Introduction

This article provides an in-depth exploration of depalletizers.

By reading this article, you'll gain insights into key topics including:

- What Depalletizers Are

- How Depalletizers Work

- Key Selection Factors for Depalletizers

- Different Types of Depalletizers

- Components of a Depalletizer

- Depalletizer Applications

- Pros and Cons of Depalletizers

- And more...

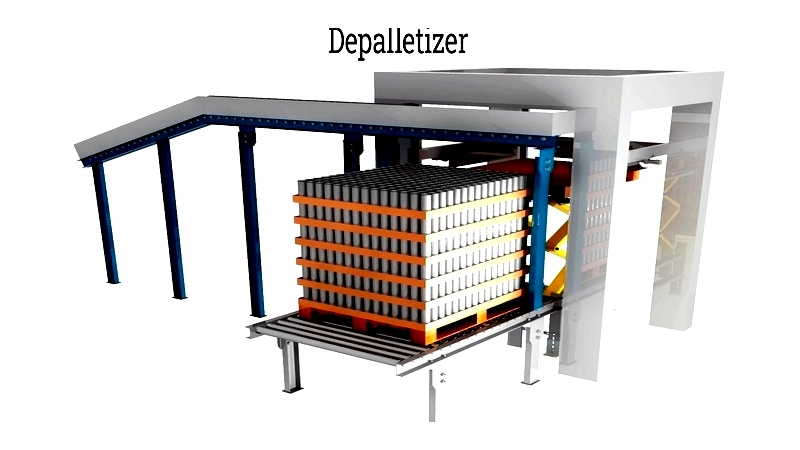

Depalletizer By Toptier Palletizers

Depalletizer By Toptier PalletizersChapter 1: Understanding Depalletizers, Their Functionality, and Selection Criteria

What are Depalletizers?

While palletizing involves arranging items on pallets, depalletizing systematically unloads them. Pallets are flat platforms designed for secure transportation of multiple items. Depalletizers efficiently unload these pallets at their destination, handling various products like cans, bottles, boxes, and shrink-wrapped packages. These machines streamline product transfer from pallets to other processes, ensuring stability and optimized handling.

By automating unloading, depalletizers eliminate manual labor, saving time and costs. They're crucial in distribution operations, enhancing logistics speed and reliability. Modern depalletizers feature control systems tracking product details and operational parameters for safe handling. Many can lift entire product layers quickly, while advanced models with vision systems handle mixed pallets precisely.

Available in various designs, depalletizers are selected based on material handling needs. They use pneumatic systems, vacuum chambers, or mechanical gripping to lift items. These machines boost efficiency in warehouses and manufacturing, offering flexibility and labor cost reduction.

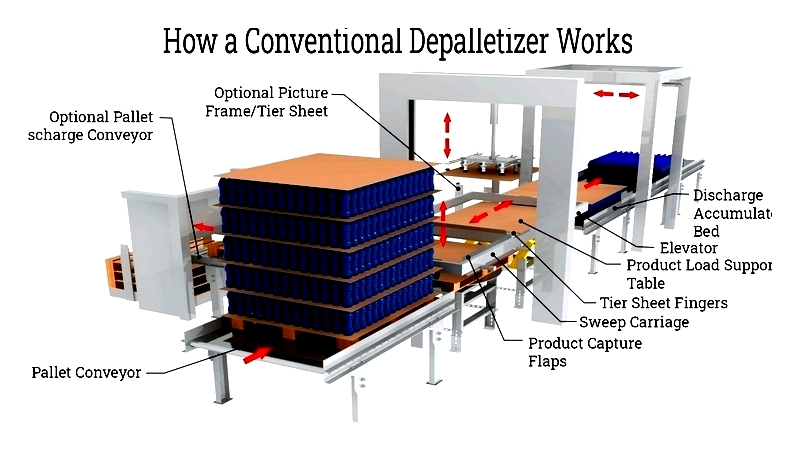

How Depalletizers Operate

Depalletizers share core features across applications. They typically include an adjustable-height conveyor system with key components: supply conveyor, operation deck, load transfer station, and PLC-controlled hub. Handling diverse products in distribution centers presents challenges that depalletizers address through customization for specific length, height, and routing requirements.

After plastic wrapping removal, the depalletizer processes items individually or in batches. Different machines use mechanical arms, magnets, or suction based on materials handled. Empty pallets are conveyed away while products move to next-stage processing.

Considerations When Selecting Depalletizers

Manufacturers offer customized depalletizer systems. Choosing the right model impacts daily operations significantly. Key factors include:

Speed

Speed and reliability remain priorities in depalletizer technology. Conventional models excel in high-speed tasks, while robotic versions offer greater flexibility and precision. Ideal depalletizer speed typically exceeds product input speed by 20%. Manual models suit slower operations transitioning to automation.

Product Types

Handling varied products presents unique challenges. Conventional models work best with uniform packages, while robotic versions manage diverse packaging autonomously.

Floor Space

Space efficiency matters in packaging operations. Traditional high-level models require more room than low-level versions (30% less space). Robotic models adapt to compact spaces based on configuration.

Safety

Conventional depalletizers ensure safety through restricted access. Robotic versions often need external safety enclosures.

Plant Design

High-level models suit receiving docks, while low-level versions reduce costs near bottle cleaning stations.

In-Feed

Both conventional and robotic models support upper/lower floor in-feed, with conventional versions performing best at upper levels.

Budget

High-level models involve greater purchase/setup costs than low-level versions integrated with existing conveyors.

Maintenance

Conventional models need routine maintenance by qualified mechanics. Robotic versions require specialized knowledge for end-arm tool maintenance.

Flexibility

Systems vary in flexibility, with robotic/hybrid models handling mixed-load pallets through programmable controls and diverse end-effectors.

Chapter 2: Depalletizer Types

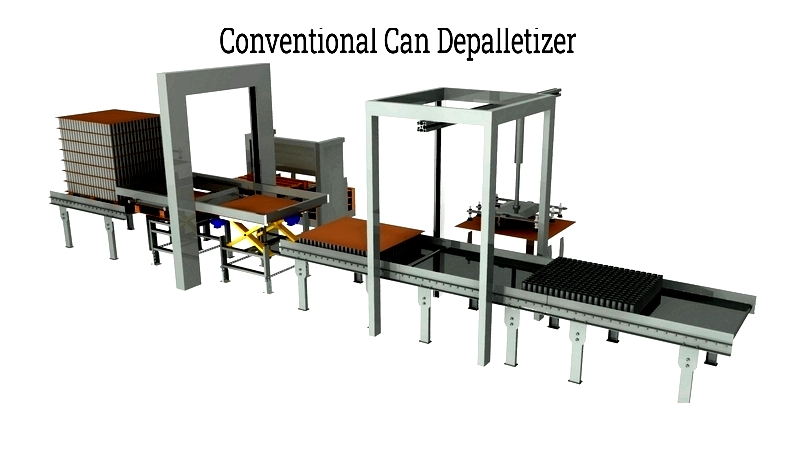

Conventional Depalletizers

These mechanical systems efficiently transfer product layers from pallets to conveyors using hydraulics, pneumatics, or sweeping mechanisms. Available in automatic/semi-automatic configurations with accessories like layer pad grippers and PLC controls, they offer reliable throughput without advanced robotics.

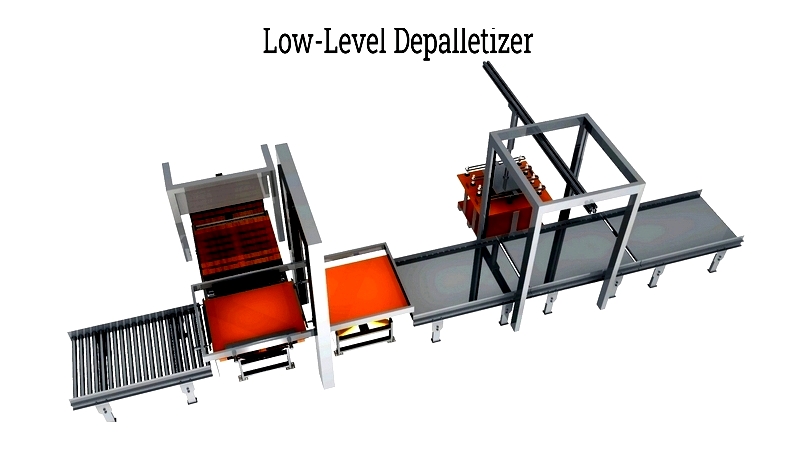

Low-Level Depalletizers

Cost-effective floor-level solutions handle bulk containers in space-limited facilities. Their compact design features mechanical pushers for gentle layer transfer to conveyors, with programmable controls and safety features reducing training/maintenance time.

High-Level Depalletizers

Designed for high-speed operations, these systems receive pallets via overhead infeed, handling up to four layers/minute. Their robust construction suits bottling lines and bulk container handling, with servo-controlled arms for delicate products.

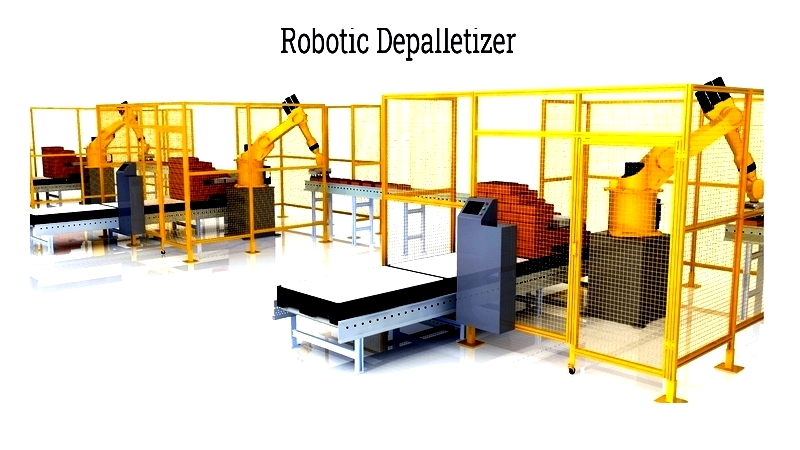

Robotic Depalletizers

Advanced systems offering flexibility and precision across industries. Capable of 1,900 cycles/hour, they handle diverse loads with specialized end-effectors. Machine vision enables mixed-load handling, with AI adapting to new products autonomously.

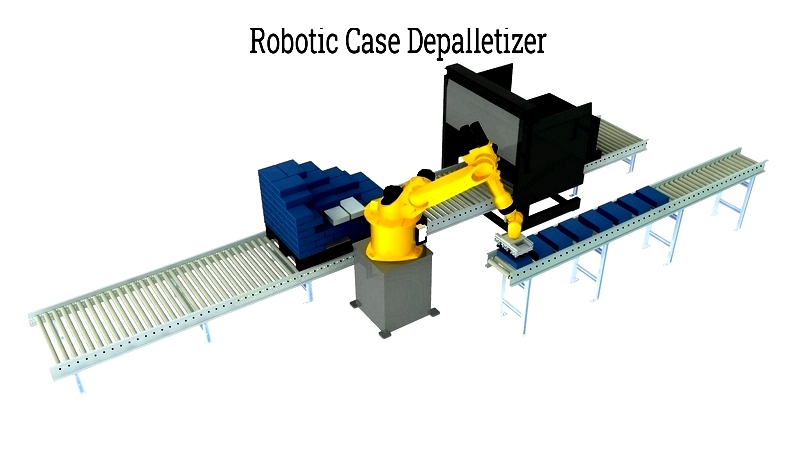

Robotic Case Depalletizers

Specialized in carton/box handling with vision-guided precision. These systems process layers methodically, stacking pads and returning empty pallets automatically. Ideal for high-mix environments with frequent changeovers.

Robotic Magnetic Depalletizers

Designed for ferrous metal containers using industrial-grade magnets. These systems ensure safe transfer of metal cans/jars, with stainless construction meeting food-grade requirements in F&B/pharmaceutical applications.

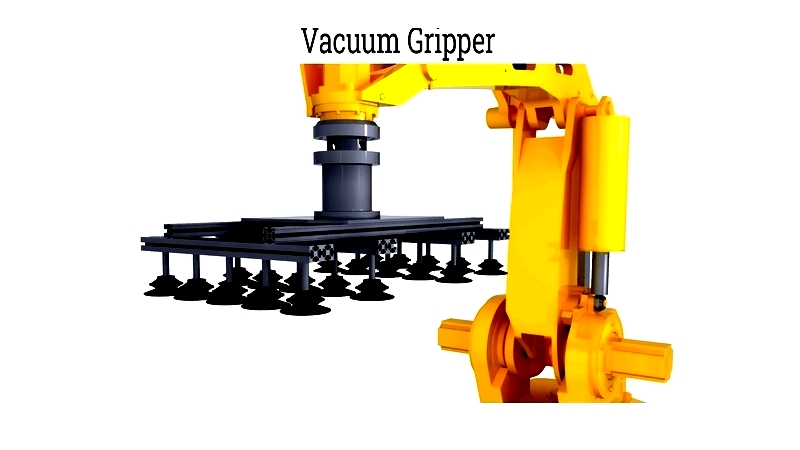

Robotic Vacuum Depalletizers

Utilizing vacuum gripping technology for case/carton handling. Suction cups provide gentle lifting for delicate items, with integration options for vision inspection to improve accuracy.

Ideal for e-commerce and CPG industries, these systems maximize throughput while reducing labor requirements throughout supply chains