Introduction

This page offers comprehensive information about plastic extrusion. As you read through the article, you'll discover details on:

- Plastic Extrusion Overview

- Basic Screw Extrusion Process

- Extruder Types

- Components of Single Screw Extruders

- Various Die Types

- Plastic Extrusion Applications

- And more…

Chapter One – What is Plastic Extrusion?

Plastic extrusion, also called plasticating extrusion, is a continuous, high-volume manufacturing process. Thermoplastic materials in powder, pellet, or granule form are melted uniformly and forced through a shaping die under pressure. In screw extrusion, pressure is generated by the screw rotating against the barrel wall. The molten plastic takes the die's shape as it exits, becoming the extrudate.

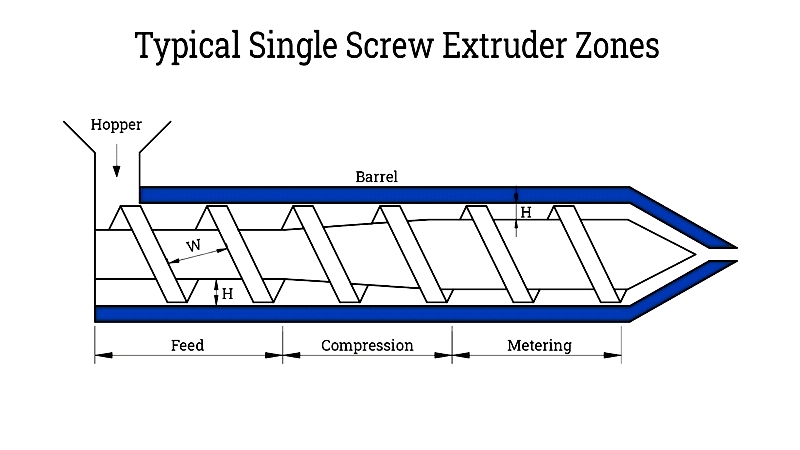

An extruder typically consists of four distinct zones:

Feed Zone

This zone maintains a constant flight depth, which measures the distance between the screw flight's major and minor diameters.

Transition Zone or Compression Zone

Here, flight depth decreases, compressing the thermoplastic material and initiating plasticization.

Mixing Zone

Flight depth stabilizes in this section, where specialized mixing elements ensure complete melting and uniform blending.

Metering Zone

Flight depth reduces further but remains consistent, with pressure driving the molten material through the forming die.

Polymer melting occurs through three primary mechanisms:

Heat Transfer

Energy transfers from the extruder motor to its shaft, with screw profile and material residence time affecting the melting process.

Friction

Internal resistance within the powder, influenced by screw profile, speed, and feed rate, generates frictional heat.

Extruder Barrel

Multiple independent controllers regulate barrel temperature to maintain stable processing conditions.

Chapter Two - Leading Plastic Extrusion Machines

The U.S. and Canada offer diverse plastic extrusion machines for high-quality production. These advanced systems enable efficient manufacturing of plastic products through profile, pipe, sheet, and film extrusion. They serve key industries including construction, automotive, packaging, and consumer goods, driving economic growth and manufacturing innovation. Machine selection depends on application requirements like throughput, material compatibility (PVC, HDPE, PET), and automation levels. Below are leading machines known for efficiency, precision, and innovation.

Davis-Standard DS-RE Extruders

Renowned for versatility and energy efficiency, these industry-leading single and twin-screw extruders handle various thermoplastics. Advanced controls and customizable configurations ensure consistent output and reliable performance.

Cincinnati Milacron Extrusion Machines

Specializing in profile, pipe, and sheet production, these machines offer precision extrusion controls and advanced temperature regulation. Robotic solutions enhance productivity with rapid changeovers and modular designs.

Milacron PAK Series

High-performance extruders for tubing, film, and specialized profiles, featuring energy-efficient operation and extensive customization options for single or multi-layer co-extrusion.

KraussMaffei Berstorff Extrusion Lines

Internationally recognized for precise temperature control and robust construction, these machines excel in complex extrusions like large-diameter pipes and multilayer sheets.

NFM/Welding Engineers, Inc. Extruders

Specialized in durable, precision extrusion technology for various plastic processing needs, these systems support diverse materials and applications.

Selecting the Right Machine

Consider material compatibility, extrusion rate, control precision, energy efficiency, and technical support. Leading manufacturers provide ongoing service and parts availability to maximize operational efficiency.

The plastic extrusion industry continues evolving with new technologies and manufacturers. Stay informed through industry publications and manufacturer resources for the latest trends and specifications.

Chapter Three – The Basic Screw Extrusion Process

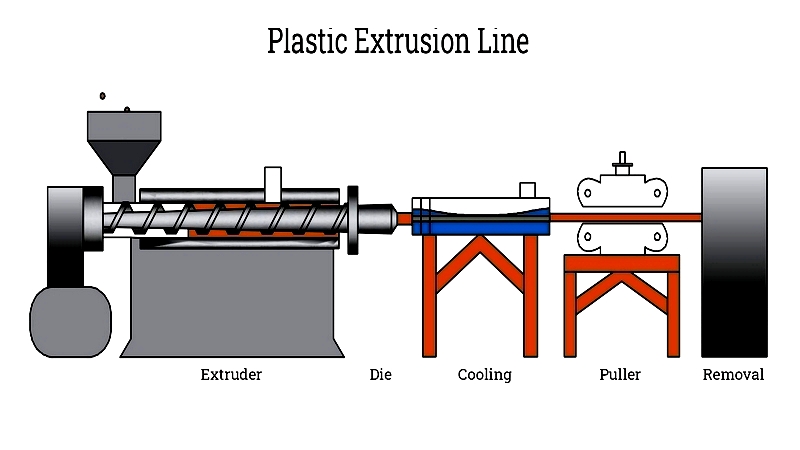

This fundamental plastic manufacturing method produces continuous profiles like pipes, tubing, films, and sheets. The process begins with blending polymeric feedstock with additives including stabilizers, colorants, flame retardants, fillers, lubricants, and reinforcements to optimize properties.

Hygroscopic resins (PET, nylon, ABS) require drying to prevent degradation and defects. Even non-hygroscopic materials may need drying when moved from cold storage to prevent condensation.

The prepared material enters the feed hopper, where consistent feeding ensures optimal melting and process efficiency. Flow issues with powders or pellets may require inert gas injection to prevent hopper buildup.

Inside the extruder, material moves through the screw-barrel annulus, experiencing increasing friction and shear forces that facilitate mixing and melting. Temperature-controlled zones (feed, transition, metering) progressively plasticize and homogenize the resin.

The molten polymer passes through a screen pack to remove contaminants before entering the shaping die. After forming, the extrudate cools via water or air systems, then may undergo additional treatments like flame treatment, cutting, or annealing.

Quality control verifies dimensions, surface finish, and mechanical properties before packaging. ongoing advancements in screw design, automation, and process control continue improving extrusion efficiency and product quality across industrial applications.