Introduction

This article offers comprehensive details about finishing machines.

It explores the following topics:

- What are Finishing Machines?

- metal Finishing/Polishing Approaches

- Types of metal Finishing/Polishing Processes

- Varieties of Finishing/Polishing Machines

- Specialized Surface Finishing Equipment

- Choosing the Appropriate Finishing Process

- Selecting the Right Deburring and Finishing Machine

- And additional relevant information

Chapter 1: What are Finishing Machines?

Finishing machines serve in the final phase of metal fabrication, concentrating on perfecting metal surfaces. This stage targets achieving smooth, polished results through various materials and techniques like tumbling media, plating, and loose abrasives that refine the metal's surface.

metal finishing encompasses multiple procedures that clean, polish, and enhance metal surfaces, including electroplating and other methods that improve both appearance and functionality. The industry utilizes diverse processes, each providing unique benefits for surface treatment.

Various machines with differing capabilities and efficiencies are used in metal finishing. Their performance depends on size and capacity. This article examines key finishing machine types, emphasizing their distinctive features and uses.

Standard Features of Finishing Machines

- Effective motor positioning minimizes vibration

- High-tensile nut bolts ensure durability

- Efficient process fluid removal guarantees superior surface finishing

- Energy-efficient motor design

- Shot-blasted bowls before and after polyurethane lining for painting

- Smoothly ground internal welds

- Anti-rotation motor locking plate included

- Stress relief process for bowls

Benefits of metal Finishing

Surface finishing provides several advantages:

- Reduces corrosion effects

- Creates paint-adhesive surfaces

- Strengthens products by increasing deformity resistance

- Protects against friction-induced wear

- Enhances visual appeal

- Prevents surface defects

Chapter 2: Approaches to metal Finishing and Polishing

Various methods achieve metal finishing, as described below.

metal Polishing

metal polishing smooths surfaces using abrasives, removing imperfections to create shiny, reflective finishes. Often combined with gentler buffing, it not only improves appearance but also removes subsurface oxidation, preventing corrosion and extending metal lifespan.

metal Polishing Process

The process uses different abrasives selected according to material. Unfinished materials require multiple stages: coarse abrasives first remove imperfections, followed by progressively finer abrasives for refinement.

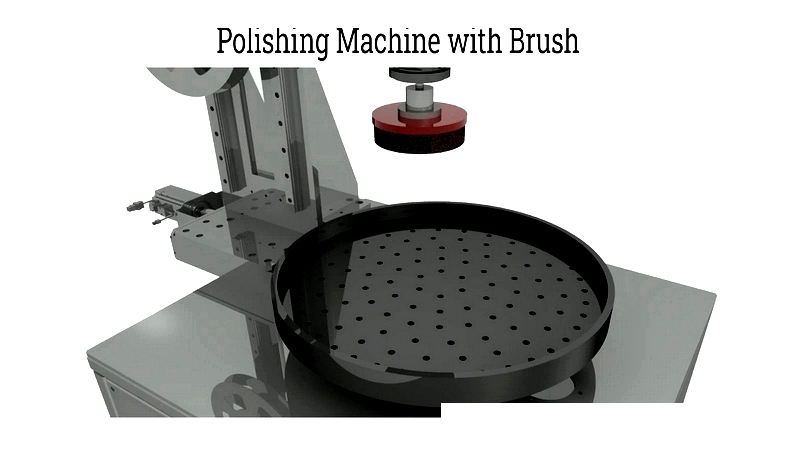

Buffing and polishing compounds with polishing wheels achieve mirror-like finishes. While typically applied dry, lubricants like kerosene or wax may be used. Die grinders, stationary polishers, or specialized equipment enhance shine during buffing.

Softer metals like brass use fine copper-plated grits for smooth surfaces, buffed with airflow mops. Different tools require specific polishing techniques: grinding wheels initially rough out tools, followed by dry polishing materials, with optional grease application for additional polishing.

Polishing improves surface quality by reducing friction and wear, enhancing tool performance and longevity.

Abrasives Used in Polishing

Abrasive selection depends on metal strength. Lower tensile strength metals (copper, brass, aluminum) use gray silicon carbide, also suitable for cemented and gray iron carbide.

Higher tensile strength metals (carbon/alloy steel, non-ferrous metals, iron alloys) use white/gray aluminum oxide. Green chromium oxide works specifically for ferrous metals like steel.

Common polishing materials include leather, canvas, felt, plastic, wool, and rubber. Buffing wheels typically use cotton or wool cloth.

Polishing Applications

Manufacturing relies on polishing for kitchenware, cookware, automotive parts, and architectural metals. It also refurbishes metal components when necessary.

Buffing and polishing enhance workplace safety by preventing corrosion in plumbing systems and eliminating mold/bacteria in pharmaceutical and dairy industry pipes.

metal Smoothing

Mass finishing creates extremely flat surfaces. Bearing surfaces benefit from smoothing that reduces noise and abrasion while maintaining oil-retaining valleys. This process extends tool lifespan by minimizing wear.

Smoothing achieves Ra values as low as 0.01 µ consistently, primarily used in:

- Automotive - gear wheels, camshafts, drive units

- Motor Racing - valves, gear wheels, pistons, camshafts

- Forming Tools - forming and pressing surfaces

- metalworking - high-speed spindles

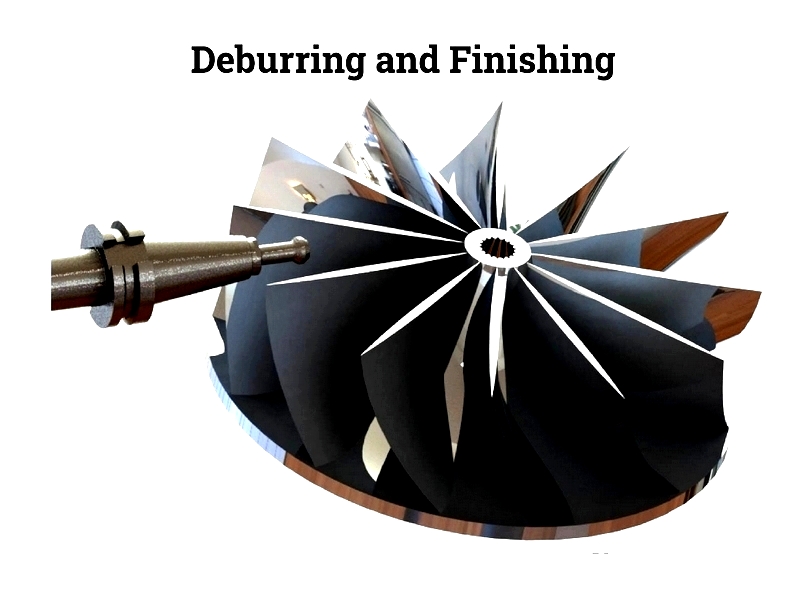

Deburring and Finishing

Deburring and surface finishing machines excel at mass finishing for plastic, rubber, ceramic, and metal parts, ensuring consistent, reliable results.

Wet Finishing

Optimal surface quality requires matching appropriate process media with machines. Wet finishing typically uses water/compound mixtures that absorb and wash away debris, maintaining efficiency and preventing media clogging.

Dry Finishing

Proper process and medium selection is crucial. Dry finishing operates without liquids, requiring powerful extraction units when using dry abrasive granulates. This method often involves polishing pastes/powders where friction between medium and workpiece creates polished surfaces.

Differences Between Finishing, Polishing, and Buffing

While both use abrasives, finishing removes scratches/imperfections from cutting/grinding, while polishing adds glossy appearances.

Polishing uses abrasive belts; buffing employs compound-treated cloth wheels. Polishing creates brushed finishes; buffing produces lustrous finishes and removes remaining lines, typically following polishing.

Polishing levels surfaces using abrasive discs/belts to eliminate scale, pits, and scratches. Buffing then removes polishing lines. Finest abrasives correct levels, welds, and imperfections before scratch line removal.

Buffing employs rotating cloth wheels with fine abrasive compounds to create bright finishes. The buff wheel carries greaseless compound-based matrices that perform the actual finishing.