Introduction

This article provides an in-depth examination of electric actuators.

It covers detailed information on various aspects including:

- Working Principles of Electric Actuators

- Different Varieties of Electric Actuators

- Practical Uses and Advantages of Electric Actuators

- Additional Relevant Information

Chapter 1: Fundamental Principles of Electric Actuators

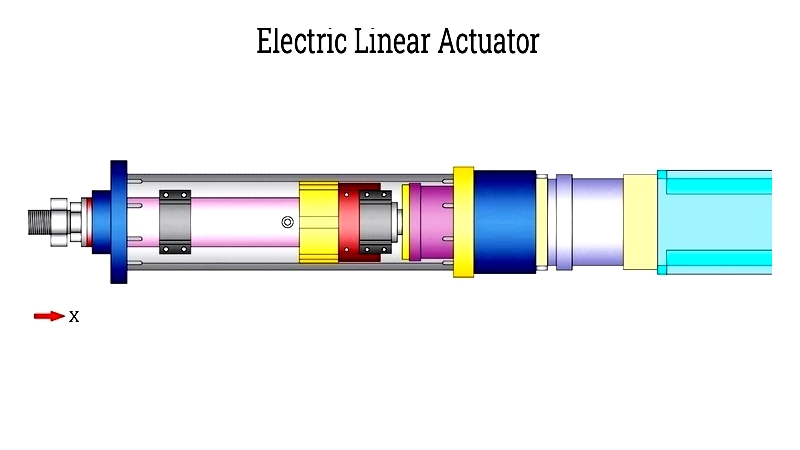

This chapter examines the core concepts of electric actuators, including their manufacturing processes, key components, operational mechanisms, and performance characteristics.

Definition of Electric Actuators

Electric actuators are devices that convert electrical energy into mechanical force to move loads or perform tasks such as clamping, using an electric motor as their power source.

The electric motor generates rotational motion in the spindle or rotor. Within the actuator, a helical screw connects to the motor spindle through the drive shaft, rotating inside a ball screw nut.

Production of Electric Actuators

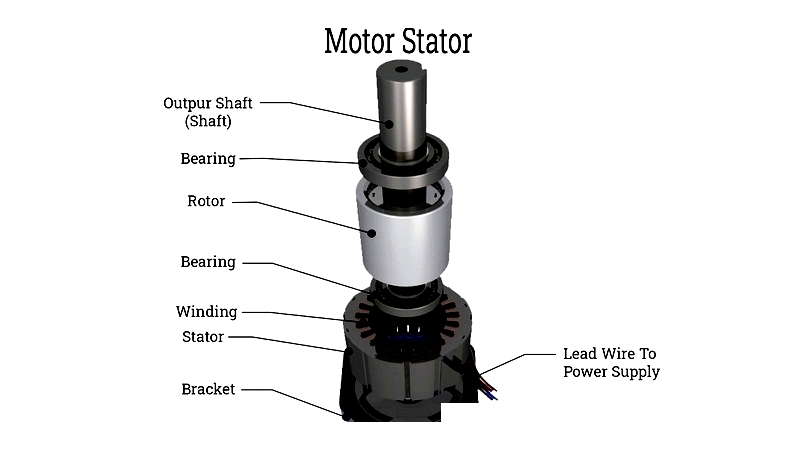

Manufacturing begins with the electric motor, consisting of two main parts: the stationary stator (a permanent magnet) and the rotating rotor positioned at the stator's center.

Each component undergoes precision fabrication on automated assembly lines, with continuous monitoring from rotor winding to shaft screw installation. Quality control rigorously tests every production batch. Simultaneous production of different motor parts enhances efficiency, streamlining the assembly of complete linear actuators.

Mechanical arms and conveyor systems transport materials between production stages. After automated assembly, technicians complete final assembly following engineering specifications, with quality inspections at each step.

Quality Assurance

Completed actuators undergo first article inspection in Quality Control, verifying dimensions and compliance with standards. Initial units undergo stress testing for IP ratings, temperature tolerance, and duty cycle performance.

Approved batches proceed to distribution, where engineers recheck specifications and inspect for shipping damage before entering inventory. Final testing occurs before secure packaging and shipment to customers.

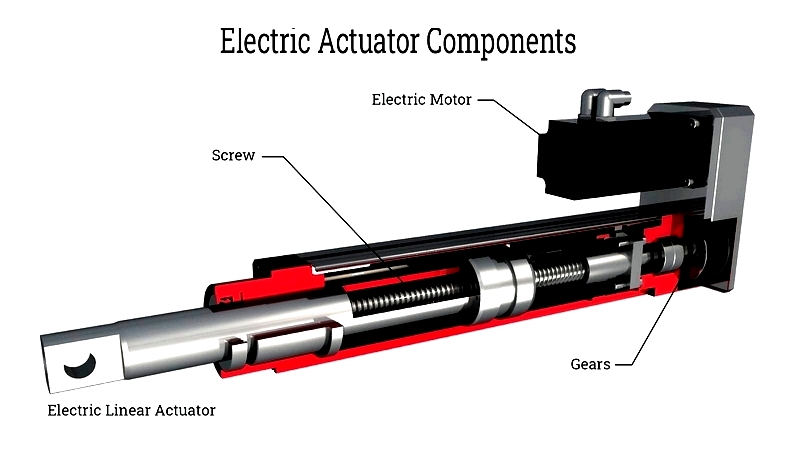

Electric Actuator Components

This section details the various parts comprising an electric actuator.

Front/Rear Clevis

A U-shaped metal bracket with end holes for fasteners, enabling secure mounting to applications through front and rear fittings.

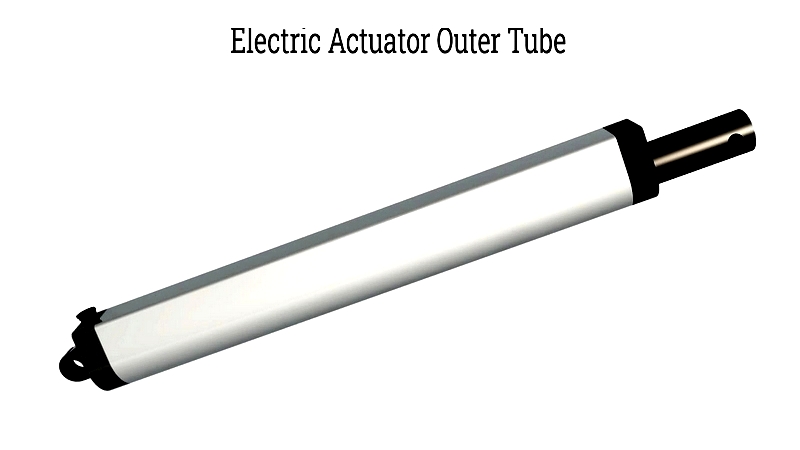

Outer Tube

An extruded aluminum cover protecting internal components and housing all actuator mechanisms.

Inner Tube

Also called the extension or drive tube, this aluminum/stainless steel component houses the spindle during retraction, connected to the threaded drive nut for linear movement.

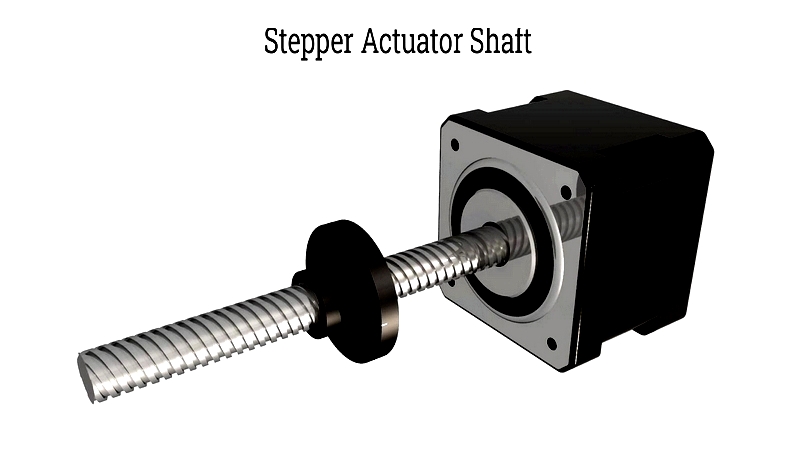

Spindle Assembly

A rotating steel rod (also called lead screw) that controls inner tube movement, available with different thread patterns for varying speed and load requirements.

Safety Stop

A physical limit preventing inner tube overextension at the spindle's end.

Wiper Seal

Located at the outer tube's end, this component prevents contaminant entry while maintaining proper sealing between tubes, affecting the actuator's IP rating.

Drive Nut

This spindle-mounted component, attached to the inner tube, facilitates extension/retraction. Materials vary (plastic/metal), with optional keying to prevent tube rotation.

Limit Switches

Electrical switches stopping motor current at full extension/retraction, preventing overtravel while providing position signaling capability.

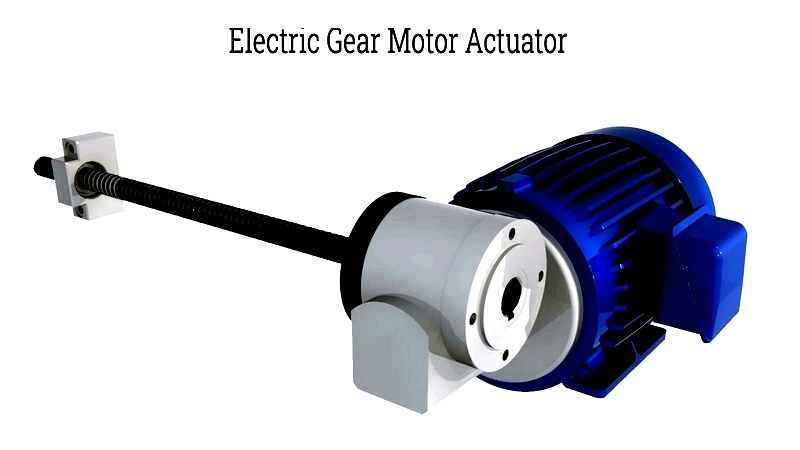

Gear Systems

Plastic or steel gears modifying speed relationships between driving and driven components, with the motor-connected gear being the drive gear.

Motor Housing

Protective enclosure for gear motor and internal components, typically constructed from durable plastic.

DC Motor

The actuator's power source, with brushed motors being most common. Contains several key elements:

Motor Stator

Stationary outer section comprising housing, end caps, and permanent magnets creating the rotor's magnetic field.

Rotor

Rotating inner component (armature) containing shaft, laminates, windings, and commutator.

Commutator

Shaft-mounted plates connecting to electromagnet coils, reversing polarity to maintain continuous rotation.

Carbon Brushes

Conductive elements transferring current to the rotor via sliding contact.

Motor Shaft

Connects the gear motor to the DC motor's stator base.

Feedback Sensors

Devices providing position data to control systems for precise operations like synchronization. Available sensor types include:

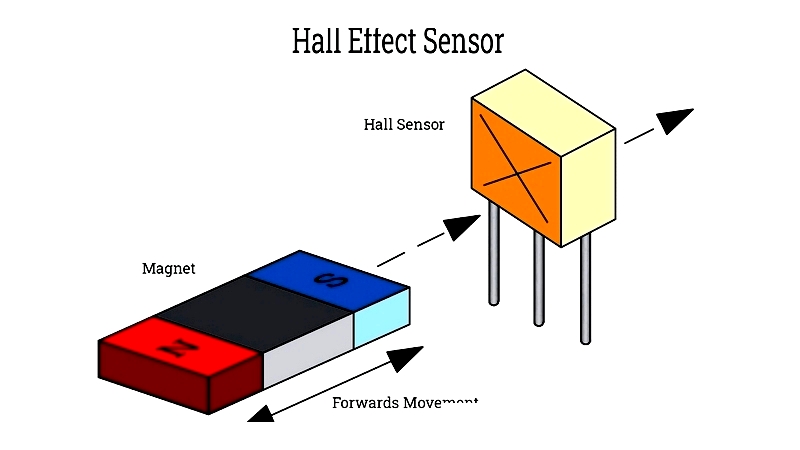

Hall Effect Sensor

Generates voltage output in response to magnetic fields, enhancing actuator accuracy and reliability.

Potentiometer Sensor

Adjusts electrical output via wiper movement across resistive elements, with positions corresponding to actuator stroke.

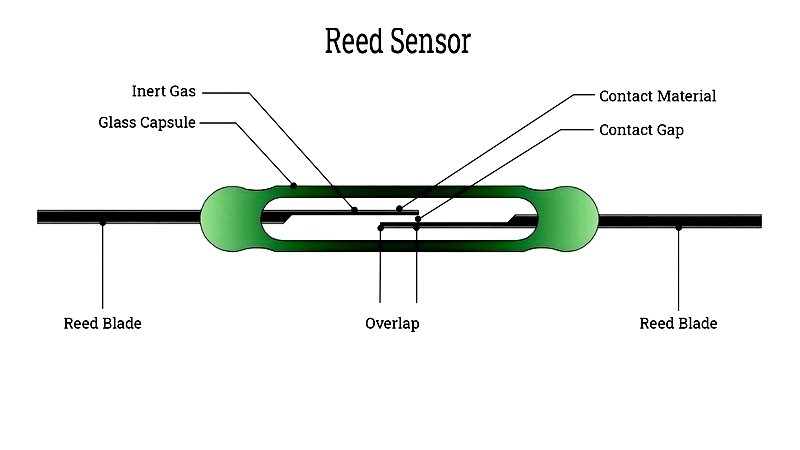

Reed Sensor

Magnetic switch with ferrous contacts in sealed glass, closing under magnetic influence to interrupt power.

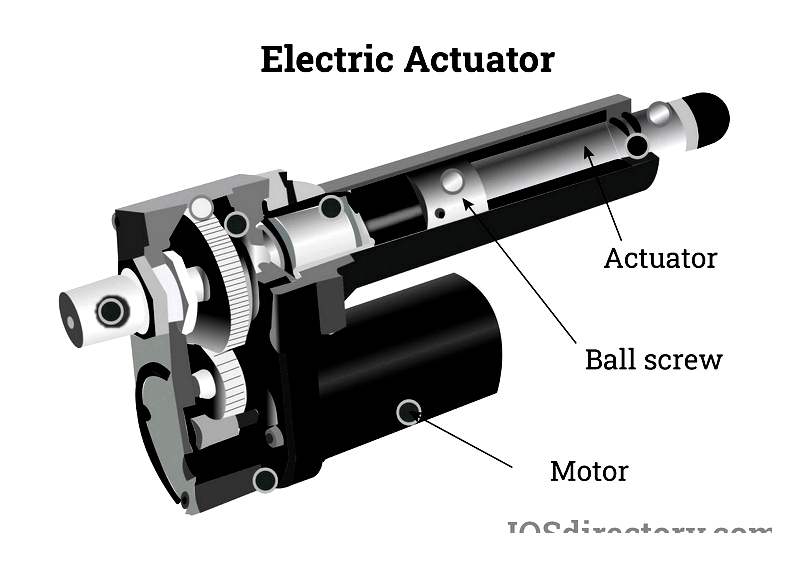

Operational Mechanism

The electric motor creates rotary motion in the spindle, which connects to a helical screw via the drive shaft.

Spindle rotation moves the ball screw nut longitudinally along the helical screw, converting rotation into linear motion through connection with a hollow piston rod. Direction depends on motor rotation (clockwise/counterclockwise).

Electric drives control movement speed, while feedback systems enable precise positioning, pauses, or return sequences. Torque output correlates with motor power, determining force capability.

Chapter 2: Varieties of Electric Actuators

Electric actuators serve vital roles in industrial