Introduction

This article offers a comprehensive overview.

Continue reading to explore key questions such as:

- What are Worm Gears?

- How Worm Gears Are Manufactured

- Different Types of Worm Gears

- Applications of Worm Gears

- And more...

Chapter One - Understanding Worm Gears

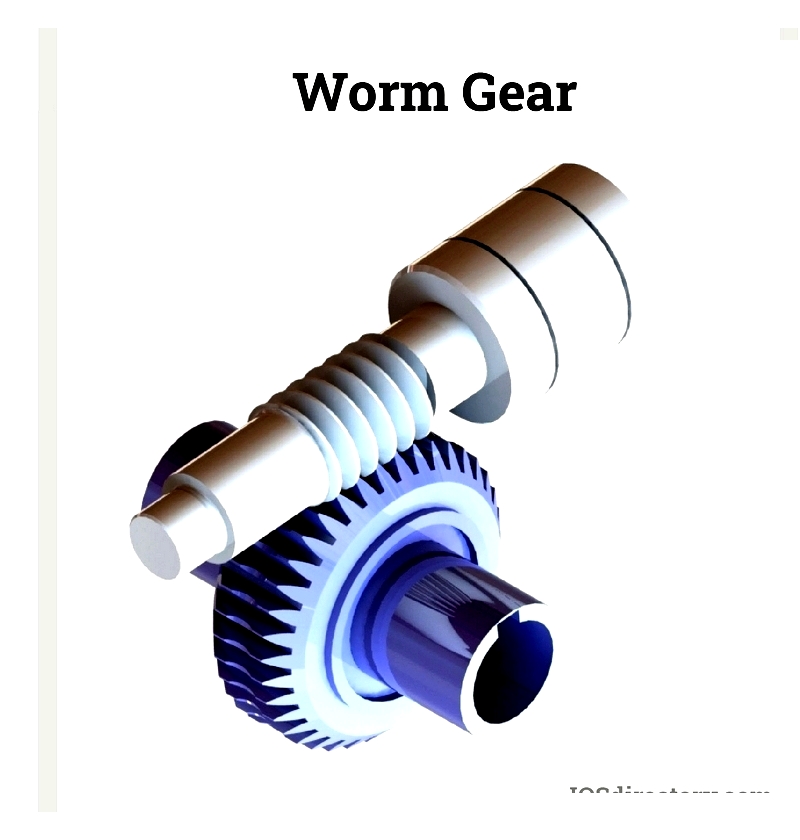

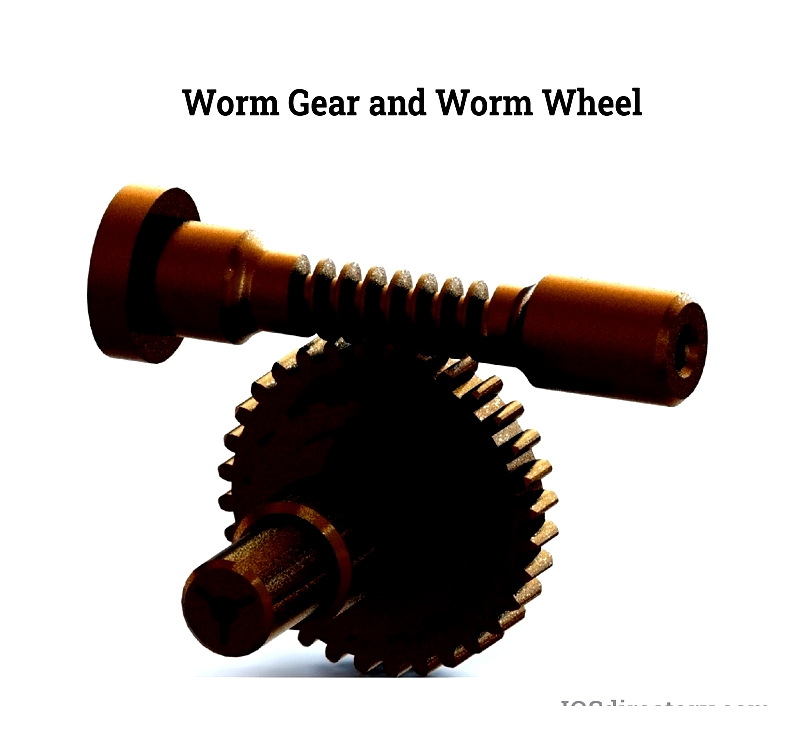

Worm gears are specialized staggered shaft gears that transfer motion between shafts via threaded cylindrical rods, enabling speed reduction. This system consists of two key components: the worm and the worm wheel. Speed reduction occurs through the interaction between the worm's threads and the worm wheel's teeth.

Worm gears offer benefits like reduced noise and vibration while maintaining a compact design. Made from hardened metals, they ensure durability and performance despite generating significant heat.

Chapter Two - Worm Gear Manufacturing

As one of the most compact gearing systems, worm gears play a crucial role in modern power transmission. Known for high-ratio speed reduction and directional change, they excel in industrial automation, robotics, and heavy machinery. Their compact design allows installation in tight spaces while delivering smooth, quiet operation under heavy loads. When paired with a compatible worm wheel, they provide excellent torque transfer and anti-backlash performance, making them ideal for automotive, aerospace, packaging, and material handling applications.

The primary manufacturing method is hobbing, a precision machining process using a gear-cutting tool called a hob. Additional techniques include turning, high-precision milling, and finishing grinding. Advanced CNC machines ensure dimensional accuracy and repeatability in modern worm gear production.

Worm Gear Manufacturing Processes

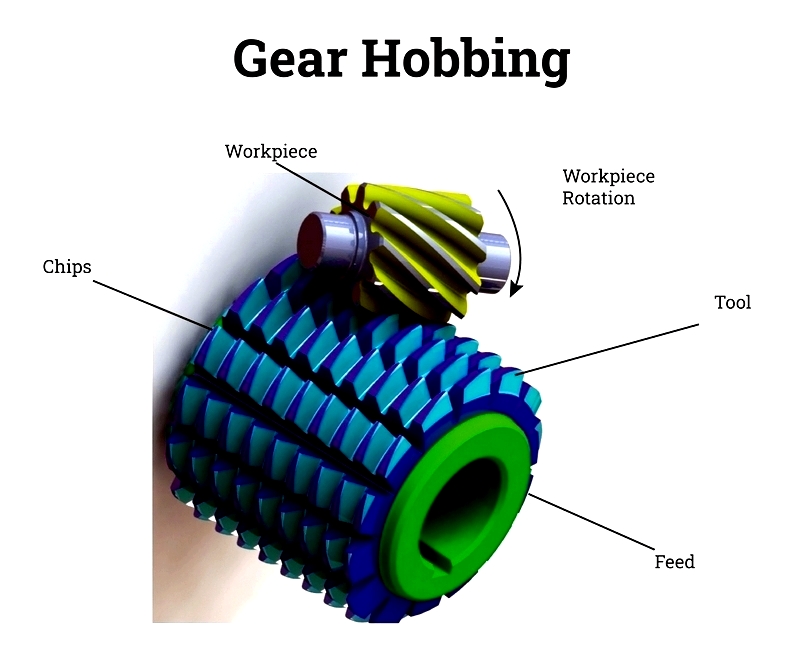

Hobbing

Hobbing is the main manufacturing process, especially for high-volume production. This cold working forging process uses customized hobs to create precise gear teeth profiles. The hob, typically made of hardened high-speed steel or carbide, forms a helical cutter that produces gears with tight tolerances and smooth finishes.

Modern automated hobbing machines feature dual spindles - one for the gear blank and another for the hob - ensuring synchronized cutting and uniform tooth formation. They can produce gears ranging from miniature medical components to heavy industrial equipment.

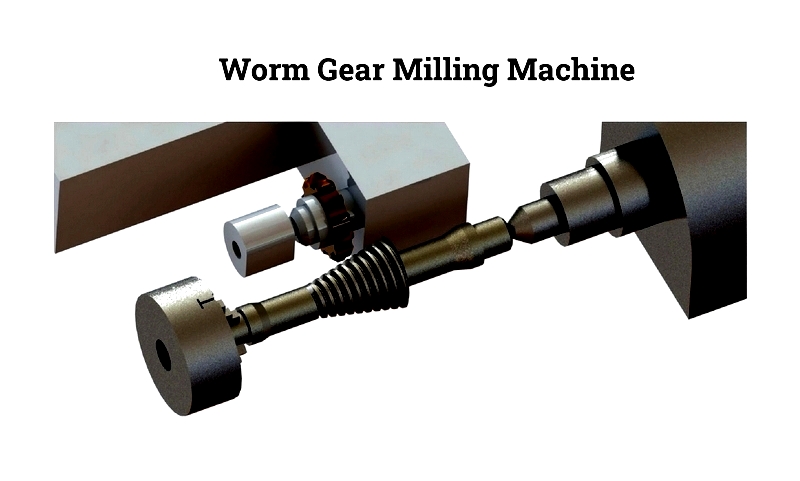

Milling

Milling creates gear teeth using precision cutters on specialized machines with indexing tables. This method suits prototyping, small batches, or custom applications where hobbing isn't feasible. CNC milling has improved precision and speed, meeting strict industry standards.

Accurate setup is crucial, as misalignment affects power transmission efficiency and noise levels. Proper indexing ensures uniform tooth cutting according to design specifications.

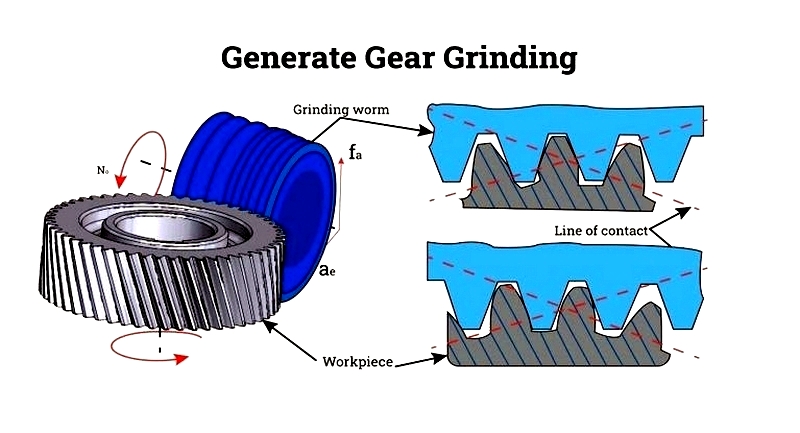

Grinding

Grinding is a finishing process that creates smooth surfaces on hardened materials. This hard finishing method refines gear teeth to final dimensions, improving performance in high-load or high-speed applications.

Multi-axis grinders with abrasive wheels precisely cut worm threads and gear teeth through coordinated movements. This enhances load capacity and efficiency in automotive transmissions, robotics, and motion control systems.

Gear Types

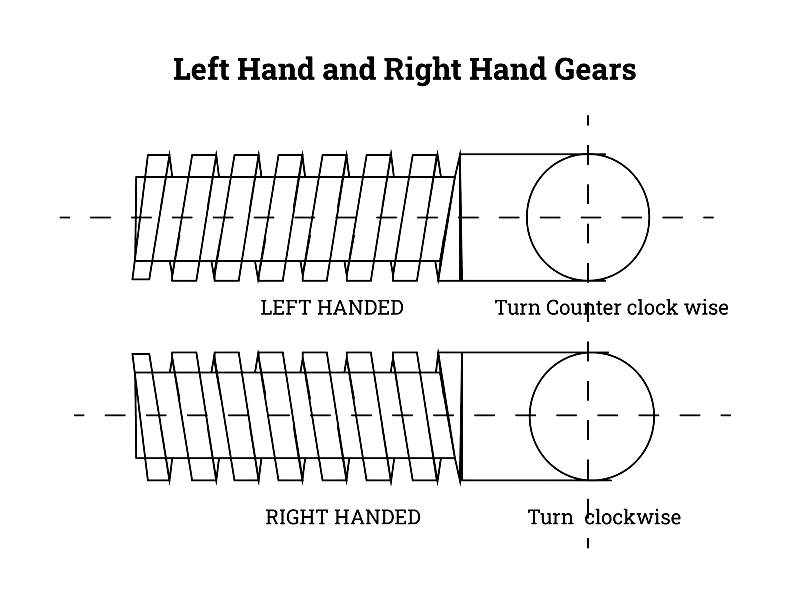

Worm gears feature a worm and worm wheel designed for power transfer between perpendicular shafts. They come in three main types: spur, left-hand helical, and right-hand helical, selected based on transmission direction requirements.

The helical design ensures efficient engagement with the worm wheel, reducing backlash and noise. Common materials include bronze, steel, and specialized alloys chosen for durability and wear resistance. Proper lubrication and surface treatments maintain performance in demanding applications.