Introduction

This article provides information about chillers, their various types, and how they function.

You will learn about:

- What a Chiller is

- Chiller Applications

- Chiller Working Principles

- Different Chiller Types

- Laser Chillers and Their Operation

- And more...

Chapter One – What is a Chiller?

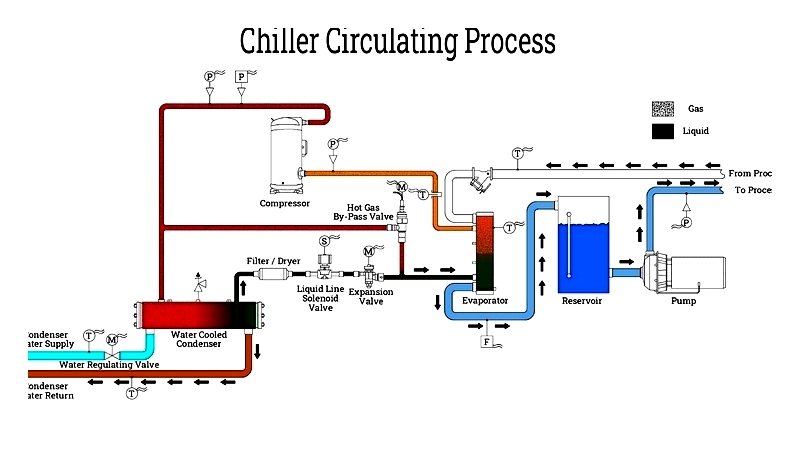

A chiller is a cooling system designed to remove heat by circulating refrigerant through various components where thermal energy is transferred and expelled. The key components of an industrial chiller include a compressor, condenser, expansion valve, and evaporator. These elements work together to efficiently circulate refrigerant, effectively removing heat from processes, operations, or environments.

Industrial chillers come in different types, each using distinct heat extraction methods. They utilize either air or water as cooling mediums. For instance, air-cooled chillers employ fans to dissipate heat, while water-cooled chillers use cooling towers to circulate water for heat removal.

Beyond cooling methods, industrial chillers are also classified by compressor type. While all compressors serve the basic function of compressing refrigerant to increase its temperature and pressure before reaching the condenser, they employ different designs and operating mechanisms to achieve this.

Industrial chillers operate on vapor compression or absorption principles. They are specifically designed to provide continuous coolant flow for temperature maintenance. This steady temperature control is achieved through a circulating fluid system that effectively lowers temperatures by extracting heat.

Chapter Two - Industrial Chiller Applications

Industrial chillers are vital cooling systems used across numerous industries to regulate and stabilize process temperatures. Operating on vapor compression or absorption principles, they deliver a continuous flow of coolant—typically water, brine, or glycol-water solutions—to maintain precise temperatures. By circulating chilled fluid through closed-loop systems, chillers efficiently transfer heat away from machinery, materials, or environments, ensuring operational stability and energy efficiency.

Since the 1950s, advancements in chiller design and refrigeration technology have transformed industrial cooling solutions. Early water baths have been replaced by sophisticated liquid chillers capable of meeting demanding industrial requirements in laser cutting, die casting, medical imaging, and chemical manufacturing. Today, chillers are indispensable in modern manufacturing, enhancing productivity and product quality across countless applications.

Industrial Chiller Uses

Industrial Applications

Most industrial operations generate significant heat from high-powered machinery, furnaces, injection molding equipment, presses, milling machines, and ovens. Modern chiller systems circulate cooled water or process fluid through heat exchangers to prevent overheating and minimize downtime. By maintaining optimal temperatures, chillers extend equipment lifespan, reduce maintenance costs, and improve energy efficiency and productivity.

Work Environment and Facility Cooling

Manufacturing plants often accumulate substantial heat from continuous equipment operation, creating uncomfortable or unsafe conditions. To ensure worker safety and comfort, facility managers deploy chilled water systems or HVAC chillers with air handling units to distribute cooled air. Air-cooled chillers offer flexible installation options on rooftops, in mechanical rooms, or near buildings. Advanced temperature control systems precisely manage climate conditions, reducing heat stress and improving operational performance.

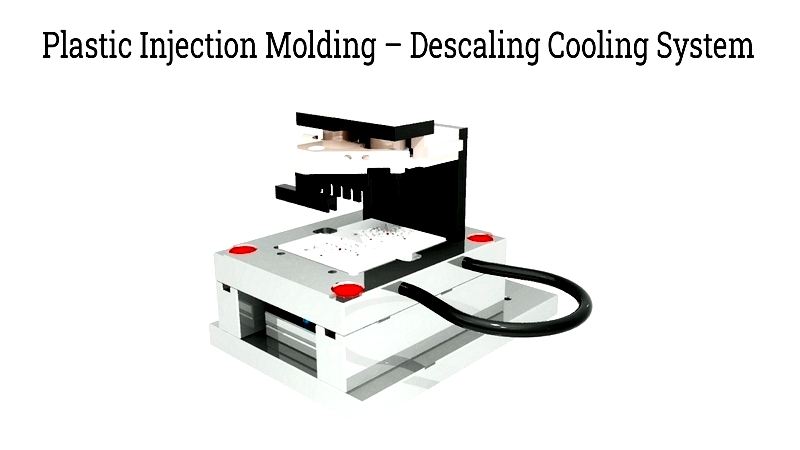

Plastic Manufacturing and Injection Molding

In plastic manufacturing—particularly injection molding, blow molding, and extrusion—precise temperature control is crucial for product consistency and dimensional accuracy. Industrial chillers provide controlled cooling through heat exchangers to remove waste heat from molds and extrusion lines. Proper cooling maintains cycle efficiency and material integrity, directly impacting product quality in automotive, consumer goods, and other applications.

metal Plating, Anodizing, and Surface Treatment

metal finishing processes like electroplating, anodizing, and chemical etching generate intense heat in chemical baths. Industrial chillers integrate with plating lines to remove excess heat through external heat exchangers. Precise temperature control ensures consistent coatings, chemical stability, and improved production yields in metal finishing operations.

Food and Beverage Production

The food and beverage industry requires strict temperature control for storage, fermentation, pasteurization, and packaging. Glycol or water-cooled chillers are commonly used in bakeries, breweries, and food processing to maintain quality and extend shelf life. These chillers help comply with health and safety regulations while preserving product integrity.

Power Generation and Energy Sector

Power plants produce significant waste heat during generation. Industrial chillers and cooling systems remove heat from turbines, generators, and electrical components. By efficiently dissipating heat, chillers protect sensitive equipment and ensure reliability in critical power generation environments.

Medical Industry and Laboratory Cooling

Healthcare facilities and laboratories rely on chillers to maintain precise temperatures for medical equipment and biological samples. Chillers regulate temperatures in MRI scanners, CT scanners, and laboratory incubators, ensuring accurate diagnostics and equipment protection.

Pharmaceutical Manufacturing

The pharmaceutical industry uses process chillers for temperature control during chemical synthesis, crystallization, and storage. These chillers—available in various types—ensure sanitary operation and compliance with cGMP and FDA regulations. They prevent contamination and maintain consistent clinical outcomes.

Laser Cooling and Precision Equipment

Industrial laser systems require precise temperature management for optimal performance. Laser chillers provide closed-loop water cooling to absorb waste heat and maintain laser source stability. These chillers prevent thermal damage and reduce maintenance, supporting consistent productivity in manufacturing and medical applications.

Temporary Chiller Systems and Rental Solutions

Construction, events, and facility upgrades often require temporary cooling solutions. Portable chillers provide heating, ventilation, and cooling during shutdowns, demand spikes, or equipment failures. Available as air-cooled or water-cooled units, they offer flexible capacity and rapid deployment to maintain optimal conditions with minimal disruption.

There are three primary uses for temporary HVAC systems:

- Heating and Dehumidification: Essential for new construction in cold weather, HVAC replacement, or heating failures. Critical for humidity control in data centers and sensitive environments.

- Vent