Introduction

This article provides a detailed examination of tamper-proof bags.

It covers the following topics:

- What are Tamper-Proof Bags?

- Evidence Bags and Their Uses

- Tamper-Proof Bags With Bubble Wrap

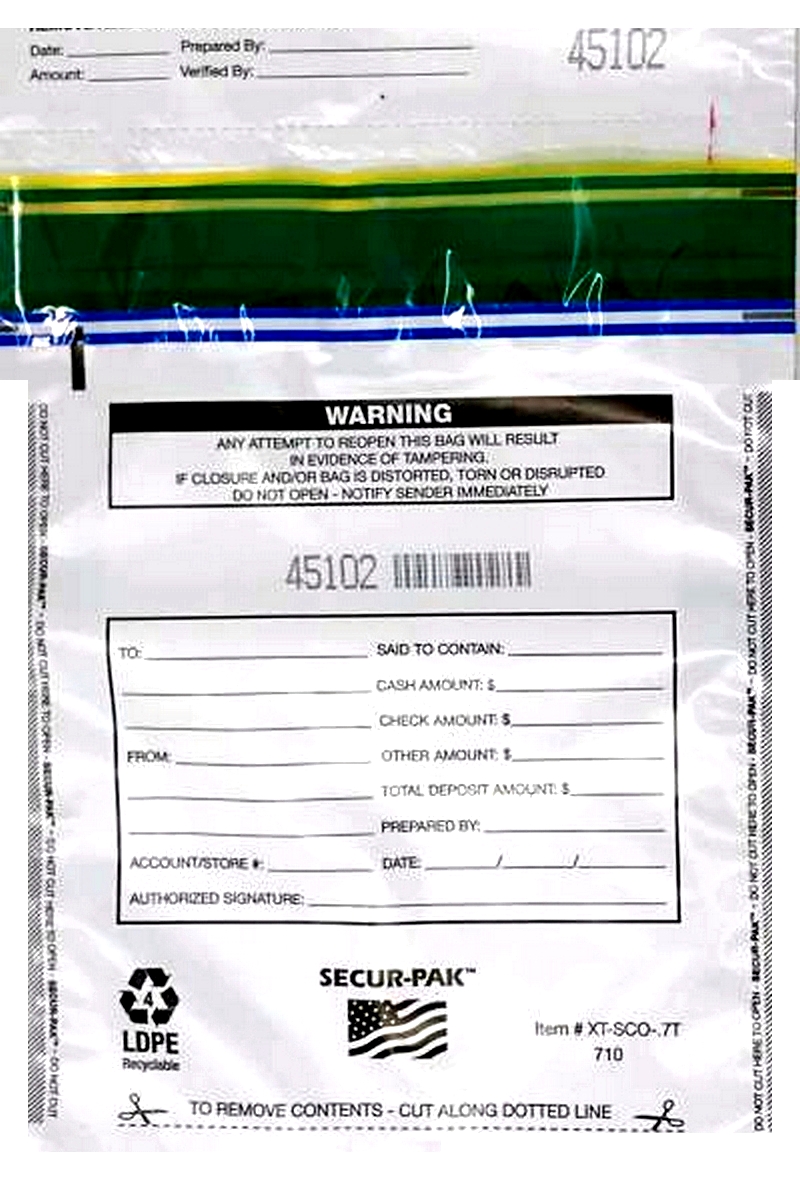

- Deposit Bags

- Bank Coin Bags

- Bank Deposit Bags

- Zippered Bank Deposit Bags

- Differences Between Tamper-Proof and Tamper-Evident Bags

- And Much More...

Tamper Proof Bags by Connover Packaging

Tamper Proof Bags by Connover PackagingChapter 1: What are Tamper Proof Bags?

Tamper-evident bags play a crucial role in securing crime scene evidence. Constructed from durable, leak-resistant polyethylene, these bags resist tears and punctures while featuring strong adhesive seals to securely contain their contents.

In modern eCommerce, courier bags have become essential. Tamper-proof courier bags provide businesses with professional, secure packaging solutions that optimize shipping and storage processes. Courier services and logistics providers frequently use these bags to transport semi-fragile items including electronics, jewelry, and watches.

Self-adhesive or heat-seal technologies enhance sealing efficiency, while integrated pod jackets eliminate the need for separate document attachments. This creates cost-effective solutions for bulk custom designs. Additionally, courier bags serve as excellent branding tools, allowing direct printing of promotional content to increase brand visibility.

Tamper-proof courier bags feature hot-melt adhesive strips that prevent undetected opening. Made from co-extruded film, these recyclable bags resist oils, water, and rough handling. A clear pod jacket on the back provides convenient space for waybills, addresses, and important documents.

Chapter 2: What are Evidence Bags and How Are They Used?

Evidence bags serve as specialized containers for collecting, transporting, and preserving physical evidence in forensic investigations and legal proceedings. Manufactured from high-quality paper or durable plastic, these bags protect various evidence types while maintaining integrity crucial for court admissibility.

Modern evidence bags feature writable panels for recording chain of custody details, including case information, collection details, and recovery locations. Proper documentation ensures secure handling and prevents tampering allegations in legal processes.

Forensic best practices recommend storing individual items separately to minimize cross-contamination. While similar items may be grouped, most evidence requires separate bags with unique identifiers for accurate tracking during analysis and court presentation.

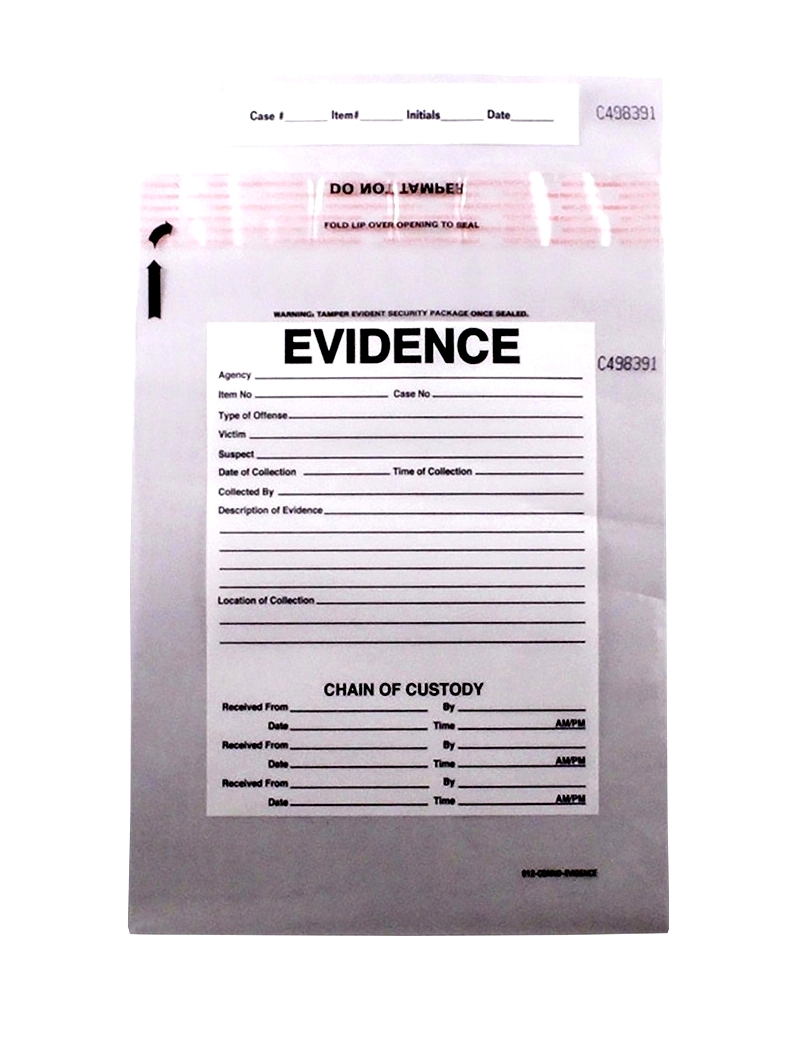

Crime Scene Evidence Bags

These translucent or opaque bags feature tamper-evident seals to maintain evidence integrity from crime scenes to courtrooms. Resealable options allow secure access during investigations.

Crime Scene Evidence Bags by Connover Packaging

Crime Scene Evidence Bags by Connover PackagingForensic Bags

Designed for complex evidence like DNA and fingerprints, these airtight bags may include separate compartments for different sample types, protecting against contamination during storage.

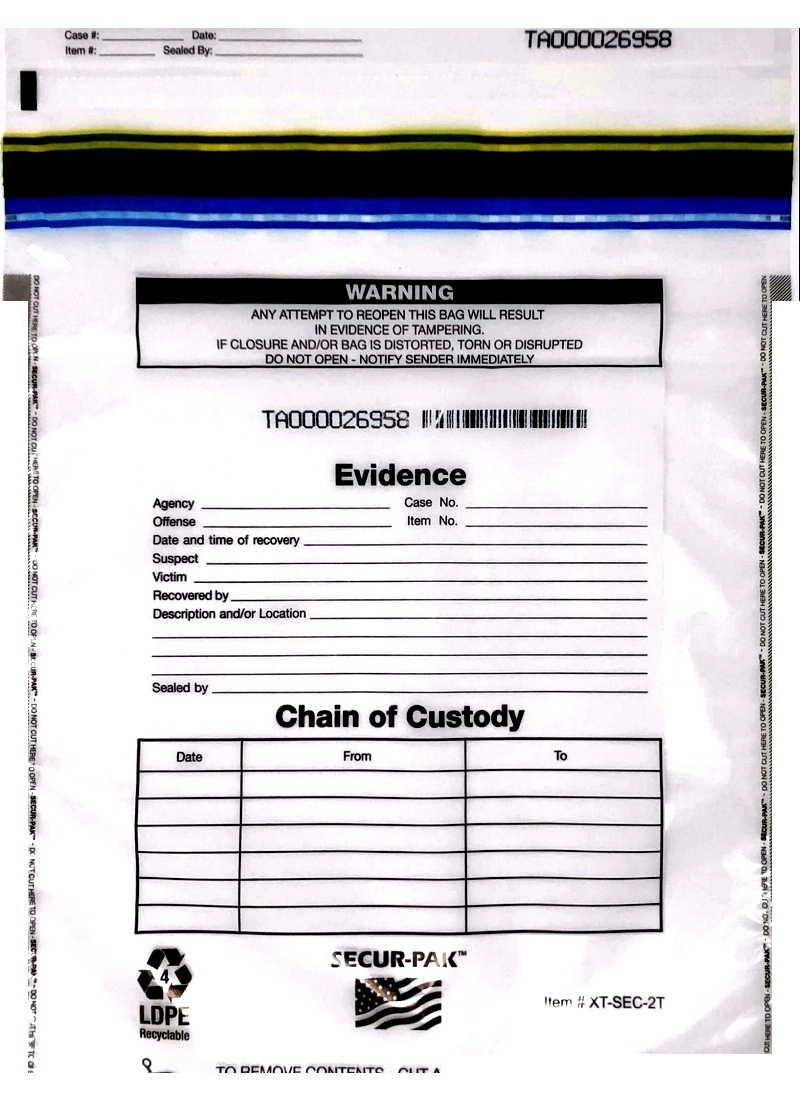

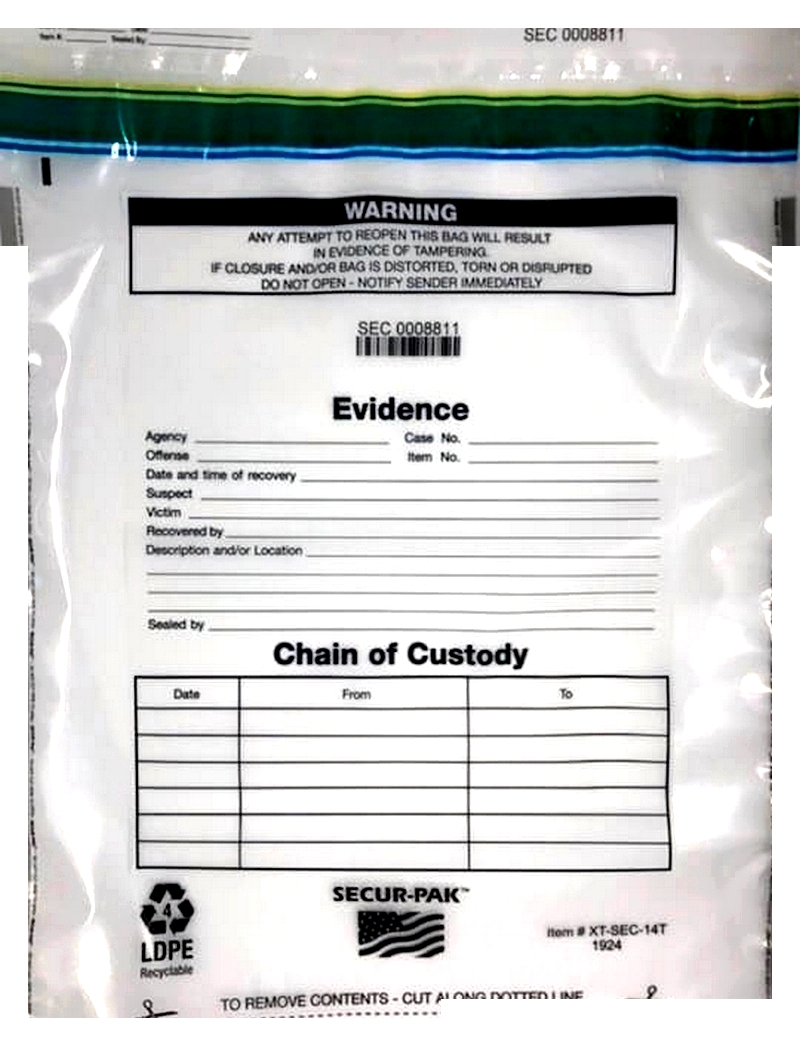

Chain of Custody Bags

Used by law enforcement, these specially marked bags maintain documented handling records, serving as legal safeguards against evidence mishandling throughout investigations.

Chain of Custody Bags by Connover Packaging

Chain of Custody Bags by Connover PackagingTamper-Proof Evidence Bags

Industry-standard bags made from tear-resistant materials with self-sealing closures prevent unauthorized access and contamination of forensic samples.

Tamper Evident Bags by Connover Packaging

Tamper Evident Bags by Connover PackagingTamper-evident mailers with tracking codes provide visible tampering indicators for sensitive items in legal, medical, and banking applications, ensuring compliance with custody regulations.

Features/Advantages of Tamper-Proof Bags:

- Ideal for secure shipping of forensic materials and sensitive cargo

- Glossy exterior with opaque interior for content privacy

- Streamlined tape wrapping for efficient packaging

- Peel-and-seal closures minimize human error

- Lightweight construction reduces shipping costs

- Irreversible adhesive seals show tampering attempts

- Custom printing options for agency identification

- Adjustable thickness to meet security standards

- Cost-effective alternative to rigid containers

- Reinforced seams prevent accidental rupture

- Engineered closures support forensic protocols

- Suitable for non-fragile items and documents

- Tear strips facilitate authorized access

- Customizable colors for different case types

- Integrated document pouches for secure attachments

- Tamper-evident indicators for high-value items

- Eco-friendly recyclable materials

- Custom dimensions to meet operational needs

Reasons for Using Tamper-Evident Bags (TEB)

Law enforcement and forensic labs require TEBs to securely handle evidence during investigations. These bags:

- Maintain chain of custody from collection to courtroom

- Ensure reliable evidence presentation in legal proceedings

Proper storage preserves evidentiary value and prevents contamination throughout investigations.

How to Use a TEB

Proper evidence handling begins with protective equipment. Forensic professionals should:

- Work in clean, controlled environments

- Use sanitized surfaces to prevent contamination

When inserting items, expand the bag and turn it inside out to handle evidence without touching the exterior. After placement, arrange contents for visibility and seal securely while documenting all procedures.

How to Seal a TEB

Follow these steps for proper sealing:

- Place the TEB on a clean surface

- Hold the orange security strip edge

- Peel back the blue strip to expose adhesive

- Press the strip firmly for complete bonding

document the sealing process with time, date, and responsible personnel information.

When to Use a TEB

Use TEBs for all seized property and evidence collection, especially in cases requiring strict chain of custody. Handling protocols include:

- Special containers for oversized items

- Puncture-proof secondary packaging for sharp objects

- Paper bags for clothing preservation

- Double-bagging for cash and biological samples

- Breathable bags for moist evidence

Complete all documentation fields and use digital tracking to ensure court compliance with evidentiary standards.