Introduction

This is the internet's most comprehensive guide to cooling towers.

You'll learn about:

- How cooling towers operate

- Their components and functions

- Different types: classified by air flow generation, air-to-water flow, heat transfer method, and construction

- Performance influencing factors

- Mechanical maintenance procedures

- Water treatment methods

- Practical applications

- And additional valuable information

Chapter 1: What is a Cooling Tower and How Does It Work?

Cooling towers are specialized heat exchangers that remove water's excess heat primarily through evaporative cooling as water interacts with air. In addition to evaporation, cooling occurs through sensible heat transfer due to the temperature difference between air and water. Unlike conventional heat exchangers like shell-and-tube or plate types that rely on conduction and convection, cooling towers facilitate direct contact between water and air.

Before exploring further topics, it's helpful to understand some fundamental cooling tower terminology.

Cooling Range

The temperature difference between water entering and exiting the cooling tower.

Cooling Load

The rate at which heat is removed from the water.

Make-up

Fresh water added to compensate for evaporated water loss.

Drift

Small water droplets carried away by the airstream during water-air contact.

Plume

The visible exhaust stream of warm air and water vapor from the tower.

Approach

The difference between exiting water temperature and incoming air's wet bulb temperature.

Wet Bulb Temperature

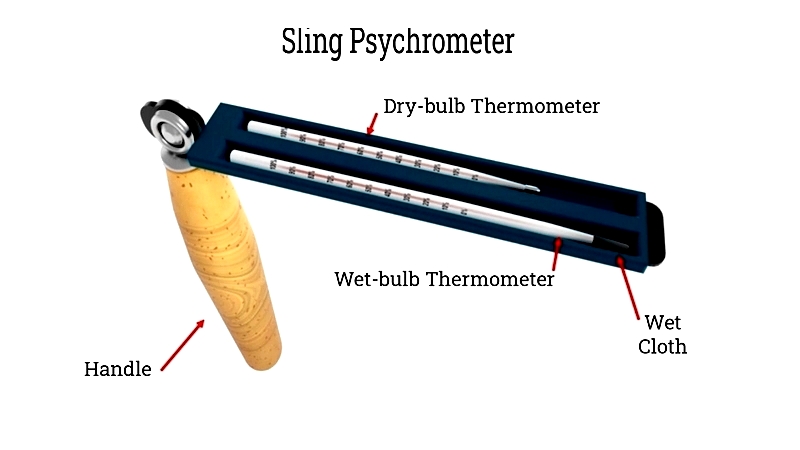

The lowest temperature air can reach through evaporative cooling at 100% humidity. Measured using a psychrometer with a moistened thermometer bulb exposed to airflow, it's typically lower than dry bulb temperature depending on humidity.

Blowdown

Controlled water removal to eliminate accumulated solids from evaporation and bacterial growth.

Recirculation

When exhaust air mixes with incoming air, reducing cooling efficiency.

Chapter 2: Cooling Tower Components and Their Functions

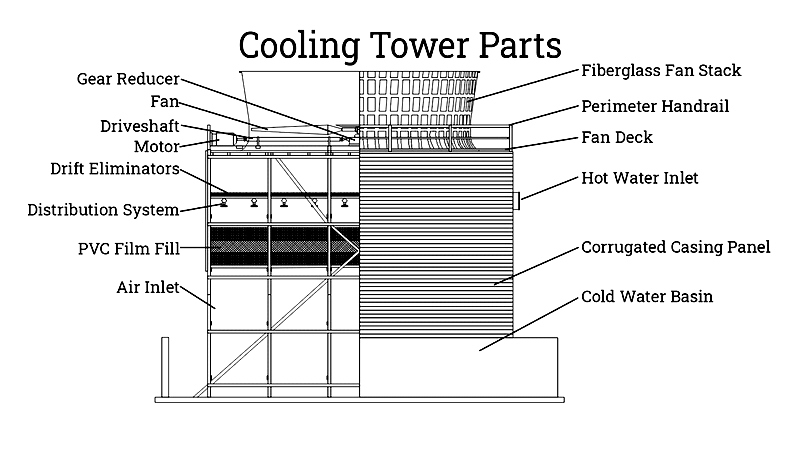

Understanding cooling tower components and their functions is crucial for optimizing efficiency, longevity, and performance. Components fall into three categories: structural, mechanical, and electrical. Structural elements include static equipment like basins, frameworks, fan decks, casings, and louvers that provide support and containment. Mechanical parts comprise rotating equipment such as fans, driveshafts, and speed reducers. Electrical systems consist of motors and control circuits that automate operations.

Fill

Also called wet deck or fill media, this critical component maximizes air-water contact area to enhance cooling efficiency while minimizing airflow resistance. Common types include splash fill and film fill, each suited for specific applications and water conditions.

Distribution System

Design varies between cross-flow and counter-flow towers. Cross-flow systems use gravity-fed distribution basins above the fill, while counter-flow towers employ pressurized spray nozzles for even water distribution over vertical fill.

Drift Eliminators

These devices prevent water droplet escape by forcing air direction changes, conserving water and reducing environmental contamination risks while meeting regulatory requirements.

Louvers

Positioned at air intakes, they prevent water splash-out, reduce noise, and block debris while optimizing airflow in cross-flow designs.

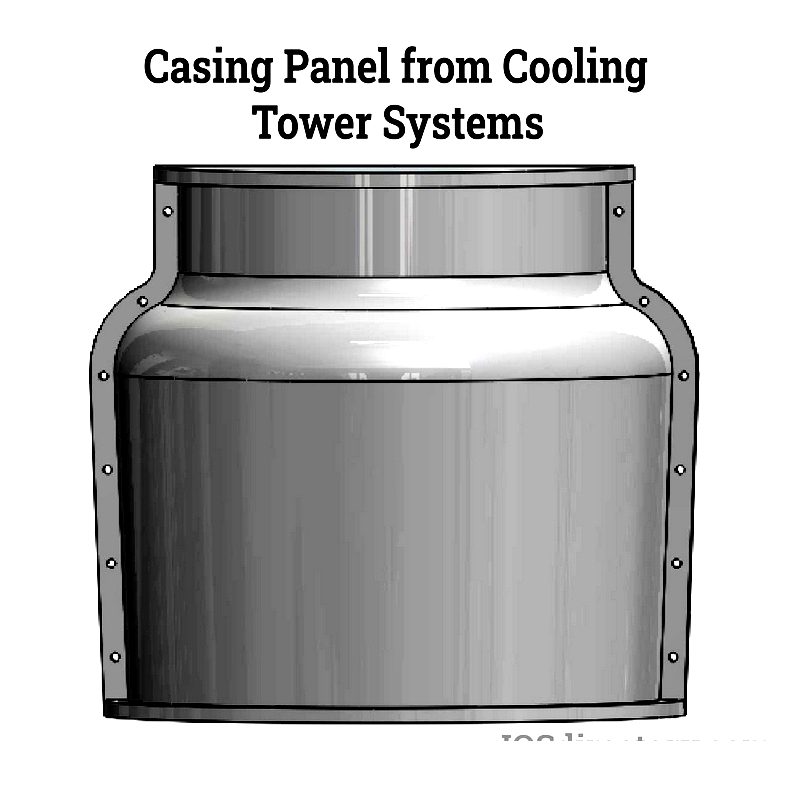

Casing

The external shell made from durable materials like FRP, stainless steel, or plastics that protects internal components from weather and chemical exposure.

Fan System

Comprising fan, motor, driveshaft, and speed reducer, this system generates necessary airflow. Speed reducers increase torque for large fans, making designs more cost-effective.

Fan Stack

This component surrounds the fan to ensure smooth airflow and prevent warm air recirculation, improving efficiency.

Fan Deck

A structural platform supporting fan cylinders and providing maintenance access.

Valves

Essential for water control and maintenance, including:

- Isolation valves for flow regulation

- Flow-control valves for balancing water distribution

- Make-up valves for automatic water replenishment

Collection Basin

The base reservoir collecting cooled water, requiring regular maintenance to prevent sediment buildup and corrosion.

Distribution Basin

Ensures even hot water dispersion across fill media in cross-flow towers.

Structural frame

The supporting framework typically made from durable materials like concrete, treated wood, or corrosion-resistant metals.

Selecting appropriate components depends on capacity, water quality, space, and efficiency requirements. Understanding their relationships is key for specification, maintenance, or upgrades in various applications.