Introduction

This article provides an in-depth exploration of lift tables.

You will learn about various aspects including:

- What is a lift table?

- Different types of lift tables

- How lift tables function

- The advantages of using lift tables

- And much more…

Chapter One – What is a Lift Table?

A lift table is a versatile platform designed to support materials and adjust their height for various applications and user needs. It features a sturdy base frame that can be floor-mounted, pit-installed, or equipped with casters for mobility. Most lift tables use hydraulically powered scissor legs to ensure smooth vertical movement for precise positioning and operation.

These tables offer adaptable workspaces for industrial tasks like parts sorting, repairs, tool organization, or creating flexible work areas in confined spaces. Designed with ergonomics in mind, lift tables promote comfortable and efficient working environments.

Chapter Two – Types of Lift Tables by Power Source and Lifting Mechanism

Lift tables are essential industrial equipment for moving, elevating, and positioning heavy loads in warehouses, manufacturing plants, and distribution centers. They provide a cost-effective and safe material handling solution that reduces ergonomic injuries, boosts productivity, and optimizes space utilization. By enabling workers to operate at ideal heights, lift tables enhance both employee well-being and operational efficiency.

Available in diverse designs, lift tables are categorized by power source (manual, pneumatic, hydraulic, or electric) and lifting mechanism. Understanding these classifications helps businesses select the right equipment based on operational needs, lift height requirements, duty cycles, and specific applications.

Types of Lift Tables By Power Source

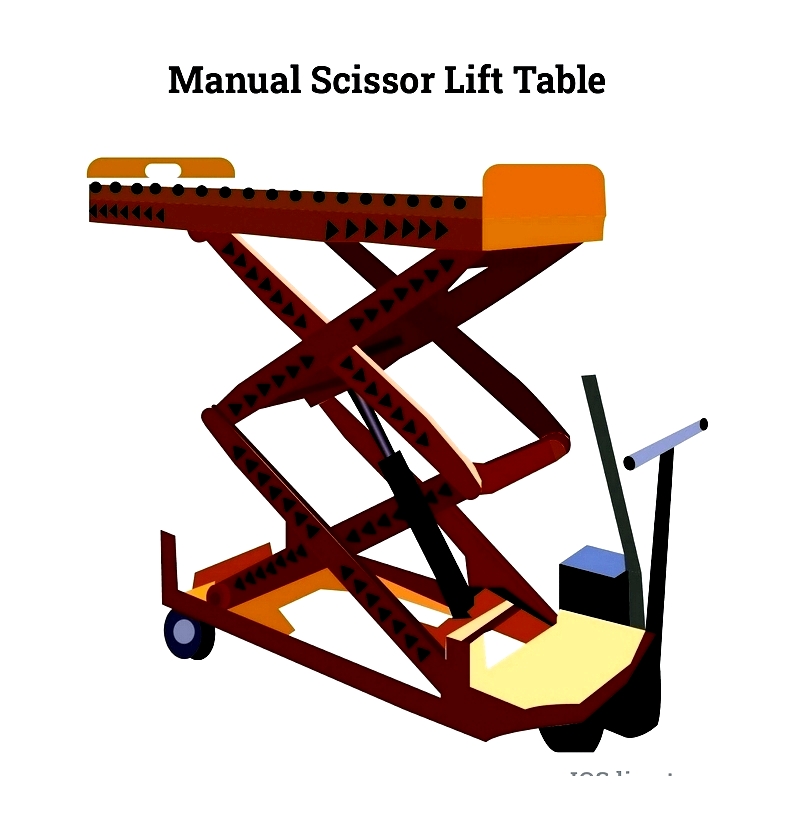

Manual Lift Tables

Manual lift tables are simple, durable solutions for light-duty applications requiring infrequent lifting. Operated by hand crank, ratchet, screw jack, or hydraulic pump, they are ideal for assembly lines and packaging stations where power access is limited.

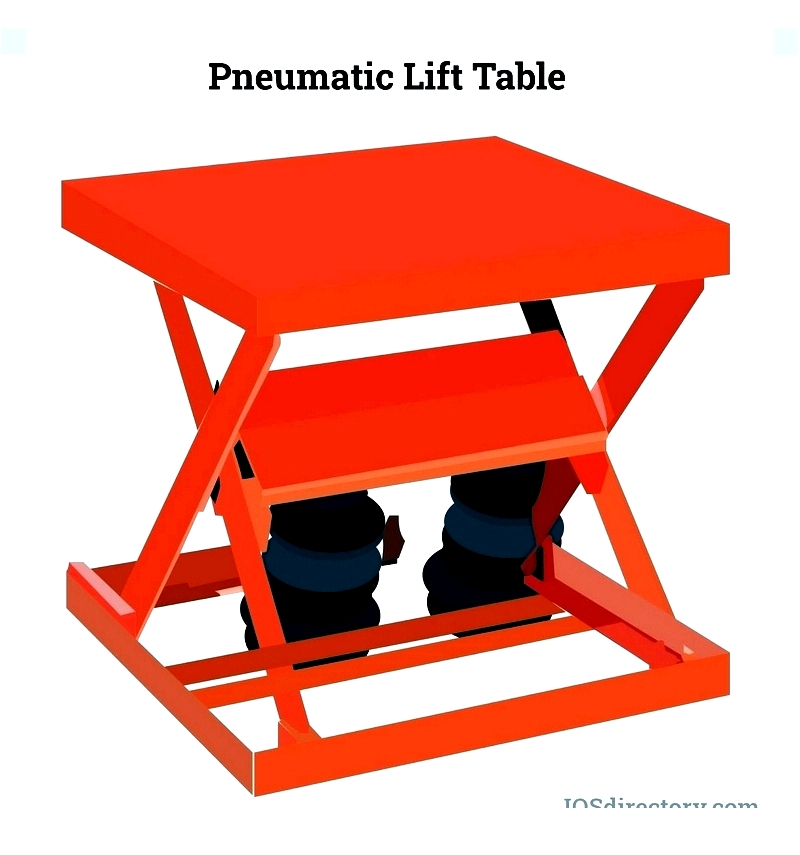

Pneumatic Lift Tables

Pneumatic lift tables use compressed air for lifting, making them energy-efficient and suitable for clean environments. Their fluid-free design makes them perfect for food processing, pharmaceuticals, and electronics manufacturing where contamination must be avoided.

Hydraulic Lift Tables

Hydraulic lift tables, powered by fluid pressure, are industry standards for heavy-duty applications. They offer high capacity, durability, and smooth operation, with options for electric, manual, or battery power.

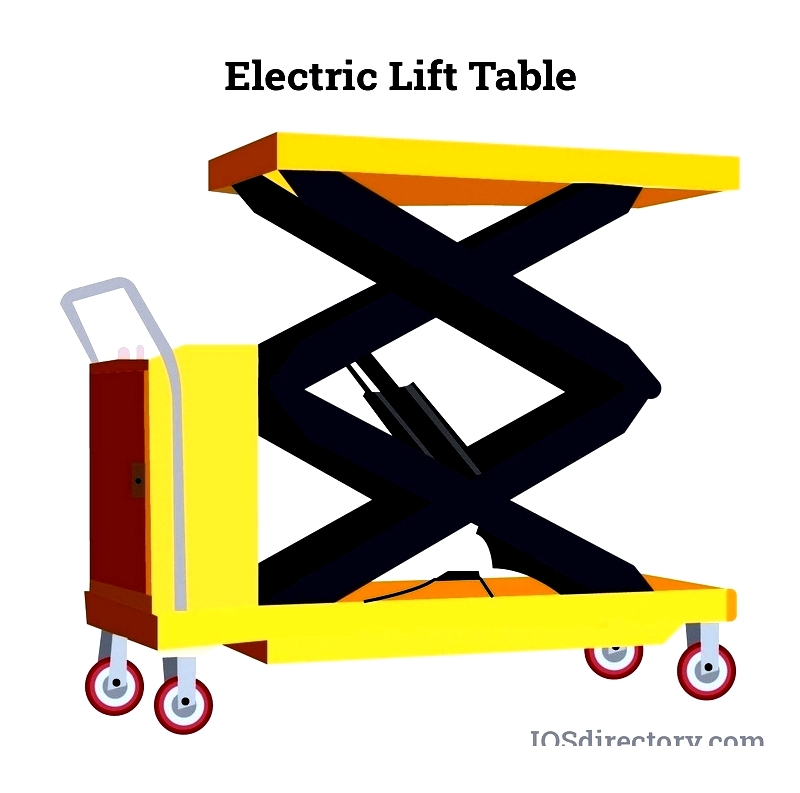

Electric Lift Tables

Electric lift tables provide push-button operation with DC or AC motors. Suitable for frequent adjustments, they are ideal for assembly lines, laboratories, and automated workstations.

Lift Table Types By Lifting Mechanism

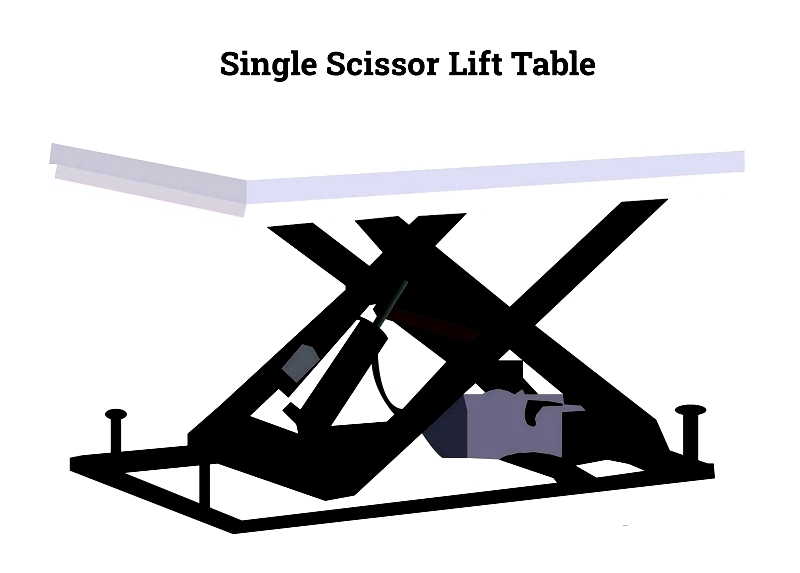

Scissor Lift Tables

Scissor lift tables use pantograph mechanisms for vertical movement, available in single, double, or multi-stage configurations for various load capacities.

Screw Scissor Lift Tables

Screw-driven lift tables offer precise, incremental height adjustment without hydraulic fluid, ideal for laboratories and precision work.

Belt Drive Lift Tables

Belt-driven lift tables provide quiet, low-maintenance operation, suitable for electronics manufacturing and automated assembly lines.

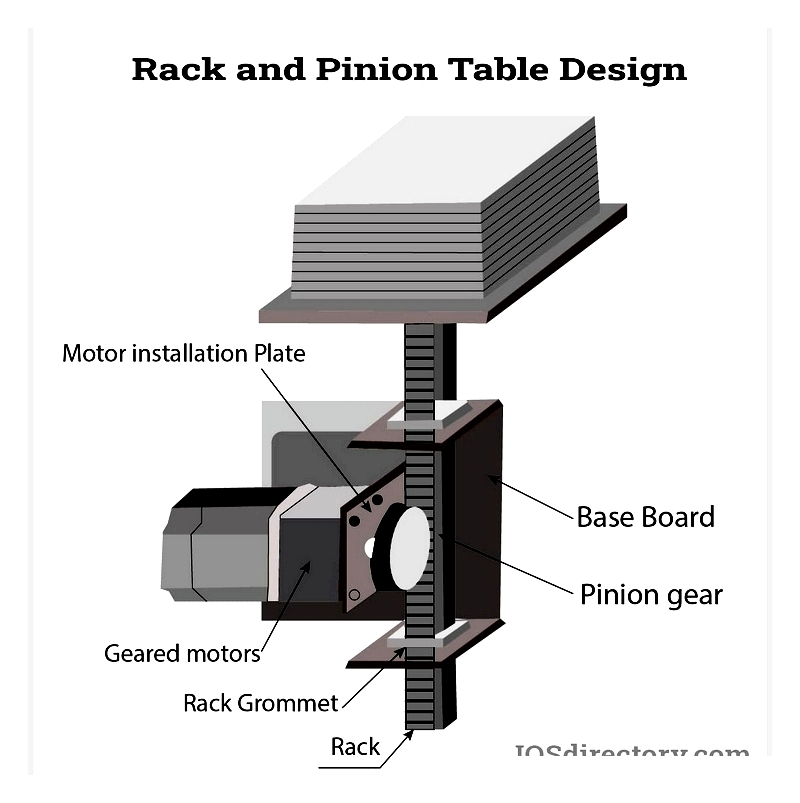

Rack and Pinion Tables

Rack and pinion lift tables handle extremely heavy loads with robust construction, commonly used in foundries and machine shops.

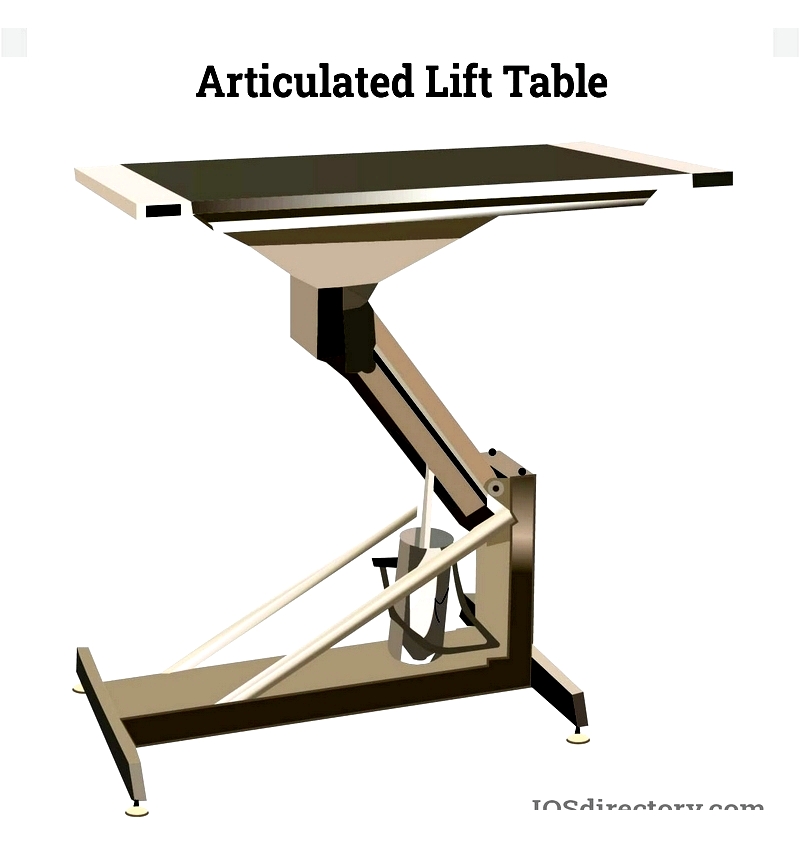

Articulated Lift Table

Articulated lift tables offer versatile movement for technical work and light assembly, with multi-link lifting mechanisms.

Choosing the Right Lift Table

When selecting a lift table, consider load capacity, lift height, platform size, power source, workspace layout, usage frequency, and safety features. Match the table type to your specific environment and operational requirements for optimal performance.