Introduction

This article provides a comprehensive overview of extruded rubber.

You'll discover detailed information on the following topics:

- Understanding Extruded Rubber

- Popular Extruded Rubber Products

- Materials Used in Rubber Extrusion

- The Rubber Extrusion Manufacturing Process

- Additional Key Information

Chapter 1: What is Extruded Rubber?

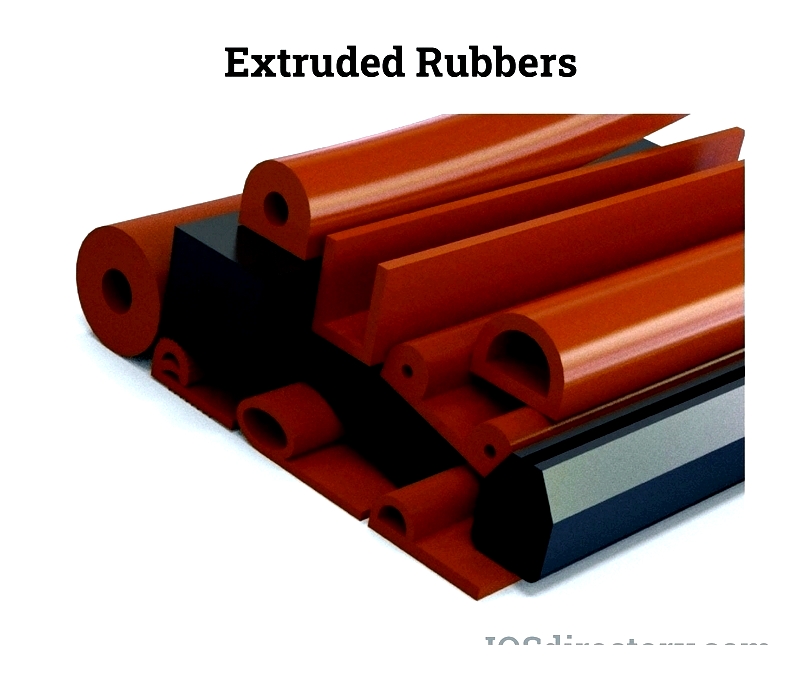

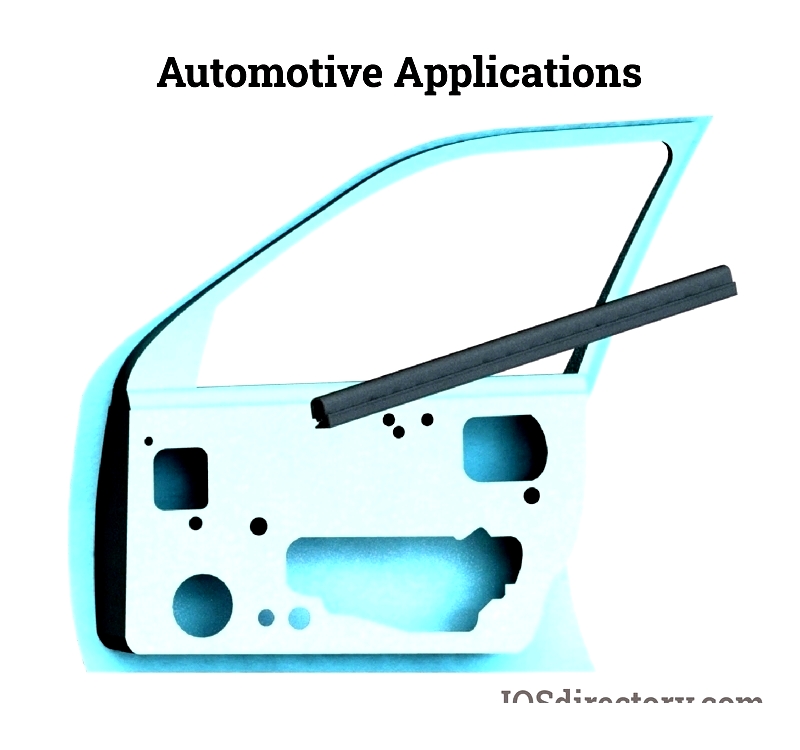

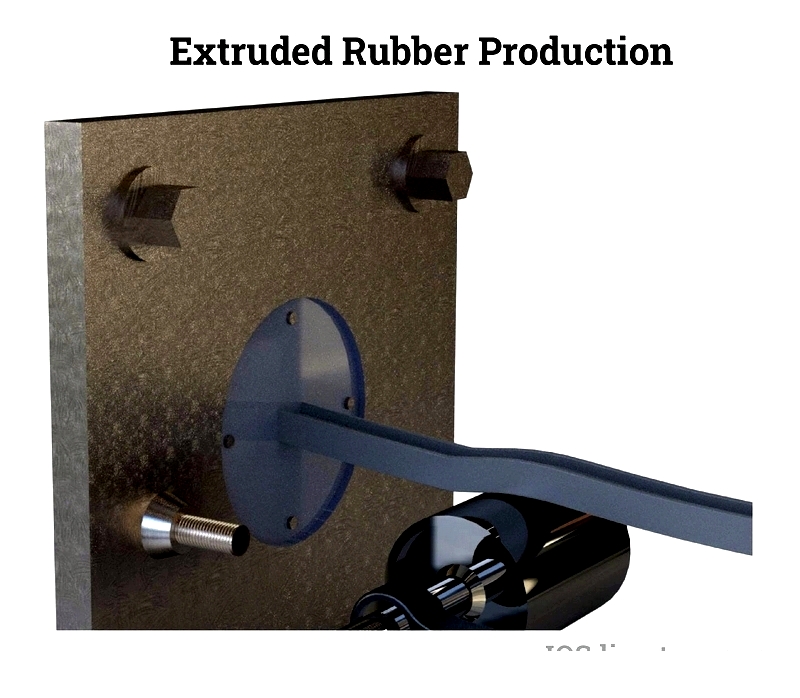

Extruded rubber describes products created by heating and pressurizing elastomer compounds before forcing them through a specially shaped die. This manufacturing technique produces continuous materials with uniform cross-sections. The die's design determines the profile shape, with numerous configurations serving industries like automotive, aerospace, electronics, construction, and consumer goods.

Chapter 2: Benefits of Extruded Rubber

Rubber extrusion stands as a crucial industrial process for creating consistent shapes and custom profiles efficiently, with minimal waste and competitive pricing. These products are valued for their durability, long service life, and dependable performance under challenging conditions. They demonstrate excellent resistance to chemicals, temperature extremes, UV exposure, impact, wear, and environmental factors—qualities that make extruded rubber ideal for seals, gaskets, tubing, and profiles across multiple sectors.

Originating in the 1930s, extrusion technology initially produced continuous-profile items like rods, pipes, and weatherstripping. Modern advancements now enable manufacturing diverse materials including thermoplastics, metals, and various rubber compounds. This versatile process creates precision components for automotive, aerospace, marine, and OEM applications while accommodating unique customer specifications.

Rubber's natural elasticity allows compounding with additives to achieve specific properties like enhanced strength, flexibility, or chemical resistance. Similar to engineered plastics, rubber offers lightweight durability and can form complex profiles using specialized dies. Requiring less processing energy than other materials, extruded rubber maintains all the benefits of premium rubber products at lower costs, regardless of compound type.

Contemporary manufacturing techniques enable co-extrusion of rubber with plastics, combining materials' strengths in single products. This innovation merges thermoplastic elastomers' flexibility with rigid plastics' structural integrity, creating cost-effective solutions for demanding sealing and weatherproofing applications.

Rubber extrusion delivers significant manufacturing and performance advantages. The process yields high-quality custom profiles, gaskets, seals, and weatherstripping with design flexibility, reduced waste, and increased production efficiency. These benefits translate to faster turnaround, lower costs, and optimal solutions for sealing, insulation, and protective applications.

Benefits of Extruded Rubber

Superior Quality – Extruded rubber products offer consistent performance with outstanding resistance to temperature extremes, UV radiation, friction, and wear, making them ideal for demanding applications.

Exceptional Resistance – Engineered to endure harsh conditions, these components resist chemical, oil, and environmental degradation, ensuring longevity in critical applications.

Cost Savings – The efficient extrusion process minimizes material waste, delivering affordable solutions for both mass production and custom orders.

Product Diversity & Customization – Manufacturers can create virtually any profile, from simple seals to complex multi-material designs, meeting specialized requirements across industries.

Fast Turnaround & Scalability – Modern extrusion systems enable rapid production, adaptable batch sizes, and quick tooling changes to meet market demands.

Eco-Friendly Manufacturing – Reduced material consumption and waste support sustainable production practices.

For custom rubber solutions, partnering with experienced extrusion specialists ensures access to material expertise, design support, and value-added services like cutting and splicing for optimal product performance.