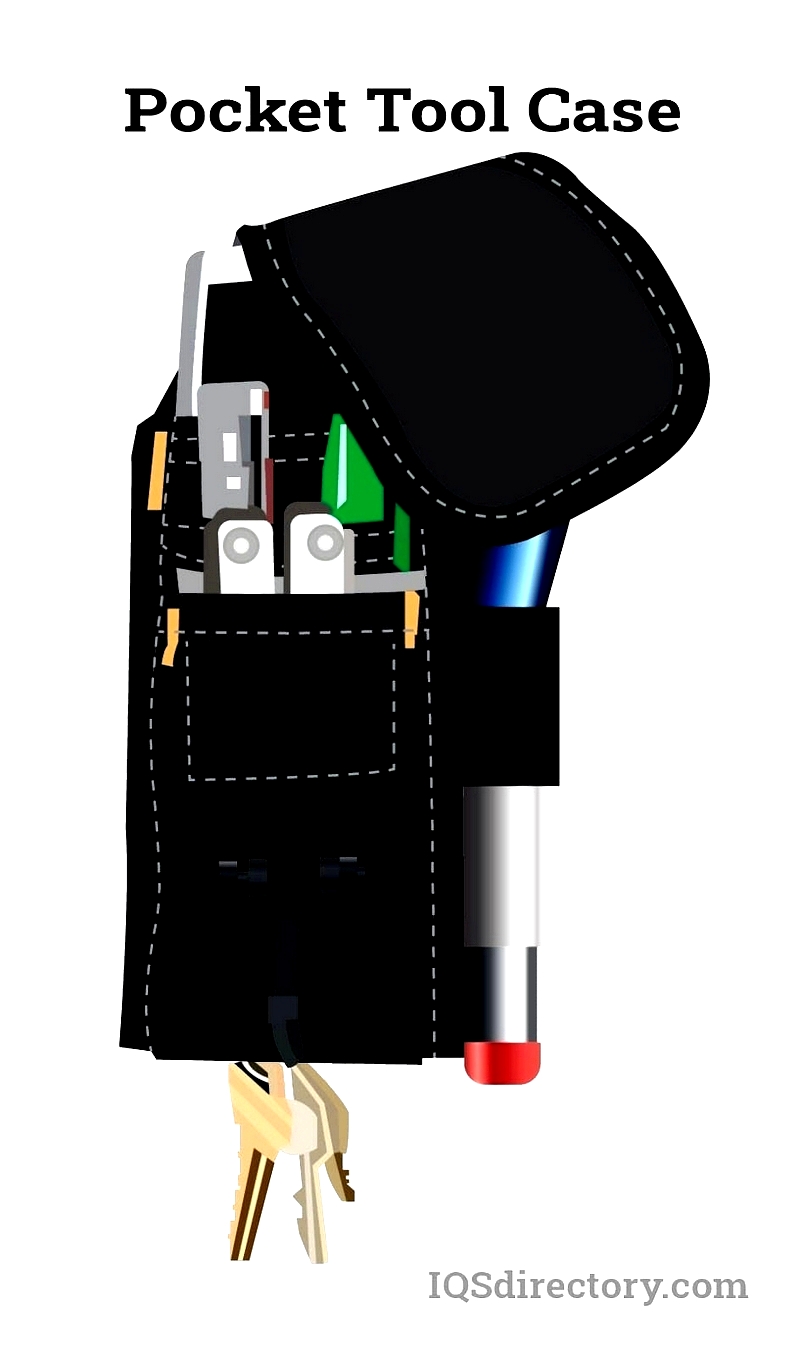

Pocket cases provide convenient storage for small items like precision tools and components. They can attach to belts, fit in pockets, or strap to arms, organizing tools for delicate work on electronics.

Available with 5-20+ pockets, they keep tools accessible and organized, saving time during precision tasks.